- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- recyclable products

Results for

Recyclable products - Import export

ELMOR

Switzerland

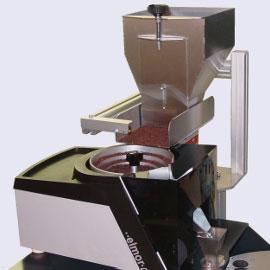

The feeding conveyor elmor 610 serves to refill the counting machines elmor C1, C3 or CX continuously and unattended. The feeding conveyor elmor 610 consists of a hopper, a feeding unit and a level sensor. Once the filling level in the conveyor bowl of the counting machine elmor C1, C3 or CX falls below a minimum value, it is automatically refilled through the feeding conveyor elmor 610. For small and light parts such as seeds, a linear vibratory conveying device is used. The hopper has 4 liters of storage volume. For large or heavy items refilling is done via a belt conveyor. The storage volume in this case is 10 liters or more. With the feeding conveyor elmor 610 a long operating autonomy is achieved, especially when the couning machine runs in combination with a filling or packaging machine. Technical data Suited for parts larger than 2 mm in diameter Type of conveyor: linear vibratory conveyor or belt conveyor Storage volume: 4 litres (vibratory conveyor) or 10 litres (belt conveyor) Level sensor: a precise sensor switches the conveyor on and off depending on the level to be regulated elmor Green Design Our label for: high energy efficiency longevity no standby power loss most components may be recycled production without solvents, ROHS conformity

Request for a quote

ELMOR

Switzerland

Seed counter, counter for small parts elmor C1 The elmor C1 is a universal counting machine for any small and irregularly shaped parts, such as: Finest plant seeds Vegetable seeds Cereals, Maize, Rice, Canola Insects, Pupae, Eggs Pharmaceuticals, pills, casules Gems, diamonds and precious stones Bulk semiconductor chips Small mechanical parts Implants All these products have in common is that they are either irregularly shaped, lightweigt or very small. Therefore these parts are difficult to handle manually. Dosing these parts with scales is often flawed or impossible. The seed counter C1 is specialized for exactly counting of such parts in small to medium quantities. Important applications of the C1 seed counter are the repetitive, precise counting of a preselected number of parts or the conventional determination of the 1000 grain weight according to ISO 520:2010. Parts with diameters from 0.2mm to about 18mm can all be processed with the same adjustable conveyor bowl. For fast counting of large amounts the 650 multi-channel counting machine can be used. The seed counter C1 is characterized by a robust construction, a fool-proof operation and a large, bright display that is easy to read even in daylight. The count signal is processed by a microprocessor which allows also the detection of parts with particularly difficult shapes. The parts counter C1 is equipped with terminals for remote control so that it can be combined, for example with packaging and filling machines. The C1 seed counter is the successor of our model 600, which was produced from 1980 for about 25 years. The new seed counter elmor C1 combines modern electronics with the proven key components that were already responsible in the previous model for long durability and unmatched accuracy. The C1 can be described with attributes such as longevity, durability, robustness and reliability – this for many years. Technical data Counter for small parts from 0.2 to 18 mm in diameter (*) Cylindrical parts can have a length of up to 20 mm (*) Only one adjustable conveyor bowl is used for the whole size range Conveyor bowl: anodised Aluminium, sorting element FS-0. Other bowls and sorting elements available on request Display and preset range of the counter: 0 to 99’999 Modes of operation: Preset counter, Totaliser The conveyor speed is reduced shortly before reaching the desired quantity to achieve a high dosing accuracy External connections allow the combination of the seed counter C1 with other devices, e.g. packaging machines. Typical performance data for spherical parts of 2mm diameter: Counting speed: about 50’000 parts per hour Counting error: 1/10’000 for clean, easy to separate parts Modes of operation: Totaliser Preset counter (*) other sizes on request The C1 counting machine is the central part of a system that can be adapted for many different applications. Some variants are standardized available, such as: Conveyor bowls for specific tasks Counter with dual product outlet Automatic seed weight sorter Filling carousel for bags and/or vials Filling adapter for containers Dust cover Ionizer Receipt printer Feeder / hopper with a few litres storage volume If your application can not be covered with these accessories, please contact us so that we can propose you a customized solution. elmor Green Design Our label for: high energy efficiency longevity no standby power loss most components may be recycled production without solvents, ROHS conformity

Request for a quote

ELMOR

Switzerland

The elmor 650 Multi-Channel Counter is primarily used as a fast seed counter, but also as a counter for any small parts, such as: Vegetable seeds Seeds of ornamental plants Cereals, Maize, Rice, Canola Pills, Pharmaceuticals small mechanical parts All these products have in common is that they are either irregularly shaped or very small and that they are difficult to handle manually. Dosing these parts with scales is often flawed or impossible. The 650 Multi-Channel Counter is specialized for fast counting and dosing of medium to large quantities. For counting and dosing of small quantities, our seed counter elmor C1 can be used. With the 650 Multi-Channel Counter, the product being counted is fed along different channels in parallel, separated and counted. The number of counting channels may be freely selected between 5 and 25. The counting channels are supplied via a supply hopper with a capacity of several litres. The counting speed is determined by the number of channels and the size and shape of the products. A multichannel counter with 25 channels can count more than 1 Million parts of 2mm diameter per hour. Like all machines from elmor, also the multichannel counters can be manufactured in different variants, in order to be combined optimally with other devices. Picture: 650 Multi-Channel Counter with 25 channels Technical data Count parts from 0.5 to 20 mm in diameter Modes of operation: Preset counter, Totaliser The conveyor speed is reduced shortly before reaching the desired quantity to achieve a high dosing accuracy. Counting error: 1/1000 or better The elmor 650 Multichannel Counter is controlled by a PLC, thus the combination with subsequent packing machines, fillers or printers is easily possible elmor Green Design Our label for: high energy efficiency longevity no standby power loss most components may be recycled production without solvents, ROHS conformity

Request for a quote

ELMOR

Switzerland

The elmor CX counter module is mostly used as dosing unit on packaging machines. The open constructed counting head has a narrow width. Thus, multihead dosing systems can be realized easily also in tight spaces. The CX counter module consists of two parts: the counting head with conveying unit and sensor and the control unit. The control unit of the CX counting module is completely remote controlled via a PLC. The technical data of the CX counter module are quite similar to the data of our C1 seed counter. Example: Dosing module with 4 counter heads Multihead seed counter using the elmor CX With courtesy of: Tempel Verpakkingstechniek (NL) For more information please contact: info@vandertempel.nl Technical data Countable parts: 0.2 to 18 mm in diameter Cylindrical parts up to 20 mm length All sizes are counted with the same adjustable conveyor bowl; for parts with extreme shapes or sizes the sorting element can be customized The conveying speed can slow down automatically shortly before reaching the desired amount to achieve a high dosing accuracy. Spherical parts of 2 mm diameter have the following performance values: Counting speed around 50,000 pieces per hour Counting error: 1 per thousand or less The counting range and the count modes are determined by the PLC Conveyor bowls The parts to be counted are transported in a vibrating conveyor and are singularised by means of a sorting element. Both the conveyor bowl as well as the sorting element can be selected among different variants , depending on the properties of the product to be counted. A) Standard conveyor bowl made of anodised Aluminium with universal – sorting element FS0. FS0 is manually adjustable for all part sizes from 0.1 to 18 mm in diameter. B) Special sorting elements instead of FS0: FS1, manually adjustable, optimised for cereals, rice, paddy and products of similar shape and size FS2: manually adjustable, optimised for corn, soybeans, peas, beans and products with similar shape and size FS3: fine-drive adjustable in height and width, for very flat seeds or flat mechanical parts with the following dimensions: width: 0.5 to 10 mm, height: 0.5 – 8 mm, maximum length: 20 mm C) Special conveyor bowl with additional lateral opening for mechanically eliminating of accompanying substances, suitable for corn, cereals, soybean, paddy, etc. The height of this opening can be adjusted from 0 to 5 mm and allows unwanted accompanying substances laterally be sorted out. Not suitable for parts smaller than 1 mm in diameter. Can be used with sorting elements FS0, FS1, FS2, or FS3 combined. D) To meet the needs of various industries, the conveyor bowls can be made of other materials . These bowls are for example extremely impact resistant or correspond to the rules of the FDA, etc. Such trays can be made from various basic materials like Titanium, PEEK, Polyamide and others. E) The standard aluminum bowls can be treated or coated in order to satisfy specific requirements. With increased mechanical stress or when in contact with food, the surface can be hard anodized. A hard coating of nickel has a high surface hardness and is FDA approved, Polyurethane (PU) coating permits rapid transport of heavy mechanical parts and prevents noise and wear. Again, FDA approved materials can be used. F) Feeder Bowl with vertical outlet: Short cycle times are possible, as the seeds leave the bowl after a short run time. Advantageous when many different lots must be processed, often used for the fast 1000 grain weight measurement. Used for seeds which can be easily singularised like Crop, Soy, Corn, Canola etc. The seeds should have a diameter of 2 mm or more. Volume 0.8 litres, or about 2500 kernels of Corn. Feeding Conveyor elmor 610 Feeding conveyor and storage hopper for automatic refilling of the conveyor bowl of the counting machine elmor CX elmor Green Design Our label for: high energy efficiency longevity no standby power loss most components may be recycled production without solvents, ROHS conformity

Request for a quote

ELMOR

Switzerland

Equipment with a modular design for sorting and counting differently colored small articles within the mm range. The elmor colour sorter is inteded for laboratory use with a sorting capacity of 10’000 to 20’000 parts per hour for each channel, which corresponds to about 1 to 2 kg per hour per channel. The parts which have to be sorted are transported and singularised in a linear multichannel conveyor stage. The individual fractions are distributed corresponding to their colour into 2 or more containers. On request the elmor colour sorter can also count the fractions, so that mixtures of differently coloured particles can be quantitatively analysed. In order to get the requested sorting capacity, the devices can be equipped with 1 to 25 parallel channels. If the parts do not need to be counted, the number of channels is not limited. Thus the output per hour and the necessary investments can be selected individually upon the given conditions. The elmor colour sorted is intended for laboratory use for clearly defined sorting tasks; the throughput in the range of kg per hour is too low for the industrial sorting of rice, grain and other cereals, where tons per hour are requested. Technical data Modular sorter with parallel sorting channels The product to be sorted is transported and singularised on a linear conveying channel Each channel has an own colour detector, which is selected corresponding to the requested sorting task Additionally the detected parts per channel can be counted The number of parallel channels is theoretically illimited. If the fractions are counted, the maximum number of channels is 25. Typical sorting speed per channel: 2 parts per second parts with 2mm diameter or larger can be processed. elmor Green Design Our label for: high energy efficiency longevity no standby power loss most components may be recycled production without solvents, ROHS conformity

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

ELMOR

Switzerland

The elmor 780 carousel filler can be combined with all of our counting devices; particularly with the seed counters C1 and elmor C3 or with the multichannel seed counters elmor 650. The carousel filler allows semi automatic, to a large extent unsupervised filling of vials, tubes, small containers as well as bags from paper, glassine or composite material. The carousel tray can easily be removed and reinserted and the control circuitry of the equipment recognizes automatically if a tray has empty positions; these positions are skipped so that no seeds get lost. The carousel filling devices are individually designed depending upon the requirements of the customers. The type and size of the containers as well as the number of positions per tray can be selected within wide range. Examples Top: C1 seed counter with a carousel filler built for 12 glassine bags. Middle: C1 seed counter with a carousel filler built for 16 glass dishes used for sample preparation in a seed quality test lab. Bottom: Carousel insert for 25 Eppendorf tubes (trademark of Eppendorf) Technical description The Carousel filling device consists of a base unit with control and drive and the removable carousel insert made of stainless steel. The containers are loaded or unloaded using the taken-out carousel. With two or more carousel inserts, a high filling throughput can be achieved. The number of positions depends upon the width of the bags, respectively, the diameter of the container. The maximum number of filling positions amounts to 15 bags or 25 containers. A special version of the basic device also allows the processing of two different position numbers in the ratio 2:1, for example, 24 tubes or 12 bags. In the base unit a maintenance-free drive is installed which needs no adjustments. This results in a long service life even in rough and dusty environments. The carousel can be equipped with any type of containers. Examples are: Glassine bags, envelopes, vials, small containers or tubes with only a few mm in diameter. Before each filling operation, it is checked whether a container is present or not at the current position. Empy positions are skipped to avoid a loss of parts to be filled. Modes of operation Automatic: all positions of the carousel are filled, then the device stpos and waits until it is restarted. Permanent: the positions will be filled permanently. The filled containers can manually be replaced. Dimensions: 360 x 600 mm, the height depends of the container height. Weight about 20kg elmor Green Design Our label for: high energy efficiency longevity no standby power loss most components may be recycled production without solvents, ROHS conformity

Request for a quoteResults for

Recyclable products - Import exportNumber of results

7 ProductsCountries

Company type

Category