- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- metallized ceramics

Results for

Metallized ceramics - Import export

WMC SINTERSTAR AG

Switzerland

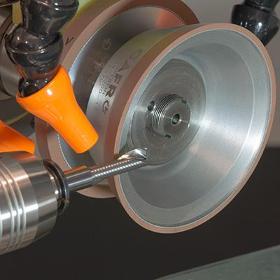

WMC Sinterstar AG represents the company Mirka (Cafro) in Switzerland. Cafro diamond and CBN grinding wheels are characterised by innovative bonds and high cutting ability for machining hard metal, ceramics and steel. Cafro's core competence is the production of resin bonded diamond and CBN grinding wheels. Over the years, the company has also specialised in the manufacture of metal-, hybrid-, ceramic-bonded and electroplated grinding wheels and PCD/PCBN tools. Our employees will also find the optimal grinding solution for your company. We benefit from our own knowledge and experience as a carbide manufacturer.

Request for a quote

ZEPTER INTERNATIONAL

Switzerland

Made from the finest stainless steel, the insides of the TAIGA cups are electro-polished to create a smooth finish - without having an unpleasant, metallic taste. Unlike plastic and ceramic cups, they do not retain the flavour of the previous drink. The double wall cups are excellent for hot or cold beverages! Presentation A REAL INVESTMENT: TAIGA IS DURABLE, VERSATILE AND ECO-FRIENDLY Versatility – a characteristic that best sums up the TAIGA Stainless Steel set. It is impossible to name all the drinks you can enjoy using it. From water to wine, from hot teas to ice teas, hot chocolate to soft drinks, fruit juices to beer, this set is ideal for you and your family to enjoy your favourite beverages. The TAIGA cups are specially designed to preserve the specific taste of each drink. The saucers and cups are harmoniously at one, giving an elegant touch to each table.

Request for a quote

MAXON MOTOR AG

Switzerland

Compact, easily configurable spindle drives as complete systems. With integrated ball bearings for high axial loads. Versions with metric ceramic or metal spindle. Custom lengths and special flange nuts available on request.

Request for a quote

MAXON MOTOR AG

Switzerland

Compact, easily configurable spindle drives as complete systems. With integrated ball bearings for high axial loads. Versions with metric ceramic or metal spindle. Custom lengths and special flange nuts available on request.

Request for a quote

MAXON MOTOR AG

Switzerland

Compact, easily configurable spindle drives as complete systems. With integrated ball bearings for high axial loads. Versions with metric ceramic or metal spindle. Custom lengths and special flange nuts available on request.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

MAXON MOTOR AG

Switzerland

Compact, easily configurable spindle drives as complete systems. With integrated ball bearings for high axial loads. Versions with metric ceramic or metal spindle. Custom lengths and special flange nuts available on request.

Request for a quote

NOVA WERKE AG - NOVA SWISS

Switzerland

Isostatic presses are specifically developed and manufactured by Nova Swiss Sarl in accordance to customer requirements. Cold, warm and hot presses are available for use at up to 10,000 bar and at temperatures from -20 to 2,200°C. Applications Sintering of powders for the production of complex geometries with high resilience. (Plastic, ceramic, graphite, metal, etc.) Sterilization of food Pressure / temperature simulations Hardening of mechanical parts Elimination of natural porosities in raw metallic materials Pressing of sintered parts (carbides, steels, etc.)

Request for a quote

NOVA WERKE AG - NOVA SWISS

Switzerland

Thermal spraying processes (as classified in the EN 657 and ISO 14917 standards) offer a wide range of applications within modern surface technologies. Components made from a wide range of base materials can be coated with layers of high-melting-point metals or ceramics to protect them against wear and corrosion. Furthermore, thermally conductive or heat-insulating layers can be applied to highly thermally stressed components. Almost all coating materials that can be produced in powder or wire form can be processed in this way. During thermal spraying, the coating materials are fed into — and melted by — an energetic heat source (fuel gas oxygen flames from combustible gas, arcs or plasmas of noble gases such as argon, hydrogen, nitrogen, helium). The particles, which are either softened or fully molten, are accelerated in the direction of the workpiece and collide with it at high speed (40–600 m/s).

Request for a quote

BÜCHI AG

Switzerland

Metal-free magnetic coupling bmd 250 i / cyclone 250 i ac Torque: 250 Ncm Temperature range: - 20 °C to +250 °C Pressure range: full vacuum - 60 bar / 1000 psi Stirrer speed: 0 - 2500 rpm Materials: ceramic Metal-free magnetic couplings (bmd 250 i) and stirrer drives (cyclone 250 i ac) feature inert behavior and full corrosion resistance, as no metal can get in contact with the process media. Built in our reactor systems versoclave, polyclave, kiloclave and in combination with pressure vessels in glass or glass-lined steel, we offer complete metal-free solutions.

Request for a quote

ENDRESS+HAUSER AG

Switzerland

Measuring points with extremely high process temperatures require these special thermometers with ceramic or metal thermowells as well as thermocouples made from special metals, such as platinum and rhodium. The thermowell made from special materials protects from mechanical and chemical damages in the process and increases the life span of the used sensors. This leads to: Cost savings for maintenance of the measuring point, quality improvements of the products and increased plant safety.

Request for a quote

COATMASTER

Switzerland

Coatmaster Inline Decrease setup time for your process. Save material. Document continuously. Advanced Thermal Optics by coatmaster The coatmaster technology (ATO) allows the thickness of the coating to be measured immediately after application. The technology operates contactless and non-destructive without dangerous emissions and is suitable for coating metal, paper, rubber, ceramics, glass, plastic and wood surfaces.

Request for a quote

COATMASTER

Switzerland

Just pick it up and start measuring. This handheld is the most innovative one in terms of contactless coating thickness measurement. Would you like to measure the coating thickness early in the process in order to save material and avoid coating mistakes? Then the coatmaster Flex is the right measurement device for you. Optimize your process and get your coatmaster Flex now. If you are not completely satisfied within the first 30 days after delivery, you can return it free of charge.The coatmaster technology (ATO) allows the thickness of the coating to be measured immediately after application. The technology operates contactless and non-destructive without dangerous emissions and is suitable for coating metal, paper, rubber, ceramics, glass, plastic and wood surfaces.

Request for a quoteResults for

Metallized ceramics - Import exportNumber of results

13 ProductsCountries

Company type