- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- tablet press

Results for

Tablet press - Import export

MESUTRONIC GMBH

Germany

METAL SEPARATOR FOR THE PHARMACEUTICAL INDUSTRY FOR THE INSPECTION OF TABLETS AND CAPSULES. Detects and separates all metals encapsulated or as loose parts. Meets the highest h ygiene requirements. Fast decontamination of all product touching parts without tools. Fits every tablet press and deduster installation. High throughput owing to round equipment design DN50.

Request for a quote

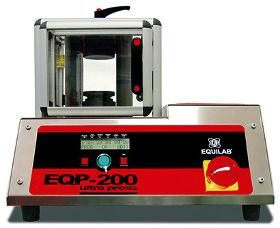

EQUILAB

Spain

The EQP-200 Pellet Press has been especially designed to obtain high quality pellets/tablets for XRF. This press can exert a pressure of up to 40 tons. Of durable and robust design, it is very easy to manage, efficient, and offers 5 working programs with single and double pressing cycles. An exceptional instrument. Keeping all the features of its predecessor (EQP-100), the EQP-200 also offers the possibility of making pellets of different diameters, just by changing the pressing tool. This device facilitates also the cleaning and maintenance tasks. Its versatility enables the unit to work also with different shapes of press tools, such as square, rectangular, etc.

Request for a quote

ROYAL FOREST

Russia

Natural chlorella powder pressed in sguare tablets

Request for a quote

ECOPEATMIX

Russia

Pressed peat moss tablets Ø 32 mm is manufactured for growing seedlings of various flowery and decorative cultures under domestic conditions, on plots of land attached to a house, in the open and protected soil. Tablet features: Pressed peat moss tablets Ø 32 mm are produced from high-moor milled peat dried to 27-29% moisture and pressed into the round form for pots with a volume 0.3 liter. Content of nutritious elements (mg/100g of dry substance): Nitrogen (ammonia and nitrate) 100 - 120 mg Phosphorus 150 – 200 mg Potassium 150 – 200 Trace substances: Cu, B, Mn, Mo, Zn, Fe Electroconductivity 0.5 – 1.1 mS/cm Tablet dimensions: 0.3 L – Ø 32 mm, height 7-9 mm, weight 7-8 g.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

MÜLLER GMBH

Germany

3.3 Machine hoppers Feed hoppers for a wide variety of production lines, such as tube filling lines, size reduction equipment, tablet presses, etc. Just send us a sketch of your system, and we will make you a quotation for your duty Telefon: +49 (0) 76 23 / 9 69 - 0 Fax: +49 (0) 76 23 / 9 69 - 69

Request for a quote

MÜLLER GMBH

Germany

All our drum lifters do not only handle your drums safely, they also meet GMP-standards. All lifting, inverting and swiveling columns work with electric motors which is very low noise level and operator friendly. For all different types of drums we can offer drum lifters with suitable pick up systems. The slim but stable mast offers the operator a safe visibility to the load. You can manage all handling operations like feeding of tablet presses, capsule filling machines, blister packaging machines, sieves or other transferring tasks with a Müller drum lifter. The lifting operation is always done by electric motor, all other operations like clamping, inverting and swiveling can be done either manually or by electric motors. Drum lifters from Müller are known for economic, save and ergonomic drum handling. Drum lifters with universal clamp lift / swivel / invert column Type FTHSK 300 G2 loads up to 300 kg column height 3.6 m Design: motorized lift manual grip, invert and swivel...

Request for a quoteMÜLLER GMBH

Germany

The filling of drums and the transfer of their contents are special situations, since each time the product comes into contact with the environment. We manufacture stainless steel hoppers for different industrial processes. Symmetric and asymmetric hoppers with shut-off butterfly valves in nominal diameters up to 300 mm make the complete operation dust-free and waste-free, and are not restricted only to Müller drums. Various cones and discharge aids, from rotary hooks to pneumatic vibrators, contribute to a problem-free emptying process.And the beauty of it is that the stainless steel hopper is only fitted when and where it is needed. This saves space and is highly cost-effective. 3.0 Info Stainless steel hoppers Hoppers (modules to fit lidded drums) Size: To fit all Müller drums, available in Ø 120 mm to Ø 1200 mm Application: Filling, emptying, mixing, charging reactors, feeding production lines and tablet presses Product: Powders, liquids Shape: The right angle for your...

Request for a quoteResults for

Tablet press - Import exportNumber of results

9 ProductsCountries

Company type