- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- technical moulding

Results for

Technical moulding - Import export

SPANSET SECUTEX GMBH

Germany

Worm screws, gear wheels, slide rails and other technical mouldings are today made of engineering plastics such as POM (polyoxymethylene), PA (polyamide) or PE (polyethylene). These materials with different property profiles (negative high water absorption with PA, poorer wear behaviour with PE) are supplied as sheets or rods. The required moulded parts are then produced by mechanical processing (turning, milling etc.) in a more or less complex manner. Effective injection moulding is only worthwhile for large quantities together with small component sizes, otherwise the high tool costs cannot be amortized. secutexTechno is characterised by high hardness (70° Shore D) and rigidity over a wide temperature range. It retains its high toughness down to 30 °C, has a high abrasion resistance and a low coefficient of friction. The intrinsic colour is yellow, making it well suited for technical applications. Mechanical processing is simple and comparable with other hard plastics.

Request for a quote

ALWA TECHNISCHE PRODUKTE FÜR KUNSTSTOFFVERARBEITUNG, MODELL UND FORMBAU GMBH

Germany

ALWA MOULD P is a cold curing casting resin for the production of porous moulds, slabs and blocks for the ceramic industry. It is a porous and high-strength plastic, which is well-suited for high pressure casting applications. ALWA MOULD P can be used in various areas of the tableware and sanitary ceramics, technical ceramics, plastic mould procedure as well as various filtration processes. The high stability and defined porosity of the material allows highly accurate mould surface reproductions. With ALWA MOULD P various geometric moulds for filtration processes of suspensions can be produced. ALWA MOULD P can be used for ceramic slip pressure casting procedures. In this procedure, water is removed by a filtration process of a clay suspension (slip), so that an increasing clay layer is built on the mould wall over time. The moulds, slabs and blocks of ALWA MOULD P are easily machinable (e.g., drilling, milling).

Request for a quote

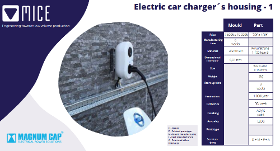

MICE - MOLDS AND INJECTED COMPONENTS ENGINEERING

Portugal

Housings for machinery Bumpers Covers for trucks, cars

Request for a quote

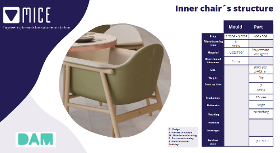

MICE - MOLDS AND INJECTED COMPONENTS ENGINEERING

Portugal

Housings for Equipments Sport Housing for Medical applications

Request for a quote

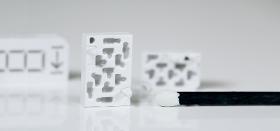

MICE - MOLDS AND INJECTED COMPONENTS ENGINEERING

Portugal

Design free structures

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

NINGBO FRIMA INDUSTRY CO. LTD.

China

Specifications: Product name: precision machining parts Material: aluminum, steel, brass ,plastic, carbon steel, nylon, PP Dimensions: according to customer’s drawing Surface treatment: Heat treatment, polishing, PVD/CVD coating, galvanized, electroplating, spraying, and painting etc. Packing: PE bag, carton, wooden box Processing equipments: cnc machining center, cnc lathe, grinding machine, automatic lathe machine, conventional lathe machine, milling machine, drilling machine, EDM, wire-cutting machine, CNC bending machine etc. Service project: To provide production design, production and technical service, mould development and processing, etc. Testing machine: Digital Height Gauge, caliper, Coordinate measuring machine, projection machine, roughness tester, hardness tester and so on. Minimum order quantity: 1000pcs Delivery: 7-30 days Business scope: CNC center machining, drilling, turning, grinding, tapping, mould design and processing, casting, sheet mental working etc.

Request for a quote

NINGBO FRIMA INDUSTRY CO. LTD.

China

Material: aluminum, steel, brass ,plastic, carbon steel, nylon, PP Dimensions: according to customer’s drawing Surface treatment: Heat treatment, polishing, PVD/CVD coating, galvanized, electroplating, spraying, and painting etc. Packing: PE bag, carton, wooden box Processing equipments: cnc machining center, cnc lathe, grinding machine, automatic lathe machine, conventional lathe machine, milling machine, drilling machine, EDM, wire-cutting machine, CNC bending machine etc. Service project: To provide production design, production and technical service, mould development and processing, etc. Testing machine: Digital Height Gauge, caliper, Coordinate measuring machine, projection machine, roughness tester, hardness tester and so on.

Request for a quote

FATRA A.S.

Czech Rep.

NOVOPLAST – plasticized PVC The title NOVOPLAST ® indicates plasticized PVC granulates. It is a mixture of various additives combined suitably according to its further use. The most important additives to plasticized mixtures may in addition to PVC and plasticizers include thermal stabilisers, lubricants, separation agents, filling agents, pigments, flame retardants, light stabilisers, antioxidants, various modifiers, etc. The content of plasticizer in the mixture is determined by final hardness of the mixture. Hardness of resulting mixtures ranges from 45 degrees on the Shore A scale to the hardest Novoplast – 60 degrees on the Shore D scale. Novoplast granulates are processed subsequently using mainly extrusion, injection moulding, and mould pressing technologies. Final products manufactured from plasticized NOVOPLAST® granulates are various types of hoses, hoses with special resistance against gasoline, diesel, oil, frost, etc., technical mouldings, floor covers, outsoles,...

Request for a quote

PHILPLAST LTD.

Bulgaria

Philplast can produce a wide variety of plastic items using the technologies of injection molding: - Technical articles - Caps - Various plastic elements Our products have numerous applications in multiple areas of production such as: home appliances, automotive, electronics, cosmetics, detergents, etc. In the creation of injection-molded articles we use a wide variety of plastic materials: ABS, PA, PC, PS, POM, TPV, TPE, PP, PE, as well as reinforced plastics (glass or mineral filled) . All materials are sourced from established and reliable suppliers from Germany, Italy, Bulgaria and Great Britain. The size of our injection-molded articles can weigh up to 1000gr with a clamping force of the machine from 50 to 200 tons.

Request for a quote

KUNSTSTOFFTECHNIK SCHMID GMBH & CO. KG

Germany

Customers from a wide range of industries rely on technically sophisticated injection-moulded parts made with up to three components. Our unique strength lies in the areas of multi-component technology, thermoplastics processing, elastomers and high-performance plastics.

Request for a quoteResults for

Technical moulding - Import exportNumber of results

11 ProductsCompany type