- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- parameters

Results for

Parameters - Import export

WIB SA

Switzerland

Cages are used to position and keep the balls distanced from each other at the pitch circle diameter. We offer a variety of different cage architecture and material tailor for each customer application. Cages are constructed of brass, steel, or synthetic materials. Brass and steel cages are manufactured at WIB. We also manufacturing our own tooling and can adapt cage designs to meet the requirements of the application. For certain applications, ball bearings without cages or full complemented bearings are manufactured.

Request for a quote

WIB SA

Switzerland

Packaging is a very important parameter for the retention of the bearing quality during transport and storage. It is designed to protect the bearings against corrosion, dust, and other pollutants. Apart from that, each unit is labeled and carries all the relevant information concerning the technical and quality features of the bearing. The production batch number is printed on the label and guarantees the traceability of the product, as well as the identification of the manufacturing date. Therefore, it is advisable to unpack the ball bearing only prior to use or assembly.

Request for a quote

WIB SA

Switzerland

The noise level is an important quality criteria of a ball bearing. It mainly depends on the following factors: precision of the geometric forms surface finish of the raceway and the balls cleanliness of the bearing type of lubricant type of cage rotational speed

Request for a quote

WIB SA

Switzerland

It is even possible to apply a coating on the outer ring, before assembling the bearing, thus guaranteeing the best possible geometrical forms. The machining of grooves ensures that the coating perfectly adheres to the metal surface. Additionally, a wider temperature range may be covered.

Request for a quote

WIB SA

Switzerland

By applying surface treatments on outer ring contact surfaces, it is possible to improve certain mechanical characteristics such as the hardness. By doing this, we can increase wear resistance while decreasing the friction coefficient. With certain treatments it is possible to achieve high resistance to specific chemical agents. The table below shows a small sample of examples of such surface treatments and their resulting technical characteristics.

Request for a quote

WIB SA

Switzerland

The resistance generated by the seal (if present), depending on the surface finish of the outside diameter of the inner ring, as well as of the rotational speed. The resistance generated by the cage, depending on the geometrical form and the machining quality of the cages. The resistance generated by the lubricant, depending on the lubricant viscosity and filling quantity as well as the rotational speed. At low speed and with fine instrument oil this resistance is insignificant. It will be higher at low temperatures and at high viscosity of the lubricant. Grease lubricated bearings will show, according to the grease type and filling, a much higher friction torque than oil lubricated bearings.

Request for a quote

WIB SA

Switzerland

The 100 Cr6 steel rings manufactured by WIB are stabilized after hardening by annealing. As a result of this treatment, they can be used at temperatures of up to 150°C. They have a hardness of 60 to 64 HRC For applications operating at high temperatures or in order to reduce their sensitivity to shock loads, it is necessary to stabilize the rings at higher temperatures after hardening. It should be noted that such a stabilization will slightly reduce the hardness of the rings.

Request for a quote

WIB SA

Switzerland

The radial clearance is not considered a quality criterion. An improper radial or axial clearance may have detrimental implications during operation within an application. This may include suboptimal noise levels, heat generation, rigidity, and fatigue life. Prior to recommending an internal clearance range, our applications will run an analytical simulation on the bearing and application to ensure optimal performance. For more complex system, our application engineers can complete a FEA analysis, particularly when evaluating multiple bearings within a non-rigid housing.

Request for a quote

WIB SA

Switzerland

The primary function of a lubricant is to lubricate the rolling and sliding contacts of a bearing to enhance its performance through the prevention of wear. This can be accomplished through various lubrication mechanisms such as hydrodynamic lubrication, electrohydrodynamic lubrication, and boundary lubrication.

Request for a quote

WIB SA

Switzerland

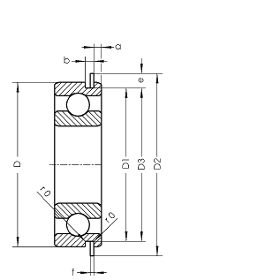

Certain applications call for special tolerancing to ensure optimal performance, which WIB is accustomed to accommodating. Dimensions that fall outside international standard will be identified with a PA designation, which appears in the descriptions and drawings. Special PA tolerances may be combined with standard tolerances when one or more tolerances are not referenced in the standards. These tolerances are shown on the bearing drawings as well. This is primarily used for bearings with profiles. For example: P0/PA

Request for a quote

WIB SA

Switzerland

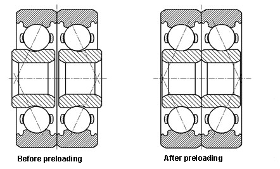

Pairing is achieved with bearings of identical tolerance classes and by applying an axial preload to the inner rings for the O arrangement and on the outer rings for the X arrangement. The inner or outer rings are undergo a separate grinding operation to align both side faces on the same plane with minimum clearance.

Request for a quote

WIB SA

Switzerland

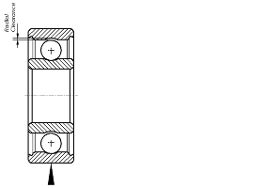

For certain applications, it may be appropriate to use ball bearings fitted with a snap ring fixed on the outer ring. The dimensions of the N groove and the snap ring R are are defined by the ISO 464 standard. The bearing is available in two versions, according to the customer’s requirements.

Request for a quote

WIB SA

Switzerland

Closures, more commonly known as shields and seals are used to protect the internal parts of the bearing against dust, liquid, and gaseous particle contamination. The shields help contain the lubricant in the bearing but are not designed to keep out liquid and gaseous contamination. We manufacture our own shields at WIB to the precise tolerance to minimize the opening gap, thereby offering great grease retention and longer life. On the other hand, seals are designed to keep various types of contamination out, keeping the grease clear of foreign particles and extending the bearing life.

Request for a quote

WIB SA

Switzerland

Each bearing is designed around the application it is used in and sometimes that include a profile on the inner or outer ring. We have an array of profiles that we can use on our bearings, including common ones listed below or something completely unique to your application. In collaboration with our application engineers, we will work with you to ensure the right profile, tolerances, material, surface finish, and even the harmonics of the profile are fine-tuned to ensure quite operation, even at high speeds.

Request for a quote

WIB SA

Switzerland

To ascertain proper mounting of the bearing on the shaft and housing while ensuring maximum surface contact area, the proper fillet radius must be used. Too small and the bearing will not sit flush against the shoulder, too large and we forego precious surface area to reinforce the support. Done right, the optimal surface area is used while avoiding any chance of interference between the fillet and the shaft or housing.

Request for a quote

WIB SA

Switzerland

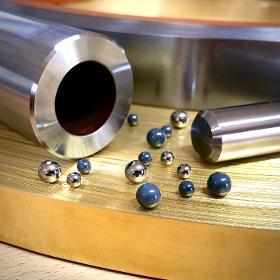

We offer a wide range of material depending on the needs of the application. When working with our application engineers, we will select the material type (and heat treatment method) to ensure the bearings meet the requirements of the application. This includes factors such as high wear resistance, heavy shock loads, extreme corrosion, as well as dimensional stability.

Request for a quote

WIB SA

Switzerland

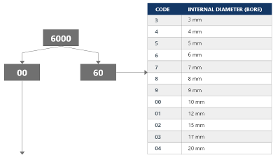

At WIB, we produce all subcomponents, including inner and outer rings, brass and steel cages, as well as the shields to the highest quality standards. Our Performance Bearings are manufactured to ISO, ABMA, DIN, and BS international standards while our Custom Bearings are tailored specific for each application. The Performance Bearing nomenclature is described below.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

KELLER PRESSURE

Switzerland

The DCX-22-CTD data loggers measure conductivity and temperature as well as pressure, along with the depth of bodies of water. The integrated Pt1000 achieves an accuracy of ±0,1 °C, and the conductivity can be measured at ± 2,5% of the selected range (0,2 / 2 / 20 / 200 mS/cm). Thanks to their long-life battery, they can keep recording measurement results for years (up to 10 years at a rate of one measurement per hour). The logger can be configured using the supplied software (measurement interval, incident management, delayed measurement start etc.) and data that has been read can be displayed in a graph or chart, corrected using air pressure values, converted into fill levels or other units, and exported.

Request for a quote

ENDRESS+HAUSER AG

Switzerland

1-/2-channel transmitter Liquiline CM442RCompact multiparameter DIN-rail and cabinet device for all industriesLiquiline CM442R is an easy-to-use, digital multiparameter transmitter for process monitoring and control in all applications - even where mounting space is limited. It saves you time and money through simplified and quick system integration, installation, and handling. The 1-/2-channel controller is extremely compact and fits in every cabinet. Liquiline CM442R provides you with all the benefits of a best-in-class transmitter platform from clever simplicity to maximum process safety.

Request for a quote

ENDRESS+HAUSER AG

Switzerland

Liquiline CM14 is a basic transmitter that offers all that you need to run a standard measuring point. It fits in the common cabinet cut-outs and is easy to commission thanks to Memosens digital technology. The Memosens hot plug and play concept allows you to quickly install and configure your digital pH/ORP, conductivity or dissolved oxygen sensors. Liquiline CM14 is compact, easy-to-operate, and cost efficient.

Request for a quote

ZUMBACH ELECTRONIC AG

Switzerland

Rugged and compact 7" capacitive Touch Screen. This universal PoE (Power over Ethernet) powered touch screen enables display of the integrated web interface of the connected ZUMBACH sensor device. Such as ODAC, ODEX and MSD diameter and ovality gauges, KW lump/neckdowns detectors, Spark Tester systems, RAYEX S systems among others. Devices without PoE can be powered via the separate 24V input connector. Advantages / Features • Reactive performance • Kiosk mode gives intuitive user friendliness • Hot pluggable with just 1 standard Ethernet cable • Up to 6 display characteristics – User definable • Set point and tolerance inputs with colour variation for fast indication of in or out of specification • Inbuilt terminal for extended device configuration/interrogation • Can be used as localized display or remote networked display • Base IP address can be re-configured to suit customized applications such as remote display within factory network.

Request for a quoteResults for

Parameters - Import exportNumber of results

22 ProductsCountries

Company type