- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- real-time monitoring

Results for

Real-time monitoring - Import export

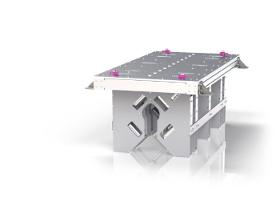

ZUMBACH ELECTRONIC AG

Switzerland

The PROFILEMASTER is a non-contact measuring system for real-time monitoring of continuously manufactured products. It generates a complete log for each production run, while significantly reducing start-up times and scrap. Thanks to its unique concept, accurate and reliable measurements can be guaranteed for virtually any profile shape, regardless of the position and/or twist. An integrated, state-of-the-art software toolbox allows the user to obtain relevant parameters, angles, widths, thicknesses, radii, depths, gaps, diameters or deviations from the nominal value. Profile shapes can be imported directly from DXF files. Properties Real time monitoring of complex profiles Measurements with 4 to 6 cameras Special mode for roundness and polygonality of round products High-precision measurements Detects process problems at an early stage Logging of all production data for QC department Networking capability with a higher level system No post product manual measurements.

Request for a quote

ZUMBACH ELECTRONIC AG

Switzerland

UMAC WALLMASTER systems from ZUMBACH allow in-line measurements, data acquisition and control during the extrusion of a wide range of products, like tubing, pipe, hoses and cables. Cutting edge digital technology (DSP) opens up measuring solutions for each process and product: • Ultra thin walls • Smallest and largest diameters • Multi-layer products • Cable isolations and jackets Special products requiring an off-line QC measurement can now be measured in-line and relevant parameters monitored continuously. The diameter can also be measured in a combination with the ultrasonic measurement with certain transducer holder. In addition, UMAC WALLMASTER systems provide for real-time QC data, process monitoring, trending, SPC data, statistical charts etc.

Request for a quote

ZUMBACH ELECTRONIC AG

Switzerland

The BENDCHECK system is suitable for in-line production optimization in the steel and metal industry. The measuring solution enables in-line quality assurance in the production of tubes and rods and eliminates the need for complex manual straightness measurements. Properties: Synchronous real-time scan to monitor bending of the product 3 to 5 non-contact measuring stations with 1 to 3 measuring axes Direct integration into the existing production process Constant quality assurance, also after the straightening process Recording of statistics, ensuring traceability Time savings thanks to automatic measurement control Continuous measurement without slowing down the production process Replaces manual measurements by means of off-line stations Optional measurement of head and tail bending with additional measuring stations. Benefits: Cutting-edge optics & laser scan technology Maximum accuracy & stability Extremely high sampling rate Comprehensive quality control

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

Results for

Real-time monitoring - Import exportNumber of results

3 ProductsCountries

Company type