- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- processing equipment

Results for

Processing equipment - Import export

BÜCHI AG

Switzerland

Glass-lined steel reactor: 250 - 10'000 liter Pressure: -1.0 (FV) to +0.5 bar Temperature: -60 °C (-90 °C) to +200 °C Material: Borosilicate glass 3.3, glass-lined steel, PTFE, PFA, tantalum Chemical process equipment consisting of glass-lined reactors or mixing tanks with distillation overhead in borosilicate glass can be operated at full vacuum and low pressure. A large variety of chemicals can be processed in such plants due to the highly corrosion resistant materials used. The design varies between multipurpose product / process specific set ups. Feeders and receivers are made of glass for smaller units and of glass lined steel for larger setups. Shell and tube type heat exchangers are built with inner tubes made of borosilicate glass, glass-lined steel, silicon carbide, tantalum or other metals depending on process parameters and other requirements.

Request for a quote

MTA ROBOTICS AG

Switzerland

MRC500 soldering platform for robotic soldering from above is a free-standing machine cell. Our design engineers purposes-built the MRC500 for soldering applications then standardized the design. We purpose-built our own platform so we would not need to compromise functionality based on the limitations of third-party equipment. Standardizing the design offers three primary advantages. It is well-proven, available faster, and costs less than-off custom designs. Although the design is standard, it is highly flexible. We designed the mechanical structure to work with a wide range of process equipment, material handling, and guarding systems. In its basic configuration, the MRC500 is a free-standing, semi-automated machine. At the other extreme, we can outfit it with SMEMA conveyors, collaborative robots, turntables, and many other systems.

Request for a quoteLIST TECHNOLOGY AG

Switzerland

The LIST KneaderReactor Technology fills the gab and successfully combines the benefits of conventional process equipment, e.g.… Extruder Thin-Film Reactor Continuous Stirred-Tank Reactor (CSTR) Rotary Disc Reactor …with many other process characteristics which are unique for LIST. It provides an exceptional toolbox for developing new innovative and economical products and processes helping our customers to stay up to date with process technology. Your benefits Effective self-cleaning to minimize dead zones, product accumulation and product degradation Excellent kneading and mixing for better homogenization Effective heat transfer High surface renewal efficiency Large free vapour volume Precise and uniform temperature control due to large heat transfer areas Continuous or batch processing Process intensification Processing of sticky and highly viscous products Residence time is independent from agitator speed Wide and flexible range of average residence times Wide turndown...

Request for a quote

BÜCHI AG

Switzerland

Glass distillation columns up to DN 600 are packed with random packing such as Raschig rings, ceramic saddles, PFA packing elements or structured packing dependent on the required separation performance and process media. Each packing type shows different separation performance, indicated by their number of theoretical stages. In combination with glass process equipment, highly corrosion resistant packing material is used for packed glass distillation columns.

Request for a quote

ENDRESS+HAUSER AG

Switzerland

Memosens amperometric oxygen sensor for standard, hygienic and sterile applicationsThe Oxymax COS22D safeguards your products, process and plant equipment from oxygen influences. It measures reliably over a wide range helping you to better monitor and control your applications. The sensor is low-maintenance and ensures long-term stability - even with frequent sterilization and autoclaving. Thanks to Memosens digital technology, COS22D combines maximum process and data integrity with simple operation. It enables lab calibration and facilitates predictive maintenance.

Request for a quote

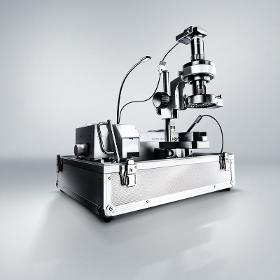

KOMAX HOLDING AG

Switzerland

The MicroLab 10 enables micrographs to be taken quickly and easily regardless of the location. It covers all relevant processing steps – from cutting and polishing to etching and visualization. The compact carry-case design enables the quality of crimp and splice connections to be assessed with minimum effort and maximum effectiveness. Available in a portable carry-case, the compact MicroLab 10 is designed for contacts and conductors of up to 2.5 mm in diameter. The samples can be quickly clamped in the holder – no re-clamping for all processing steps. The laboratory’s components include autonomous, independent preparation, evaluation and documentation modules. A complete on-site analysis can therefore be performed within a short period of time. A USB digital camera with a microscope is integrated into the lab for visualization purposes and to ensure complete documentation.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

Results for

Processing equipment - Import exportNumber of results

6 ProductsCountries

Company type