- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- precision sensors

Results for

Precision sensors - Import export

INNOVATIVE SENSOR TECHNOLOGY IST AG

Switzerland

The IST AG PW RTD sensor has been developed as an alternative to the traditional wire-wound sensors. The PW sensor combines the advantages of high accuracy and precision of the wire-wound sensors with the advantages of thin-film sensors that offer robustness, small dimensions and very low hysteresis at an optimal price level. Compared to a standard thin-film sensor measuring up to +300 °C in IEC 60751 F0.15 (IST AG reference class A), the IST AG PW sensor measures with high accuracy up to IEC 60751 F0.15 (IST AG reference class A) within a wide operating temperature range from -200 °C to +600 °C. Due to the special construction and stable characteristics curve, the IST AG PW sensor is also suitable for low temperature applications. As an additional feature, the PW sensor is available in round ceramic housing with the same dimensions as a traditional wire wound sensor, meaning easy interchangeability into existing temperature applications.

Request for a quote

KELLER PRESSURE

Switzerland

The high-precision level sensors of the 36XiW series measure with ultra-high accuracy and resolution. Temperature dependence and nonlinearity are precisely compensated for in the microprocessor by means of a mathematical model. They can be supplied with either an RS485 or SDI-12 interface. In addition to the pressure sensor for the level measurement, it is also possible to integrate a Pt1000 that is calibrated to ±0,1 °C from 0...50 °C. Extended lightning protection comes as standard with the SDI-12 interface and is available as an option for the RS485 interface.

Request for a quote

KELLER PRESSURE

Switzerland

In the high-precision level sensors of the 36XW series, the temperature dependence and nonlinearity are precisely compensated for in the microcontroller by means of a mathematical model. In addition to the RS485 interface, the measurement results can also be output via the integrated D/A converter as a rangeable analog signal. Extended lightning protection is also available as an option.

Request for a quote

MAGTROL

Switzerland

With its compact, bearingless, maintenance-free design, the new TF Torque Flange Sensor from Magtrol brings many appealing advantages to torque measurement applications. The TF’s high torsional rigidity supports direct mounting on the machine shaft or flange, avoiding the use of couplings on one side. This allows easy integration into a test system, shortens the overall length of the test bench and reduces costs. Based on strain-gauge technology, the TF Sensor’s precise telemetry system enables highly accurate signal transmission. A signal amplifier mounted in the measuring flange amplifies the measuring signal, modulates it to high frequency and transmits it inductively (via the HF transmitter) to the receiver. In the receiver, the digitized torque signal is transformed into an analog output signal of ±10 VDC. Rotational speed can be measured and converted to a TTL output signal with the optional speed pickup. more info www.magtrol.com

Request for a quote

ENDRESS+HAUSER AG

Switzerland

The Prowirl D measuring tube is a disc/wafer model. The flowmeter is installed between flanges and mainly used for light duty applications. The proven and patented capacitive DSC sensor ensures high precision measured values. Prowirl D 200 offers industry-compliant two-wire technology for seamless integration into existing infrastructures and control systems, as well as high operational safety in hazardous areas thanks to an intrinsically safe design, and a familiar installation procedure.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

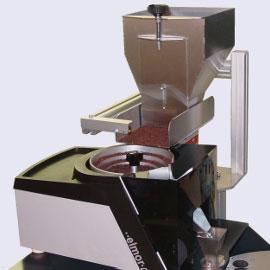

ELMOR

Switzerland

The feeding conveyor elmor 610 serves to refill the counting machines elmor C1, C3 or CX continuously and unattended. The feeding conveyor elmor 610 consists of a hopper, a feeding unit and a level sensor. Once the filling level in the conveyor bowl of the counting machine elmor C1, C3 or CX falls below a minimum value, it is automatically refilled through the feeding conveyor elmor 610. For small and light parts such as seeds, a linear vibratory conveying device is used. The hopper has 4 liters of storage volume. For large or heavy items refilling is done via a belt conveyor. The storage volume in this case is 10 liters or more. With the feeding conveyor elmor 610 a long operating autonomy is achieved, especially when the couning machine runs in combination with a filling or packaging machine. Technical data Suited for parts larger than 2 mm in diameter Type of conveyor: linear vibratory conveyor or belt conveyor Storage volume: 4 litres (vibratory conveyor) or 10 litres (belt conveyor) Level sensor: a precise sensor switches the conveyor on and off depending on the level to be regulated elmor Green Design Our label for: high energy efficiency longevity no standby power loss most components may be recycled production without solvents, ROHS conformity

Request for a quoteResults for

Precision sensors - Import exportNumber of results

7 ProductsCountries

Company type