- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- filling of cans

Results for

Filling of cans - Import export

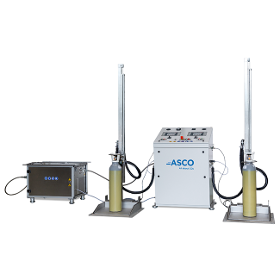

ASCO CARBON DIOXIDE LTD

Switzerland

The ASCO LH900 Liquid CO2 Filling Pump has been developed as an universal unit for filling high pressure CO2 cylinders by weight. Like all ASCO Equipment, the Cylinder Filling and Weighing System is thoroughly factory pretested before despatch. Thanks to the separate control unit, the pump can be placed in a different location. Easy operation Switch on your ASCO LH900 and the unit automatically tares itself to „0“ which will show on the indicator display. After placing a cylinder on the platform, the display will show the accurate tare weight of the cylinder, allowing the operator to check whether the empty cylinder weight is correct. The chosen filling weight can now be set on the display by pressing the relevant keys (when filling the same size of cylinder, the filling weight needs only be entered once). When the desired filling weight is reached and displayed, the solenoid valves of the ASCO LH900 will automatically switch to run the system in bypass.

Request for a quote

KELLER PRESSURE

Switzerland

This high-pressure pump generates pressures of up to 700 bar with ease, with fine control for precise adjustment. It is perfect for testing manometers and pressure transmitters. The pump must be filled with 100 cm3 of hydraulic oil or water and can therefore fill up even relatively large dead volumes. An additional manometer (not supplied) is needed for reference measurement of the configured pressure. KELLER recommends manometers in the LEX1 series with a suitable pressure range.

Request for a quote

ENDRESS+HAUSER AG

Switzerland

The Batch Controller RA33 is designed to record flow and control output signals for valves and pumps to ensure the exact dosing of predefined batch quantities. The measured volume can be corrected with the temperature/density compensation function. The filling process can be optimized with an automatic or fixed after-run correction. Mineral oils can be corrected according to the ASTM D1250-04 standard.

Request for a quote

ELMOR

Switzerland

The packaging machine elmor 800 is a small, compact and versatile packaging machine for premade bags like seed sachets. The machine can be combined with all elmor seed counters, but also with counting devices from other manufacturers or with other dosing devices such as dosing scales or volume-dosing machines. The seed counting and packaging machine elmor 800 can fill and close sealable flat bags or pregummed bags. In addition to the filling and closing, the bags can also be marked with an inkjet printer. Changing of the bags requires only a few seconds. A replaceable bag stack allows changing to other formats without time-consuming adjustments. Just change the stack and continue. Therefore, the packaging machine elmor 800 is especially suited for the packaging of seed specialties or organic seeds where many different varieties, but mostly small batch sizes have to be packed. The packaging machine elmor 800 is designed as a table top model.

Request for a quote

ELMOR

Switzerland

The elmor 780 carousel filler can be combined with all of our counting devices; particularly with the seed counters C1 and elmor C3 or with the multichannel seed counters elmor 650. The carousel filler allows semi automatic, to a large extent unsupervised filling of vials, tubes, small containers as well as bags from paper, glassine or composite material. The carousel tray can easily be removed and reinserted and the control circuitry of the equipment recognizes automatically if a tray has empty positions; these positions are skipped so that no seeds get lost. The carousel filling devices are individually designed depending upon the requirements of the customers. The type and size of the containers as well as the number of positions per tray can be selected within wide range. Examples Top: C1 seed counter with a carousel filler built for 12 glassine bags. Middle: C1 seed counter with a carousel filler built for 16 glass dishes used for sample preparation in a seed quality test lab. Bottom: Carousel insert for 25 Eppendorf tubes (trademark of Eppendorf) Technical description The Carousel filling device consists of a base unit with control and drive and the removable carousel insert made of stainless steel. The containers are loaded or unloaded using the taken-out carousel. With two or more carousel inserts, a high filling throughput can be achieved. The number of positions depends upon the width of the bags, respectively, the diameter of the container. The maximum number of filling positions amounts to 15 bags or 25 containers. A special version of the basic device also allows the processing of two different position numbers in the ratio 2:1, for example, 24 tubes or 12 bags. In the base unit a maintenance-free drive is installed which needs no adjustments. This results in a long service life even in rough and dusty environments. The carousel can be equipped with any type of containers. Examples are: Glassine bags, envelopes, vials, small containers or tubes with only a few mm in diameter. Before each filling operation, it is checked whether a container is present or not at the current position. Empy positions are skipped to avoid a loss of parts to be filled. Modes of operation Automatic: all positions of the carousel are filled, then the device stpos and waits until it is restarted. Permanent: the positions will be filled permanently. The filled containers can manually be replaced. Dimensions: 360 x 600 mm, the height depends of the container height. Weight about 20kg elmor Green Design Our label for: high energy efficiency longevity no standby power loss most components may be recycled production without solvents, ROHS conformity

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

Results for

Filling of cans - Import exportNumber of results

5 ProductsCountries

Company type