- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- coated wire

Results for

Coated wire - Import export

INNOVATIVE SENSOR TECHNOLOGY IST AG

Switzerland

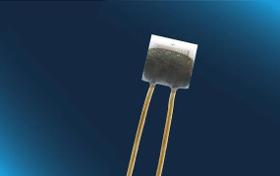

The IST AG 300 °C Pt Temperature Sensor Series offers an excellent long-term stability and fast response time with low self-heating within a temperature range of -200 °C to +300 °C. The sensors offer a stable performance at a low price and are available with Au-coated Ni-wire which makes them ideal for soldering, brazing, crimping and laser welding. Furthermore, the 300 °C Pt Temperature Sensor Series can be customized to fit application-specific requirements e.g. wire lengths or lead wire diameters. The IST AG Pt temperature sensors up to 300 °C are also available with: — Metallized backside — Inverted or perpendicularly bended wires

Request for a quote

INNOVATIVE SENSOR TECHNOLOGY IST AG

Switzerland

The IST AG 200 °C Ni Temperature Sensor Series offers an excellent long-term stability and simple linearization within a temperature range of -60 °C to +200 °C. The sensors are offered with Ag-wire (Ø 0.25 mm), with Au-coated Ni-wire or flat wire and with Cu/Ag-wire with PTFE-insulation in various standard lengths. The directly welded wires offer outstanding robustness and are optimal for soldering, welding and crimping. The nickel temperature sensors are vibration and temperature shock resistant with simple interchangeability and small dimensions. Furthermore, the 200 °C Ni Temperature Sensor Series can be customized to fit application-specific requirements. The IST AG nickel temperature sensors up to 200 °C are also available with: — Wire lengths fitted to application-specific requirements — Insulated wires — Flat wires — Metallized backside

Request for a quote

INNOVATIVE SENSOR TECHNOLOGY IST AG

Switzerland

The IST AG 300 °C Pt Temperature Sensor Series offers an excellent long-term stability and fast response time with low self-heating within a temperature range of -200 °C to +300 °C. The sensors offer a stable performance at a low price and are available with Au-coated Ni-wire which makes them ideal for soldering, brazing, crimping and laser welding. Furthermore, the 300 °C Pt Temperature Sensor Series can be customized to fit application-specific requirements e.g. wire lengths or lead wire diameters. The IST AG Pt temperature sensors up to 300 °C are also available with: — Metallized backside — Inverted or perpendicularly bended wires

Request for a quote

INNOVATIVE SENSOR TECHNOLOGY IST AG

Switzerland

The IST AG 300 °C Pt Temperature Sensor Series offers an excellent long-term stability and fast response time with low self-heating within a temperature range of -200 °C to +300 °C. The sensors offer a stable performance at a low price and are available with Au-coated Ni-wire which makes them ideal for soldering, brazing, crimping and laser welding. Furthermore, the 300 °C Pt Temperature Sensor Series can be customized to fit application-specific requirements e.g. wire lengths or lead wire diameters. The IST AG Pt temperature sensors up to 300 °C are also available with: — Metallized backside — Inverted or perpendicularly bended wires

Request for a quote

INNOVATIVE SENSOR TECHNOLOGY IST AG

Switzerland

The IST AG 300 °C Pt Temperature Sensor Series offers an excellent long-term stability and fast response time with low self-heating within a temperature range of -200 °C to +300 °C. The sensors offer a stable performance at a low price and are available with Au-coated Ni-wire which makes them ideal for soldering, brazing, crimping and laser welding. Furthermore, the 300 °C Pt Temperature Sensor Series can be customized to fit application-specific requirements e.g. wire lengths or lead wire diameters. The IST AG Pt temperature sensors up to 300 °C are also available with: — Metallized backside — Inverted or perpendicularly bended wires

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

INNOVATIVE SENSOR TECHNOLOGY IST AG

Switzerland

The IST AG 300 °C Pt Temperature Sensor Series offers an excellent long-term stability and fast response time with low self-heating within a temperature range of -200 °C to +300 °C. The sensors offer a stable performance at a low price and are available with Au-coated Ni-wire which makes them ideal for soldering, brazing, crimping and laser welding. Furthermore, the 300 °C Pt Temperature Sensor Series can be customized to fit application-specific requirements e.g. wire lengths or lead wire diameters. The IST AG Pt temperature sensors up to 300 °C are also available with: — Metallized backside — Inverted or perpendicularly bended wires

Request for a quote

STAMIXCO AG

Switzerland

StaMixCo manufacturers all three commercially proven static mixer designs used for high viscous melt flow mixing of polymers in extrusion service. As with most process equipment, each static mixer design has specific advantages and disadvantages that make it more or less suitable for a specific application and installation. Each type of motionless mixer is discussed below: Process Improvements: Temperature gradients are virtually eliminated. Viscosity gradients are virtually eliminated. Composition gradients of colorant, chemical additives, fillers and regrind are virtually eliminated. Stagnant polymer wall-creep material is incorporated into the bulk polymer stream. Extrusion Applications Static Mixers are used in most extrusion applications including the following: Sheet Blown Film Foam sheet Profile extrusion Co-extrusion Pipe Extrusion Blow Molding Rod & Tubing Wire & Cable Coatings Fiber extrusion & monofilaments Benefits Reduction of color additives with comparable extrudate color density. Even thickness across the entire extrudate width. Streak-free product. Improved quality when using regrind material. Foam cell size and cell distribution uniformity. Improved surface quality Improved mechanical characteristics. Rapid color change-over SMB-R Static Mixer SMB-GXS Static Mixer Mixing of blue and white epoxy resin with the SMB-GXS Static Melt Blender. It improves the melt homogeneity by factor 5-6. SMB-R Static Mixer The SMB-R static mixer for extrusion service (licensee of Bayer AG, Leverkusen, Germany) contains eight (8) very efficient motionless mixing elements that homogenize the polymer melt as it enters the extruder die. The SMB-R mixing elements are considered as high performance design where they create a very high degree of mixing in a short length. The SMB-R mixing elements are virtually indestructible due to their monolithic cast construction where the mixing bars are jointed to each other and to the ring wall via a single molten metal pour. Mixing of blue and white epoxy resins. Empty tube (top)provides no mixing. Eight (8) mixing elements (bottom) provide an excellent mix quality in a short length. SMB-GX Static Mixer Melt Blender The SMB-GX motionless mixer is a design that has been used in melt flow mixing extrusion service for over 25 years. The SMB-GX mixing elements are considered as high performance design where they create homogeneous mix in a short length. It has the same fundamental X-Grid crossing-bar structure as the StaMixCo SMB-R static mixer (Figure #8), but without the support ring around the mixing blade structure which gives the SMB-R its remarkable strength. Since the SMB-GX is manufactured from metal plates that are welded together, virtually any custom static mixer plate thickness, material and diameter can be fabricated to meet process and installation requirements. SMB-H Static Mixer Melt Blender The SMB-H Helical static mixer design pioneered the static mixing industry and has been used as a viscous static mixer on extruders for over 37 years. The Helical design is considered a low mixing performance-long length-low pressure drop motionless mixer as compared to the later developments of high performance static mixers such as the SMB-R and SMB-GX which have become the technology standards in the industry. StaMixCo manufactures SMB-H static mixers by advanced proprietary manufacturing technique where the entire unit is machined from a solid rod of bar stock material without welding. This machining process allows for custom static mixer fabrication in virtually any L/D twist, in very small sizes, with very high strength, straight and true dimensioning and with a RMS 12 mirror polish surface finish which is a much improved surface finish as compared to the traditional 32 RMS finish for the twisted and welded design.

Request for a quoteResults for

Coated wire - Import exportNumber of results

8 ProductsCompany type

Category