- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- sensor integration

Results for

Sensor integration - Import export

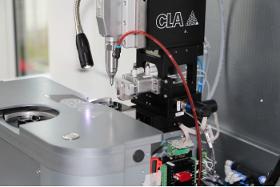

CLA CLINICAL LABORATORY AUTOMATION SA

Switzerland

Automatic screwdriver with torque measurement Compact station for workbench to ensure your assemblies screwed with high precision torque control. Main features : - Screws feeder by vibrating bowl - Preparation of the next screw in hidden time - Automatic screwdriver with integrated torque sensor - Preparation of the next part in hidden time thanks to the charging carousel - Removable precision tool to ensures a precise positioning and a multi-types parts management - User friendly interface allowing various screwing positions and configurations dedicated by type of parts - Ready to be integrate in assembly line

Request for a quote

MAGTROL

Switzerland

Magtrol’s Cogging Test System is a stand-alone test system designed to control and measure Detent Torque, Cogging Torque and Friction Torque. The test System includes a precision geared motor, a TS Series Torque Sensor integrating a 5 000 pulses encoder. CTS 100 to CTS 102 have a built-in security clutches to avoid system overload by mishandling when not in use. The geared motor drives the MUT (Motor Under Test) at a low speed from 1 to 10 rpm (respectively 8 rpm for CTS 103 and CTS 104), while acquiring its cogging torque related to angle position. The torque measurement covers a range up to 1 N∙m (depending on the selected torque sensor) with an accuracy of ± 0.1 mN∙m (for TS 100 – 50 mN∙m and TS 101 – 100 mN∙m). The executable software controls the system and displays acquired data. It provides accurate peak-to-peak measurement of cogging torque and displays X-Y or polar graphs as well as FFT analysis. ... more information www.magtrol.com

Request for a quote

ZUMBACH ELECTRONIC AG

Switzerland

The processor is used for communication, analysis and display of sensor values for continuous transparency in processes such as: – Wire drawing – Extrusion procedures – In-line or off-line applications – Cutting – Drawing procedures – Tube forming and welding – Taping – Peeling – Centreless grinding – Stranding / assembling – Coating applications Properties Application for specific processor solutions available Processor for monitoring and controlling measuring values Statistical analysis and logging Product recipe management and storage Digital and analogue inputs and outputs Possibility to integrate several sensors Integrated standard host interface FFT/SRL analysis for maximum 4 parameters Zumbach RealTime operating software provides maximum virus protection thanks to embedded software solution.

Request for a quote

ZUMBACH ELECTRONIC AG

Switzerland

The line preheater guarantees successful and high-quality preheating of the conductor for the subsequent extrusion. This improves the adhesion of the cable insulation and the adhesion of the conductor. The preheater is suitable for use in extrusion lines for manufacturing of all types of cables. Properties Inductive heating technology Robust and durable design Material library for fast setup Integrated wire speed sensor that automatically compensates the power output Integrated PoE Ethernet interface Integrated web server in all processor versions Benefits Automated range selection with smart self-monitoring Actual input temperature for control circuit (analogue 0-10 V or serial RS) Optional fine wire guide for very small diameter ranges.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

Results for

Sensor integration - Import exportNumber of results

4 ProductsCountries

Company type