- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- special seals

Results for

Special seals - Import export

KASAG SWISS AG

Switzerland

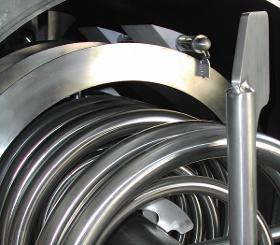

In order to prepare the fruit base, vegetables, jam, marmalade, jelly and sauces, horizontal or vertical mixing systems are used. Mixers are vital for attaining the highest product quality. The main aim is to ensure consistent mixing and temperature distribution by applying the lowest possible shear force on the pieces of the product. Since it is possible to thereby realise short process times along with the qualitatively high-value process apparatuses, KASAG has the ideal mixing technology for you. For the horizontal mixers, KASAG also has a special bearing and mechanical seal that has been tried and tested over many years. On an ongoing process to develop our mixing system and the bearing and mechanical seals further to attain optimal product quality and to enable smooth operation.

Request for a quote

ZEPTER INTERNATIONAL

Switzerland

Compact design and easy-to-use automatic vacuum packing function make the VacSy® bag Sealing Unit ideal for preserving a variety of foods. The supplied adaptor turns the sealing unit into a vacuum pump, and makes it compatible with VacSy® containers, universal lids and bottle caps. The built-in liquid sensors prevent the liquid from penetrating the device when vacuuming foods high in moisture, while its integrated overheating sensor and low energy consumption make it safe and economical to use. Presentation SEAL SHELF-LIFE & FRESHNESS FIVE TIMES LONGER Advanced technology, top quality materials, and modern design make the VacSy® Sealing Unit superior to anything else in its class. This pioneering system removes air and moisture from specially-designed durable bags while sealing in flavour.

Request for a quote

KASAG SWISS AG

Switzerland

KASAG experts are specialists in the construction of kettles, industrial cooking plants for the production of fruit base, vegetables and sauces. Its comprehensive systems that include cookers, coolers, condensers, piping and valves are being built according to current requirements in aseptic design. Preventing product contamination caused by germs in the products is a central concern. This is enabled through optimized equipment design, special bearing and mechanical seals and a functional CIP(Cleaning in Place) facility. We adapt to the needs of each and every new customer and seek to build customized or modular plants that fulfil their requirements to the maximum extent.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

Results for

Special seals - Import exportNumber of results

3 ProductsCompany type