- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- industry 4.0

Results for

Industry 4.0 - Import export

EOSWISS PHARMA

Switzerland

We carry out the entire technology transfer or production transfer from a manufacturer to a contract manufacturer (CMO, CDMO) for you. Contact us for an initial discussion! In the process, we look for the right CMO for you and prepare a pre-selection. You decide on the best manufacturer, then we carry out the entire transfer for you: •Planning resources •Timetable including work packages •Structure the cooperation with the CMO •Prepare all necessary documents •technical transfer •Adjusting the production parameters, optimisation •we validate the transferred production process •handed over to routine production We bring all the necessary specialists into the project ourselves, or work hand in hand with your internal team. Depending on how it is needed. We carry out transfers very quickly. This shortens the project duration and reduces your costs: They are quickly back on the market! This reduces transfer costs in the long term. Contact us for an initial discussion!

Request for a quote

EOSWISS PHARMA

Switzerland

We manage investment projects for you, such as production expansions, installation of new plants, greenfield construction projects, brownfield construction projects. We focus on the rapid implementation of your project. With these short project durations, you have low project costs and a high return on investment. We adapt our project management to the very specific circumstances of our clients Contact us for an initial discussion! This makes our project management flexible enough to handle the changes that occur in every project. Our focus is on short "time to market" and thus low project costs. This is the only way for projects to pay off quickly. We execute projects very quickly and achieve significant time savings compared to traditional project management. Pharmaceutical production •After qualification and commissioning, we also take care of the start of production. •Optimisation of the production parameters •Validation •Transfer to routine operation

Request for a quote

ASCO CARBON DIOXIDE LTD

Switzerland

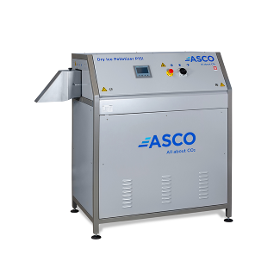

At ASCO, iSeries stands for networked production. Whether for fast and efficient problem solving and machine maintenance or for recording production and performance data, the iSeries offers a range of possibilities to connect Industry 4.0 and dry ice production. All iSeries models are equipped with the latest remote maintenance technology and thus offer a variety of services in the areas of remote access, remote data and remote management.

Request for a quote

ASCO CARBON DIOXIDE LTD

Switzerland

The ASCO Dry Ice Pelletizer P15(i) is a compact and powerful dry ice machine from our iSeries line. Having a production capacity of 150 kg/h (331 lb/h) it meets the demands for higher dry ice quantities plus quality and flexibility in the daily working process. As an optional model of ASCO's iSeries, it can be equipped with stateoftheart remote control devices and thus is ready for a wide range of services in the areas of Remote Access, Remote Data, Remote Management. Whether for fast and efficient trouble shooting and maintenance or for gathering production and performance data the ASCO iSeries offers a wide range of possibilities to link Industry 4.0 with dry ice production. The ASCO Dry Ice Pelletizer P15(i) is driven by a powerful hydraulic unit featuring instant push button start. All functions are controlled by a Siemens PLC with touch screen.

Request for a quote

ASCO CARBON DIOXIDE LTD

Switzerland

The ASCO Dry Ice Pelletizer P55i is one of the most powerful dry ice machines from ASCO's iSeries line. Having a production capacity of 550 kg/h (1'212 lb/h) it meets the demands for high dry ice quantities plus quality and flexibility in the daily working process. As a model of ASCO's iSeries, it is equipped with stateoftheart remote control devices and thus is ready for a wide range of services in the areas of Remote Access, Remote Data, Remote Management. Be it for fast and efficient trouble shooting and maintenance or for gathering production and performance data the ASCO iSeries offers a wide range of possibilities to link Industry 4.0 with dry ice production. The ASCO Dry Ice Pelletizer P55i is driven by two powerful hydraulic units, which are running independently by the push of a button. This allows the production of identical or different pellet sizes in combination with the offered extruder plates at the same time.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

ENDRESS+HAUSER AG

Switzerland

The Nivector FTI26 is a cost-efficient point level switch for solids in the food industry and powder applications in all industries. The capacitance device convinces with the best build-up performance in class and a high sensitivity. All industry compliant certificates are available. In addition, the FTI26 is industry 4.0 ready with IO-Link communication.

Request for a quote

MÜLLER MARTINI AG

Switzerland

Falling run sizes, short order workflows, a large number of orders in the system – these are all aspects of Industry 4.0 and mass customization. This results in new customer requirements and new requirements call for new solutions. Processes must be networked, systems linked, the production status clear at all times, machines integrated in business solutions, etc. Muller Martini’s Connex workflow solution is the answer to these new requirements. Connex modules connect production equipment with the main control systems via standard interfaces. “Just in time” evaluations and production feedback are only part of the solutions. We network not only all of our own production lines via our modules but lines from other suppliers as well.

Request for a quote

ZUMBACH ELECTRONIC AG

Switzerland

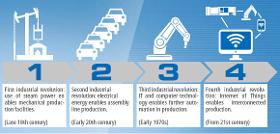

These days, everyone's talking about Industry 4.0. Are we facing something unknown or unheard-of? In actual fact, the technologies involved in Industry 4.0 are well-known; the concepts are visionary but not new. Much ado about nothing? Interconnecting physical objects with the virtual world using modern technology produces new working methods and business models that, set against current trends, are more evolutionary than revolutionary. The momentum surrounding Industry 4.0, however, should not be underestimated. Equipping components and machinery with sensors and software makes it possible to acquire field data automatically. Interconnection means this data can be retrieved in near real-time and collated at a central point. What could previously be seen directly at the components and machinery on the shop floor can now be visualised and monitored using software on a single platform. The result is maximum transparency. All data is provided at application level, making it easy to...

Request for a quoteResults for

Industry 4.0 - Import exportNumber of results

9 ProductsCountries

Company type