- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- packaging systems

Results for

Packaging systems - Import export

BOGRAMA AG

Switzerland

With the new Automated Card Production System for inline die-cutting, collating and stacking of playing cards you can die-cut a wide range of cards including playing cards, gaming cards, trading cards and sports cards and they can be stacked and delivered in one step. The system consists of the market leading BSR 550 Servo rotary die-cutter, feeding into the ACC 550 HS Automatic Card Collator. The cards are die-cut nick-free, stripped out inline, shingled and fed to the ACC 550 HS Card Collator via a conveyor belt. The ACC 550 HS stacks each row into a complete deck and feeds it to a downstream packaging system that may include over wrappers, banding machines, packaging machines or packing table conveyors. With production rates of up to 2,000 decks per hour, the highest quality cutting, makeready times in under 1 hour and an automated delivery that reduces labor to a single person, the BOGRAMA Automated Card Production System has the ROI needed to be the market leader.

Request for a quote

BOGRAMA AG

Switzerland

In this configuration variant, products are fed to the punching area individually from the pallet feeder and rotary punched by using a flexible die. The maximum stack height of the feeder is 100 cm. The sheet alignment on the side is performed with a register table with ball rail. The position accuracy in the direction of production is realised with a positioner roller system that causes the sheets to pass the punching cylinder with high precision without stopping. Inline configuration of the die-cutting machine with machines interfaced downstream such as folding machines, mailing systems and packaging machines is the most efficient way of carrying out multiple high-performance steps in one operation. Automatic discharging of section grids and simultaneous separation of inner cuts increase production in addition. The format range of the BSR 550 Servo is from 550 x 750 mm to 210 x 210 mm. Sheets having a product thickness between 0.5 mm and 80 g/m2 can be processed.

Request for a quote

BOGRAMA AG

Switzerland

Individual products are fed to the punching area from the flat pile feeder and punched with the rotating flexibe die. The sheet alignment on the side is performed with a register table with ball rail. The position accuracy in the direction of production is realised with a positioner roller system that causes the sheets to pass the punching punching cylinder with high precision without stopping. Inline configuration of the die-cutting machine with machines interfaced downstream such as folding machines, mailing systems and packaging machines is the most efficient way of carrying out multiple high-performance steps in one operation. Automatic discharging of section grids and simultaneous separation of inner cuts increase production in addition. The format range of the BSR 550 Servo is from 550 x 750 mm to 210 x 210 mm. Sheets having a product thickness between 0.5 mm and 80 g/m2 can be processed. The maximum capacity of the machine is 12,000 sheets/h

Request for a quote

VELTRU AG

Switzerland

Fast handling equipment is often used in processes where volumes can not be handled by one robot only. The product architecture of VELTRU has multi-robot systems in mind. Our customers may download the corresponding Application Notes describing further technical details from our FTP. VELTRU is able to offer its customer access to all three major concepts for multi-robot lines: Assortment configuration The assortment is where several different products are combined into one packaging, common for chocolate and confectionery applications. Each product is fed on an individual conveyor, perpendicular to the conveyor for the packaging. Parallel flow configuration In systems with one product type only, the products and the packaging are transported in parallel direction. If moving into the same direction, the last robot will have few products to fit into few cavities of the packaging. This typically leads to errors such as products not being packaged and packaging not getting completely fill

Request for a quote

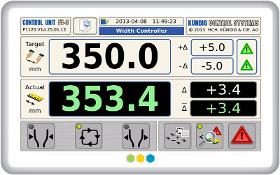

HCH. KÜNDIG & CIE AG

Switzerland

The FE-8 is a modular system to measure and control the layflat width on blown film lines. It can be used as a simple measuring device or as a stand-alone control system package. The non-contact measuring bar detects the edges of the film by two infrared sensors. In this way, it calculates the layflat width. The advantage of this measuring method is that the real layflat width is registered, after the shrinking of the film. Hence the FE-8 is an important device also on lines where the bubble circumference is measured. Application: The FE-8 is a layflat width measuring and control system for blown film lines. Download: Brochure Options: Profilstar.NET

Do you sell or make similar products?

Sign up to europages and have your products listed

Results for

Packaging systems - Import exportNumber of results

5 ProductsCountries

Company type