- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- scanning lasers

Results for

Scanning lasers - Import export

ZUMBACH ELECTRONIC AG

Switzerland

Laser measuring device for measuring diameter, ovality, circularity, width and height of round products and profiles Properties Cutting-edge optics and laser scan technology Maximum accuracy and stability Orientation-independent measurement Non-contact measurement of diameter and ovality Identification of lumps and neckdowns Extremely high sampling rate Permanently calibrated Integrated interfaces such as Ethernet IP, Profinet IO, Profibus DP and others Integrated web server in all processor versions Benefits • Maximum precision thanks to laser scan measuring principle • Robust and durable design • Extremely dirt resistant • Comprehensive quality control • High operational reliability even under harsh conditions • Measurement of opaque or transparent products • Position measurement possible. For accessories & detailed product information, refer to respective brochures on the following link from our website: https://zumbach.

Request for a quote

ZUMBACH ELECTRONIC AG

Switzerland

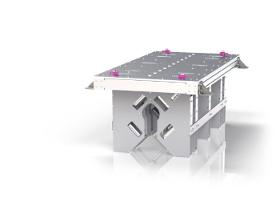

Thanks to the robust, dirt-resistant design of the Steelmaster, it is suitable for hot steel applications under production conditions with a lot of dirt and warm product and ambient temperatures. Properties Cutting-edge optics and laser scan technology Extremely high sampling rate Highest accuracy and stability; measurements independent of orientation Non-contact measurement of diameter and ovality Suitable for measurements under harsh conditions Interfaces such as Ethernet IP, Profinet IO, Profibus DP and others Integrated web server in all processor versions. Benefits High operational reliability even under harsh conditions Heat resistant, thanks to integrated heat shield and water cooling Protective system using air purging unit and blower Very robust and durable design Extremely dirt resistant.

Request for a quote

ZUMBACH ELECTRONIC AG

Switzerland

The QC 2 system consists of a high precision diameter measuring head, a motorized rotating sample holder with automatic sample ejection and a processor unit USYS 20 with special software evaluating the captured values. The system provides fast and accurate measurements of manufactured parts or cut samples. QC 2 can be used either in quality control (QC) laboratories or on factory floors. It provides operators a simple and repeatable solution for parts measurement and immediate notification of meeting specification within given tolerances. Unlike other micrometers or mechanical indicators that can give errors due to poor zero setting, end play, calibration or are sensitive to user input, QC 2 provides repetabale measurements regardless the operator. Benefits Fast and accurate measurements of manufactured parts or cut samples High precision thanks to laser scan measuring principle Own software for evaluating the captured values.

Request for a quote

ZUMBACH ELECTRONIC AG

Switzerland

Thanks to the robust, dirt-resistant design of the Steelmaster, it is suitable for hot steel applications under production conditions with a lot of dirt and warm product and ambient temperatures. Properties Cutting-edge optics and laser scan technology Extremely high sampling rate Highest accuracy and stability; measurements independent of orientation Non-contact measurement of diameter and ovality Suitable for measurements under harsh conditions Interfaces such as Ethernet IP, Profinet IO, Profibus DP and others Integrated web server in all processor versions. Benefits High operational reliability even under harsh conditions Heat resistant, thanks to integrated heat shield and water cooling Protective system using air purging unit and blower Very robust and durable design Extremely dirt resistant.

Request for a quote

ZUMBACH ELECTRONIC AG

Switzerland

The BENDCHECK system is suitable for in-line production optimization in the steel and metal industry. The measuring solution enables in-line quality assurance in the production of tubes and rods and eliminates the need for complex manual straightness measurements. Properties: Synchronous real-time scan to monitor bending of the product 3 to 5 non-contact measuring stations with 1 to 3 measuring axes Direct integration into the existing production process Constant quality assurance, also after the straightening process Recording of statistics, ensuring traceability Time savings thanks to automatic measurement control Continuous measurement without slowing down the production process Replaces manual measurements by means of off-line stations Optional measurement of head and tail bending with additional measuring stations. Benefits: Cutting-edge optics & laser scan technology Maximum accuracy & stability Extremely high sampling rate Comprehensive quality control

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

Results for

Scanning lasers - Import exportNumber of results

5 ProductsCountries

Company type