- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- process development

Results for

Process development - Import export

KASAG SWISS AG

Switzerland

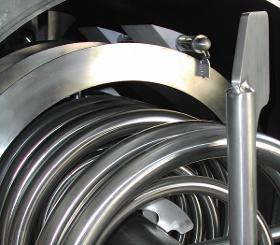

In order to prepare the fruit base, vegetables, jam, marmalade, jelly and sauces, horizontal or vertical mixing systems are used. Mixers are vital for attaining the highest product quality. The main aim is to ensure consistent mixing and temperature distribution by applying the lowest possible shear force on the pieces of the product. Since it is possible to thereby realise short process times along with the qualitatively high-value process apparatuses, KASAG has the ideal mixing technology for you. For the horizontal mixers, KASAG also has a special bearing and mechanical seal that has been tried and tested over many years. On an ongoing process to develop our mixing system and the bearing and mechanical seals further to attain optimal product quality and to enable smooth operation.

Request for a quote

BÜCHI AG

Switzerland

Glass reactor: 20 to 30 liter Pressure: -1.0 (FV) to +0.5 bar Temperature: -60 °C (optional -90 °C) to +200 °C Material: Borosilicate glass 3.3, PTFE, PFA, PEEK The midiPilot is our sturdy multipurpose glass reactor for small volumes. It is specifically designed for applications in kilo lab, for chemical process development and cGMP compliant API syntheses. A clean-room setup and other materials are available to meet your specific process requirements. A clean-room setup and other materials are available to meet your specific process requirements.

Request for a quote

BÜCHI AG

Switzerland

Customized parallel pressure reactor system Reactor volume: 50 ml - 300 ml Number of reactors: 2 - 6 Pressure: -1.0 (FV) to +150 bar Temperature: -20 °C to +300 °C Material: stainless-steel, Hastelloy®, tantalum, PTFE inliner Other setups are available. Catalyst screening and Hydrogenations in reduced time, reproducible and safe: These were the key issues for our customer in chemical research, asking us to develop this system. This parallel pressure reactor system is configurable and modular, allowing for individual or parallel operation settings of each reactor. This system uses automated process control enabling fast process development and parallel reaction screening in a reproducible and safe manner. Multiple safety features guarantee safe hydrogenations and other processes.

Request for a quote

BÜCHI AG

Switzerland

With the miniPilot product family (reactor, nutsche filter, scrubber) we offer miniplant pilot reactors for chemical process development, scale-up, process simulation and kilo-scale production. The reactors' explosion proof design (ATEX) and inert materials allow safe processing of solvents and acids in a completely sealed reaction vessel. The compact standard reactor setup can easily be modified, interchangeable reaction vessels of 5, 10 and 15 liter including interchangeable stirrers are available. The reaction vessel is installed on a lifting / lowering device to simplify opening and cleaning. The distillation glass overhead is built with flexible ball-socket joints for multiple chemical reactions under full vacuum. A clean-room setup and other materials are available to meet your specific process requirements.

Request for a quote

ENDRESS+HAUSER AG

Switzerland

The new Liquiphant FTL51 is specialized for the process industry and already developed according to IEC 61508 to be used directly in SIL2 and SIL3 applications without big efforts. You conduct periodic proof tests according to SIL or WHG simply mobile with an intuitive wizard. At the end you receive an automated documentation., Liquiphant measures reliably and is not affected by changing media properties, flow, turbulences, gas bubbles, foam, vibrations or build-up.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

TSE TROLLER AG

Switzerland

The critical point in the case of newly developed production processes is the adaptation of the test scale on the production scale. The R&D facilities of TSE Troller offer certainty: Exact predictions for the interpretation of the future production process are just as possible as the cost saving elimination of error sources. The easiest way for further development of your products. We offer our customers individual solutions according to their challenges. Please do not hesitate to contact us for further information.

Request for a quoteResults for

Process development - Import exportNumber of results

7 ProductsCountries

Company type