- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- weights

Results for

Weights - Import export

ELMOR

Switzerland

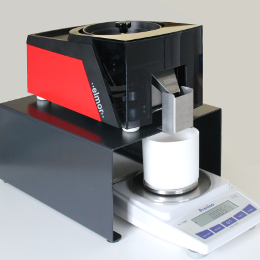

With seed tests the 1000 kernel weight is an important quality criterion, which must be determined with high accuracy. Counting and dosage of mechanical and electronic small articles as SMD’s are made increasingly also over the determination of the 1000 grain weight. By means of an additional software module, an electronic balance and a special frame, our precision counter C3 can be used for the direct determination of the 1000 kernel weight of a sample. Both the C3 as well as a balance are connected with the control computer. A freely selectable quantity is counted and falls on the scale pan. At the end of the counting operation the weight of the sample and the corresponding number of particles is transmitted automatically to the PC, where the 1000 kernel weight is calculated. With the conventional 1000 grain weight determination, the number of items and the weight must be entered manually into a calculating machine. In many cases, exactly 1000 kernels are counted and weighed; and then the 1000 grain weight can be determined without arithmetic exercise, but the danger exists that the result is falsified by separation effects during the operation of the vibrating conveyor (grain size selection). With the simultaneously determination of seed quantity and weight all potentially faulted manual inputs are eliminated. If necessary the result can be printed out or processed electronically. Further the danger of the grain size selection can completely be avoided. Technical data Scales are available with a resolution of 1 mg, 10 mg or 100 mg. The data of the elmor C3 seed counter and the scale are sent to the control computer via two RS232 ports or – on request – with two USB cables.

Request for a quote

ELMOR

Switzerland

Single grain seed weight analyser and seed weight sorter. The elmor SWS opens new possibilities for breeding and quality control of grain, corn, oilseeds, legumes and vegetables. Moreover a variety of applications arise in environmental monitoring. Weight distributions of selected samples (kernels of individual ears, selected generations of breeding programs etc.) are determined in statistically relevant quantities, automatically and unattended. In addition, due to the possibility of sorting, a targeted selection according to the individual kernel weight (seed weight selection / seed mass selection) can be realized. The Seed Weight Sorter (SWS) can be used as seed weight analyser for large amounts of individual kernels. It can run unattended and with high accuracy. In addition, the tested parts can be sorted. As sorting criterion, a weight limit (above / below the limit) or a window value (inside / outside the window) can be selected. The seed weight sorter consists of an C1 counting device that runs in single grain dosing mode. The weight of each individual grain is measured using a high speed high accuracy weigh module for industrial environmental conditions from METTLER TOLEDO. This precision balance has a readability of 10 Milligram, 1 Milligram or 100 Micrograms. The rugged industry scale is largely insensitive to dust, making it suitable for tough continuous operation even in harsh environment. A pneumatic sorting cell transfers the weighted parts according to the measured weight value into one of two bins. The entire process and the storage of all weight values are controlled by a Windows-based PC. The file with all weight data can be exported via XML protocol for further processing with relevant software. Technical data For parts ranging from 2 mm to 10 mm diameter Available resolutions of the scale: 10 mg, 1 mg, 0.1 mg Modes of operation: Serial weight protocolling without sorting Sorting with one predetermined weight limit Sorting according to the moving average Sorting with two limits: inside or outside of a defined range Obtained data when parts are sorted with one limit: Number of weighted particles Weight total Average weight, all particles Particles in the right bin Weight right Average right Percentage right Particles left Weight left Average weight left % left 1000 Grain Weight total 1000 Grain Weight right Time consumption per operation: typically 2 to 4 seconds, depending on the resolution of the scale Operational autonomy The sorter can run unspervised for many hours. It stops when one of the following conditions is true: when a preselected number of parts is weighted when a preselected number is sorted into the right bin when a preselected total weight is processed when a preselected weight is sorted into the right bin when one of the sorting bins is full. System requirements for the control PC: Operating system Windows XP, 7 or 8 .NET Framework 4.5 or higher 2 RS232 or USB Ports Dimensions / weight W x D x H: 390 x 470 x 460mm, 25kg Media Power supply: 230 V, 50 Hz or 120 V, 60 Hz. Other voltages / frequencies on request Pressurised air: dry and clean air, 0.6 MPa (6 bar) elmor Green Design Our label for: high energy efficiency longevity no standby power loss most components may be recycled production without solvents, ROHS conformity

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

Results for

Weights - Import exportNumber of results

2 ProductsCountries

Company type

Category