- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- pneumatic

Results for

Pneumatic - Import export

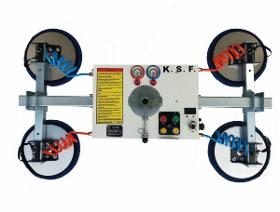

KEM TECH

Switzerland

It is an autonomous device thanks to its battery power supply and with its supplied equipment it is also a versatile load lifter for construction site or workshop.

Request for a quote

KEM TECH

Switzerland

The EV-300 electro-pneumatic lifting beam is an autonomous device intended for handling any glass on site or workshop.

Request for a quote

PROMIX SOLUTIONS AG

Switzerland

Promix supplies key components to optimize the production of light foams such as XPS insulation boards, XPET construction boards, XPE foam films, etc. Thanks to the improved cell structure, the foam density can be further reduced, and the throughput of the plant increased, resulting in significant cost savings in production. Replacement of iso-butane for the sake of the environment Iso-butane and other hydrocarbons are excellent blowing agents for high expansion foam production.However, they are also highly harmful to the environment and highly flammable, which increases the production risk. Promix gas dosing stations in combination with other retrofittable process engineering components enable at least a partial switch to the non-flammable and environmentally neutral gases CO2 and nitrogen. Your optimization potential ,Improved mechanical product properties ,Lower foam density ,Replacement of hydrocarbon blowing agents with CO2 and nitrogen ,Increased line throughput

Request for a quote

PROMIX SOLUTIONS AG

Switzerland

Monitor the quality in your extrusion line, fiber production, polymer production or food and chemical production continuously in real time with the Promix Visco-P inline viscosity meter. Prevent scrap production and reduce raw material costs through active raw material management. Promix Visco-P is a true online rheometer that helps you monitor your production process and save production costs. Ask for a test unit and see for yourself! Advantages Promix Visco-P inline viscosity measurement ,Continuous monitoring of raw material quality and process conditions in real time ,Raw material cost reduction through active raw material management ,Precise inline viscosity measurement in the melt stream – without bypass ,Suitable for all viscous media ,Additional benefit of melt and temperature homogenization in the Promix melt blender, which also serves as a measuring section ,Can be integrated into any extrusion line ,Test units available

Request for a quote

PROMIX SOLUTIONS AG

Switzerland

Insufficient surface quality, long cooling times, uneven thickness tolerances or other quality problems often limit maximum production output. Promix melt blenders eliminate these limitations sustainably and lead to significant cost savings. Would you like to optimize your extrusion process? Improved melt homogeneity and a more uniform melt temperature create tighter thickness tolerances and better surface quality. And quite often, it can also increase production throughput. Promix offers you highly effective static mixers and melt blenders at low investment costs. They are supplied ready for installation, including heater bands and holes for pressure and temperature sensors. The melt blenders are usually installed downstream of the screen changer & gear pump, and upstream of the die. The very short installation length allows easy retrofitting in existing extrusion lines.

Request for a quote

PROMIX SOLUTIONS AG

Switzerland

Mixing nozzles and static mixers from Promix ensure excellent melt homogeneity and efficiently prevent color streaks or flow lines. Quality problems in injection molding are often solved by modifying the process parameters. Masterbatch concentration and back pressure must be increased, which makes production costs more expensive. This does not have to be the case! Mixing Nozzles from Promix ensure excellent melt homogeneity. Color streaks or irregularly distributed additives in the component are a thing of the past. The ready-to-connect mixing nozzle is installed on the injection molding machine replacing the standard nozzle. Contact us for a mixing nozzle to test.

Request for a quote

PROMIX SOLUTIONS AG

Switzerland

Promix specializes in demanding cooling and heat exchanger tasks such as cooling and heating of viscous or decomposition-sensitive media / plastic melts. The Promix P1 heat exchanger is the unique combination of a very efficient static mixer and a powerful cooler. The novel patented technology opens up completely new process engineering possibilities in the cooling and heating of plastic melts and other viscous fluids. The simultaneous mixing and cooling processes in the P1 allow for very efficient cooling and heating without the formation of deposits or the risk of product decomposition. Advantages Promix P1 heat exchanger Very efficient cooling of polymer melts close to the solidification point Precise temperature control and uniform temperature distribution at the outlet Very robust construction Extremely gentle cooling and heating of residence time critical fluids Unique self-cleaning behavior Reliably scalable from laboratory test to production scale Test options

Request for a quote

PROMIX SOLUTIONS AG

Switzerland

The Procell nucleation additives developed by Promix are specially adapted to the Microcell foam extrusion of plastic melts. They lead to microcellular foam structures, a key factor for high mechanical strength of the foamed product. Homogeneous, very fine-cell foam structures are the key to high mechanical strength. Promix has developed specific Procell nucleation additives. These are specially adapted to the Promix Microcell foam technology and lead to microcellular foam structures. The additives can be used in foam extrusion and light foam extrusion for many polymers such as PP, PET, PE, PS, ABS, PLA and are suitable for food contact applications. Contact us for a test sample.

Request for a quote

PROMIX SOLUTIONS AG

Switzerland

Promix gas dosing stations for physical foaming have been specially designed and developed to meet the needs of foam extrusion. Promix gas metering technology is characterized by high dosing accuracy, reliability and amazingly simple operation. Promix gas dosing stations meet all the requirements of a modern gas metering system for foam extrusion. These include high-precision mass flow control, process visualization by means of trend charts, operator-definable operating limits, data acquisition, and synchronization of the dosing rate with the extruder output. Implementation in the extruder control system via fieldbus system is also possible. •,Mass flow from 1 g/h up to 20'000 g/h •,Dosing pressure up to 680 bar

Request for a quote

PROMIX SOLUTIONS AG

Switzerland

Microcell foam extrusion systems from Promix are used for a wide variety of applications and for almost all polymers. Thanks to the production of very homogeneous microcellular foam structures, high-quality foam products with very low densities and excellent mechanical properties can be produced. Physical foaming can reduce material consumption and thus costs by an average of 20%. This not only saves money but also has a positive impact on the environment. Promix Foam extrusion systems set standards in the production of microcellular foam products with very homogeneous cell structure and high process consistency. The systems operate with environmentally friendly blowing fluids nitrogen or CO2 and are easy to integrate into existing or new extrusion lines. Depending on the application, density reductions of 5 to over 70 % can be achieved.The technology can be used for packaging films, sheets, foam core and corrugated pipes as wellas profiles, cable sheating, blow molds and blown films.

Request for a quote

KELLER PRESSURE

Switzerland

This pneumatic hand pump can generate negative pressure/vacuum and pressures of up to 25 bar. Thanks to the integrated fine adjustment valve, any calibration pressure can be configured precisely and rapidly, making the pump ideally suited to testing measuring equipment. An additional manometer (not supplied) is needed for reference measurement of the configured pressure. KELLER recommends manometers in the LEX1 series with a suitable pressure range.

Request for a quote

KELLER PRESSURE

Switzerland

This high-pressure pump generates pressures of up to 700 bar with ease, with fine control for precise adjustment. It is perfect for testing manometers and pressure transmitters. The pump must be filled with 100 cm3 of hydraulic oil or water and can therefore fill up even relatively large dead volumes. An additional manometer (not supplied) is needed for reference measurement of the configured pressure. KELLER recommends manometers in the LEX1 series with a suitable pressure range.

Request for a quote

FINDEVA AG

Switzerland

Properties Quiet and efficient Rated frequency 1,130 – 3,400 vpm Force 12 – 2,740 N Continuously variable FAL can be used up to 85°C, VTL-155 up to 100°C, remaining VTLs up to 150°C Resistant to extreme environmental conditions Field of application For foodstuffs and pharmaceuticals, complies with FDA specifications (FAL only) Driving conveyor and discharge chutes Loosening or compacting of bulk materials Starting up of mechanical processes Filling facilities

Request for a quote

FINDEVA AG

Switzerland

Properties Quiet and efficient Rated frequency 1,800 – 9,300 vpm Force 32 – 6,150 N Continuously variable Can be used up to 85°C Resistant to extreme environmental conditions Field of application For foodstuffs and pharmaceuticals, complies with FDA specifications Driving conveyor and discharge chutes Loosening or compacting of bulk materials Starting up of mechanical processes Filling facilities

Request for a quote

FINDEVA AG

Switzerland

Properties Quiet and efficient Rated frequency 1,800 – 9,300 vpm Force 32 – 6,150 N Continuously variable Can be used up to 150°C Resistant to extreme environmental conditions Field of application Driving conveyor and discharge chutes Loosening or compacting of bulk materials Starting up of mechanical processes Filling facilities

Request for a quote

FINDEVA AG

Switzerland

Properties Lubrication-free Low noise level Strong vibration by means of high speed and eccentric working torques Rated frequency 14,000 – 37,000 rpm Centrifugal force 750 – 5,700 N Continuously variable Can be used up to 150°C Resistant to extreme environmental conditions Field of application For foodstuffs and pharmaceuticals, complies with FDA specification Emptying of bunkers Screen filters Vibrating tables Preventing adhesion in pipelines and silos Transporting of fine powders Moving of bulk materials

Request for a quote

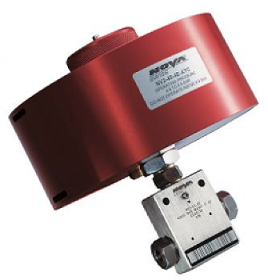

NOVA WERKE AG - NOVA SWISS

Switzerland

High-pressure systems can be automated easily and effectively by using Nova Swiss valves with air-operated actuators. The valve bodies and packing systems are identical to those in the manual valves and provide the same benefits. The extremely robust and reliable air-operated piston actuator is available in two versions: ATO (air-to-open), opens with compressed air. ATC (air-to-close), closes with compressed air.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

ELACTIS SA

Switzerland

DIN43650 TYPE A connector for solenoid valves and electromagnets. Features up to 90% power reduction, regulated current, detecting plunger movement, protection against surge currents, etc... Ideal for pneumatic, process and hydraulic valves. Custom set parameters for best efficiency. Can be used to enhance battery life, increase switching speed, allow higher pressure or flow ratings

Request for a quoteResults for

Pneumatic - Import exportNumber of results

19 ProductsCompany type