- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- templates for plastics extrusion

Results for

Templates for plastics extrusion - Import export

MING XIAO MANUFACTURING CO., LTD

China

Ming Xiao Manufacturing Co Ltd is specialize in Plastic extrusion profiles,pipes, rods, rails, LED lampshade,Wiring trunking, Speaker body, Kinds of Shells and slides,we can produce plastic extrudsion products from materials of PVC, ABS, PP,PE,PC,PMMA, AS /PE... The extrusion molding service is to heat the plastic material and make it in the state of viscous flow. Under the action of pressure, the plastic mold is used to form a continuum that is similar to the shape of the die. Then the cooling is made to form a glass state, and the plastic products with a certain geometry and size are obtained by cutting. The Plastic Extrusion profiles widely use for auto parts, light rail train fittings, lamps and lanterns, refrigeration industry, household electrical appliances, stationery, warehousing and other enterprises to provide quality support services. If you need any plastic extrusion profiles,welcome send your drawings and samples to us for a quote.

Request for a quote

W. MÜLLER GMBH

Germany

Space-saving in a vertical (e.g. for retrofitting) but also in a horizontal version, our extruders are available in many variations for your specific needs. For applications with larger throughputs, we have high-quality extruders with heat-separated feed zone cooling, which deliver a high-quality melt for the further process. We also offer coordinated screw designs for special materials such as PVC, PA, EVOH, E-PET or adhesive layers.

Request for a quote

ALPIN RUBBER AND PLASTIC TECHNOLOGIES

Turkey

At our company, we are dedicated to delivering top-quality custom molding and extrusion services characterized by exceptional craftsmanship. With meticulous attention to detail, we specialize in producing rubber parts and components tailored precisely to meet our customers' unique requirements. From rubber seals and grommets to O-rings and bushings, we offer a comprehensive range of customized solutions to suit diverse applications.

Request for a quote

MING XIAO MANUFACTURING CO., LTD

China

Ming Xiao produce extrusion TPR / TPE / PU / TPU soft profiles. TPR is a thermoplastic rubber material, which is generally modified with SBS base material (in a narrow sense, this is a way to distinguish it from SEBS modified TPE), and is usually made into spherical particles, ellipsoidal particles and round strips. Glossy transparent or white particles. TPR material has the characteristics of rubber, with good elasticity, resilience and shrinkage, abrasion resistance and weather resistance. However, the processing method is simpler than that of rubber. It can be processed and produced by an ordinary injection molding machine. It can also be used for plastic toughening modification. It can be encapsulated or composite injection molded with PP, ABS and other materials. It does not need to be vulcanized like rubber. ,Increase productivity. In addition, TPR is a new type of environmentally friendly material, non-toxic, tasteless, and recyclable, which is a huge advantage over rubber.

Request for a quote

MING XIAO MANUFACTURING CO., LTD

China

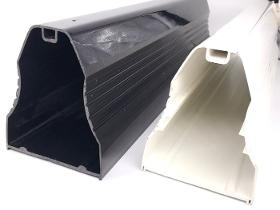

Ming Xiao Manufacturing Co Ltd is specialize in Plastic extrusion profiles,pipes, rods, rails, LED lampshade,Wiring trunking, Speaker body, Kinds of Shells and slides,we can produce plastic extrudsion products from materials of PVC, ABS, PP,PE,PC,TPE/TPR, AS /PE... The extrusion molding service is to heat the plastic material and make it in the state of viscous flow. Under the action of pressure, the plastic mold is used to form a continuum that is similar to the shape of the die. Then the cooling is made to form a glass state, and the plastic products with a certain geometry and size are obtained by cutting. The Plastic Extrusion profiles widely use for auto parts, light rail train fittings, lamps and lanterns, refrigeration industry, household electrical appliances, stationery, warehousing and other enterprises to provide quality support services. If you need any plastic extrusion profiles,welcome send your drawings and samples to us for a quote.

Request for a quote

MING XIAO MANUFACTURING CO., LTD

China

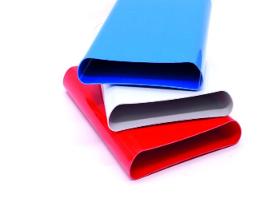

Ming Xiao Mfg is a Chinese plastic extrusion products manufacturer custom making PVC soft and hard co-extrusion profiles according to customer’s design or sample. we can co-extrude profiles by Soft and Hard Co-extruding, 2/3(double or three) colors Co-extruding, 2 materials Co-extruding. We are focus on plastic extrusion custom services for worldwide customers, and have produced more than Thousands of plastic profiles & pipes for foreign clients in the past 15 years. At the same time, we have gained a wealth of experience, and the requirements for product quality have further deepened our understanding. Plastic extrusion products mainly use for auto parts, light rail train fittings, lamps and lanterns, refrigeration industry, household electrical appliances, stationery, warehousing and other enterprises to provide quality support services.

Request for a quote

MING XIAO MANUFACTURING CO., LTD

China

Ming Xiao Manufacturing Co Ltd is specialize in Plastic ABS extrusion profiles, pipes, strips, rods, rails, LED lampshade,Wiring trunking, Speaker body, Kinds of Shells and slides, The extrusion molding service is to heat the plastic material and make it in the state of viscous flow. Under the action of pressure, the plastic mold is used to form a continuum that is similar to the shape of the die. Then the cooling is made to form a glass state, and the plastic products with a certain geometry and size are obtained by cutting. The Plastic Extrusion profiles widely use for auto parts, light rail train fittings, lamps and lanterns, refrigeration industry, household electrical appliances, stationery, warehousing and other enterprises to provide quality support services. If you need any ABS extrusion profiles,welcome send your drawings or samples to us for a quote.

Request for a quote

MING XIAO MANUFACTURING CO., LTD

China

Ming Xiao Manufacturing Co Ltd is specialize in Plastic extrusion profiles,pipes, rods, rails, LED lampshade,Wiring trunking, Speaker body, Kinds of Shells and slides,we can produce plastic extrudsion products from materials of PVC, ABS, PP,PE,PC,PMMA, AS /PE... The extrusion molding service is to heat the plastic material and make it in the state of viscous flow. Under the action of pressure, the plastic mold is used to form a continuum that is similar to the shape of the die. Then the cooling is made to form a glass state, and the plastic products with a certain geometry and size are obtained by cutting. We provide a variety of extrusion process processing, cold extrusion, hot extrusion,Embossing Extruding, two-color co-extrusion, three-color co-extrusion, soft and hard co-extrusion,can meet customer requirements of different products processing needs! If you need any plastic extrusion profiles,welcome send your drawings and samples to us for a quote.

Request for a quote

MING XIAO MANUFACTURING CO., LTD

China

Custom PVC Extrusion Pipes - 20 years of experience in Plastic extruding Services. Ming Xiao Manufacturing Co Ltd is specialize in Plastic extrusion pipes, rods, rails, LED lampshade,Wiring trunking, Speaker body, Kinds of Shells and slides from PVC resins. The extrusion molding service is to heat the plastic material and make it in the state of viscous flow. Under the action of pressure, the plastic mold is used to form a continuum that is similar to the shape of the die. Then the cooling is made to form a glass state, and the plastic products with a certain geometry and size are obtained by cutting. The Plastic Extrusion profiles widely use for auto parts, light rail train fittings, lamps and lanterns, refrigeration industry, household electrical appliances, stationery, warehousing and other enterprises to provide quality support services. If you need any plastic PVC extrusion pipes or complicates structured profiles,welcome send your drawings and samples to us for a quote.

Request for a quote

MING XIAO MANUFACTURING CO., LTD

China

Ming Xiao Manufacturing Co Ltd is specialize in Plastic extrusion profiles,pipes, rods, rails, LED lampshade,Wiring trunking, Speaker body, Kinds of Shells and slides,we can produce plastic extrudsion products from materials of PVC, ABS, PP,PE,PC,PMMA, AS /PE,TPE/TPR... The extrusion molding service is to heat the plastic material and make it in the state of viscous flow. Under the action of pressure, the plastic mold is used to form a continuum that is similar to the shape of the die. Then the cooling is made to form a glass state, and the plastic products with a certain geometry and size are obtained by cutting. The Plastic Extrusion profiles widely use for auto parts, light rail train fittings, lamps and lanterns, refrigeration industry, household electrical appliances, stationery, warehousing and other enterprises to provide quality support services. If you need any plastic extrusion profiles,welcome send your drawings and samples to us for a quote.

Request for a quote

MING XIAO MANUFACTURING CO., LTD

China

Ming Xiao Mfg specializes in plastic extruding both Rigid and Flexible PVC Profiles and PVC tubing. Finished PVC Extrusions can be fabricated into more complex assembly by hot bending, forming, notching, punching, gluing, riveting and other techniques. We are able to produce almost any component suitable for flexible or rigid PVC extrusion processes. If you have special requirements, we invite you to discuss with us. We are focus on plastic extrusion custom services for worldwide customers, and have produced more than Thousands of plastic profiles & pipes for foreign clients in the past 15 years. At the same time, we have gained a wealth of experience, and the requirements for product quality have further deepened our understanding. Plastic extrusion products mainly use for auto parts, light rail train fittings, lamps and lanterns, refrigeration industry, household electrical appliances, stationery, warehousing and other enterprises to provide quality support services.

Request for a quote

MING XIAO MANUFACTURING CO., LTD

China

Custom Tansparent PC Pipes & PVC Profiles, High transparency, light transmittance up to 92%. Ming Xiao Manufacturing Co Ltd is specialize in Plastic extrusion pipes, rods, rails, LED lampshade,Wiring trunking, Speaker body, Kinds of Shells and slides from PVC resins. The extrusion molding service is to heat the plastic material and make it in the state of viscous flow. Under the action of pressure, the plastic mold is used to form a continuum that is similar to the shape of the die. Then the cooling is made to form a glass state, and the plastic products with a certain geometry and size are obtained by cutting. The Plastic Extrusion profiles widely use for auto parts, light rail train fittings, lamps and lanterns, refrigeration industry, household electrical appliances, stationery, warehousing and other enterprises to provide quality support services. If you need any plastic PC extrusion pipes or profiles,welcome send your drawings and samples to us for a quote.

Request for a quote

LOUISON INDUSTRIES

France

Discover coextruded tape, used in the building and public works and agriculture sectors as reinforcement in a construction operation (e.g. reinforced earth, tutoring...). A combination of textile and plastic, coextrusion is a process that involves melting thermoplastic resins which then cover the textile in the form of threads (high-tenacity polyester threads, for example). Each material brings its own properties to the product. So, according to the specifications we receive, we will incorporate all the characteristics you need: resistance, texture, etc... Note: the plastic residues generated can be transformed into reusable beads, reducing the overall waste produced during the extrusion process.

Request for a quote

TECHNIC MACHINES

Turkey

Our plastic sheet extruder machine lines have different production capacity range and we provide our sheet extrusion machine lines for different plastic sheet products so that we can match with our customer's requirements. We provide our sheet extrusion line for different raw materials such as pvc, pp, ps / polystyrene, pc / polycarbonate, hdpe / ldpe, pet and for other. Plastic Sheet Extruders by Raw Material - PET Sheet Extruder Machine - PP Sheet Extruder Machine - PE Sheet Production Line - PVC Sheet Extruder Line - PC Sheet Extrusion Machine - ABS Sheet Extruder Machine Plastic Sheet Extruders by Final Shapes - Rigid Sheet Extruder Line - Plastic Board Extrusion Machine - Foam Board Extruder Lines - Hollow Sheet Extrusion Machine - Corrugated Sheet Extruder Machine - Honeycomp Board Extruder Machine Just contact with us for other plastic sheet extruders according to your specific raw materials and shape, we will offer the optimum solution.

Request for a quote

TECHNIC MACHINES

Turkey

We produce our triplex extruder machines for different plastic extrusion solutions. Such as with different extrusion screw design, screw length and diameter range according to final product of our customers and requested capacity. Our triple screw extrusion machine can work with different raw material such as PVC, PP, PE, TPO, TPE, TPU, EVA, PET, PS, WPC, ABS, HDPE, PC, TPR, PEX, PA, etc. We provide for our customers the optimum solutions according to their final product, raw material and capacity demand.

Request for a quote

TECHNIC MACHINES

Turkey

Our rattan extruder machines have different production capacity range and also capable to produce different rattan sizes, so that we can match different demand. You can produce with our rattan extruders different final product such as furniture and decoration etc. Plastic rattan raw material is mostly PE. PE has the highest stability if you compare with other plastic rattan raw materials alternative. Other most common raw materials for plastic rattan extrusion are PVC and PU. Where you can use plastic rattan ? - Rattan Chair - Rattan Table - Rattan Sofa - Rattan Coffee Table - Rattan Bench Just contact with us for your rattan extrusion machine research, we will provide the optimum solution for your research.

Request for a quote

TECHNIC MACHINES

Turkey

We offer our Plastic Extruder Machine Lines for various industries, including construction, food, healthcare, white appliances, and automotive sectors. The most common raw materials used on our plastic extrusion machine lines include PVC, HDPE, PET, EPDM, PP, EPS, LDPE, PE, ABS, PC, PS, and others. We provide as standard Plastic Extruder Machine Lines WPC Extrusion Machine Strap Extrusion Machine Sheet Extruder Machine Rattan Extrusion Machine Polystyrene Extruder Machine Polycarbonate Extruder Machine Edge Band Extrusion Line Gasket Sealing Extrusion Machine As Technic Machines, we offer our customers optimal solutions for their specific needs in plastic extruder machine research. We provide custom solutions using twin screw extruders, single screw extruders, triplex extruders, or co-extruders. Our specialized extrusion line solutions are tailored to the final product requirements of our customers.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

TECHNIC MACHINES

Turkey

We have options for WPC extruder lines, we provide WPC extruder machines with different capacity and different WPC final product as to our customers request. We offer WPC extruder machines for different product options. For example WPC decking extruder, WPC board production line, WPC profile extruder machine, WPC foam board production line, WPC flooring extruder machine and for other WPC extruder machines. Popular WPC Products - WPC Flooring - WPC Foam Board - WPC Board Panel - WPC Profile - WPC Decking Just contact with us for your WPC extruder machine research, we will provide the optimum solution.

Request for a quote

RHIMEX.COM

Netherlands

Rhimex supplies over 5000 rubber profiles from stock in factories in the EU. Glued or vulcanized corners, inflation profiles, and profiles in different colors are just a few of the many possibilities. If the rubber profile you are looking for is not available in our wide range, we can have it custom made for you, in specific lengths or, for example, in frames. For €95 we will make a tool for you for exactly the rubber profile you need. The possibilities are endless! Feel free to contact us, we are happy to help you! WWW.RHIMEX.COM #constructie #bouw #future #toekomstbestendig #maatwerk #industrie #industry4_0 #energietransitie #energytransition

Request for a quote

RHIMEX.COM

Netherlands

RENOVATION SEALS FOR WINDOWS AND DOORS Brush seals - Window seals - Sash rebate seals - Edge protection seals - Adhesive seals - Foam rubber seals - Steel frame seals - Door seals - U-profiles More than 2.000 profiles from EU stock. New tooling starting at EUR 95.- Delivery time 2/4 weeks. Several standard colours available. From 35 / 85 shore

Request for a quote

JUNTA POLYMERS

Belgium

Rubber and Silicone extrusion following your samples or technical drawing in EPDM, Silicone or other qualities.

Request for a quote

FLEXPLAS

Turkey

Crafted for your profile in a perfect way Flexplas designs and manufactures turn-key extrusion lines for the manufacture of flexible tape and profile. We build all the machines and tooling systems that are necessary for production. Flexplas profile extrusion line boasts the latest technology enabling optimum performance at the highest line speeds. The whole extrusion system is controlled via a single master control panel including a large touchscreen PLC. With our complete equipment you can produce a wide range of hose diameters extending from small to larger, according to your need. Features: *High-speed extrusion line for the best quality profile and tape *Production of sizes as per customer need *Customized design to meet customer requirements *Master control panel with Smart PLC system with color touch screen. *Remote control of the complete line with one master control panel. *Downstream equipment can be separated and installed to another production line when necessary.

Request for a quote

GNEUSS KUNSTSTOFFTECHNIK GMBH

Germany

The Gneuss Processing Unit (GPU) is a modular configuration of different Gneuss products and technologies, which are combined in to a high performance extrusion line for the manufacturing of high quality products.

Request for a quote

BOSCH MANUFACTURING AND SERVICES BELGIUM

Belgium

we can safeguard a very high level of process control in our extrusion production lines because our vulcanization process is done in a salt bath. This means the temperature of vulcanization is stable and independent of external conditions. This way, we can produce rubber profiles of a very consistent and high quality. Co-extrusion: we can produce 2 rubber types (eg hard and soft) into 1 final product High geometrical accuracy High surface quality Can be tailored to customers' needs Possibility to apply different types of coatings (our patented PPC coating, graphite coating or chlorinated).

Request for a quote

WUXI KAIJINHUA PLASTIC INDUSTRY CO.,LTD

Belgium

ideal for production of car footmat and trunk mat, backing width and weight adjustable.

Request for a quote

FLEXPLAS

Turkey

Flexplas designs and manufactures turnkey extrusion lines for flexible PVC hoses reinforced with a spring steel wire and PVC coated spring steel wire helix. That is, we build all the machines and tooling systems that are necessary to produce “PVC-steel wire hose”. We realize this with our technological know-how and perfected craftsmanship. With our complete equipment you can produce a wide range of hose diameters extending from small to larger, according to your need. The complete line is automated, equipped with modern production management systems, and constructed as energy-efficient which includes the use of energy-efficient motors of the latest generation and LED lighting concepts. Furthermore, the machine has been designed to ensure a safe, easy, and time-saving operation after an accidental power failure or emergency stop. This also applies to relevant data items.

Request for a quote

FLEXPLAS

Turkey

FLEXPLAS DRIVEN CONVEYORS are designed to your specifications and adapted to your specific extrusion line and manufacturing requirements for maximum efficiency Flexplas take-away conveyors are designed with tilt/dump tables to be used when cutting flexible hoses and tubing. Typically located directly after cutting devices, Driven Conveyors enhance the cut length tolerance and cut quality by supporting and transporting the hose away from the cutter bushing at adjustable speeds typically more than line speed, eliminating accumulation and sorting confusion. The hose can then be optionally ejected by a pneumatic ejector system into a collection tray for operator removal or for coiling by a winding machine. The driven conveyor automatically discharges parts to a collection tray for this purpose. Our conveyors can be optionally configured for one side or dual side collection which is for double extrusion of the hose on the same extrusion line.

Request for a quoteResults for

Templates for plastics extrusion - Import exportNumber of results

28 ProductsCompany type