- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- welding systems

Results for

Welding systems - Import export

UNITED PROARC CORPORATION

Taiwan R.O.C.

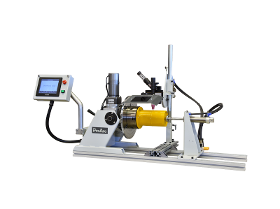

ProArc PCW Precision Circumferential Welder provide all of the features necessary to position and rotate parts for circumferential welding. Advantage: 1. The extreme accuracy welding lathe with servo motor control for turntable and transverse carriage. 2. Allow unskilled people to get high welding quality and consistently production progress. 3. Designed to enable horizontal or vertical configuration for more flexible welding solution. 4. ProArc offers a user-friendly and intuitive controller interface that allows users to implement the system quickly. 5. ProArc designed AVC (option) Enable to set the parameter of AVC in the integrated controller. 6. Motorize carriage on X axis (option) Ball screw drive system with dual linear guide way. * Positioning accuracy is +- 0.01mm * Travel speed 1 ~ 10,000 mm/min 5. Maximum through hole for diameter 80mm. *CE Conformity

Request for a quote

UNITED PROARC CORPORATION

Taiwan R.O.C.

4 Major Advantage: 1. Cost effective and modular design.to increase welding productivity. 2. Set up with CB-107-1 Sequence controller : * User-friendly sequence controller. * Save 100 sets of programs * Even a non-experienced user can learn how to operate in few minutes. 3. High frequency protected 4. Suitable for different welding processes like TIG, MIG and plasma welding. 5. 2 year warranty *CE Conformity

Request for a quote

UNITED PROARC CORPORATION

Taiwan R.O.C.

ProArc ServoArc PT-200s is ready for sell. It is a mini positioner that specially designed for automated welding. PT-200s adopts with servo motor and multi-functional CB-500 controller to provide the most stable rotation. It’s easy to build your own welding parameter library that significantly improves welding quality and increases production yield in a short time. • Excellent graphic user interface controller • Uses 20-bit servo motor to achieve 0.1° rotation accuracy • Speed of 0.01 ~ 30 rpm with constant torque & rotation stability • Tilting range from 0 ~ 120°, manual adjustment • Floor type structure for convenient loading/unloading of weldments - create welding flexibility • High frequency interference protection • Spindle through hole allows delivery of shield gas

Request for a quote

UNITED PROARC CORPORATION

Taiwan R.O.C.

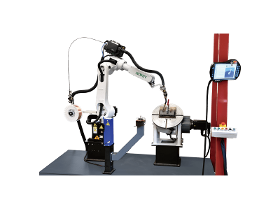

ProArc and HIWIN bring robot application to a intelligent and remarkable milestone in welding industry through the new weld robot system. System comes with full package including Cut wire Work station w/Multi Task Modular cells To define robot in the COORD export system Pass [Position Register] function to make function infinity

Request for a quote

UNITED PROARC CORPORATION

Taiwan R.O.C.

ServoArc welding package can be simply applied in ProArc standard welding product by changing servo motor and integrate with advanced control box CB 500 or CB 600. 4 major advantages you will get 1. Equipped with servo motor 2. Welding program can be edited and stored 3. 0~10V analog interface available to control welding current 4. 3 additional dry contacts available for accessories such as Cold Wire Feeder, Arc Voltage control, Welding Oscillator etc.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

UNITED PROARC CORPORATION

Taiwan R.O.C.

ProArc helps our customer to develop the laser welding automation system in Golf clubs manufacturing industry. Integrated with Fanuc robot system and Rofin laser, we provide a total solution for our customer both in laser welding and laser cutting. Industry 4.0 Intelligent manufacturing Full automation production Custom design for automotive industry

Request for a quote

UNITED PROARC CORPORATION

Taiwan R.O.C.

ProArc E.Z.Arc Welding System ProArc Smart controller CB-107 EWM PITOMIG

Request for a quote

UNITED PROARC CORPORATION

Taiwan R.O.C.

1. ProArc manipulators are heavy duty and precise automatic welding systems. It can support both circumferential and longitudinal welding application from small tube to big tank. 2. The stroke of column and boom is available from 2m x 2m to 7m x 7m. 3. ProArc manipulators are heavy duty, precise automatic welding systems. They are designed for circumferential or longitudinal welds of great length. 4. All manipulators are available as bolt-down or free standing base, and heavy duty table bearing mount for column rotation or be mounted on to travel car. 5. All ProArc manipulators have anti-fallen device. 6. Controls include up/down, right/left travel switch speed potentiometer and high rapid travel.

Request for a quote

UNITED PROARC CORPORATION

Taiwan R.O.C.

The ProArc WO-15 oscillator is perfect for automated arc manipulation by use of mechanical arc oscillation. It's suitable for MIG/MAG automate processes in heavy fabrication industries. There are four adjustable parameters (oscillation width, oscillation speed, oscillation dwell time on both ends) which controlled by simple control panel. ProArc WO-15 oscillator can work as stand-alone device or be a part of more advanced welding system.

Request for a quote

UNITED PROARC CORPORATION

Taiwan R.O.C.

ProArc manipulators are heavy duty and precise automatic welding systems. It can support both circumferential and longitudinal welding application from small tube to big tank. Our welding manipulator has maximized both safety and productivity. The stroke of column and boom is available from 2m x 2m to 7m x 7m. All welding manipulators (Column and boom) can work on different welding process. Special design manipulators are available at request.

Request for a quoteResults for

Welding systems - Import exportNumber of results

11 ProductsCountries

Company type