- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- food industry

Results for

Food industry - Import export

KASAG SWISS AG

Switzerland

Special equipment, production aid, pipeline construction, assembly In a dynamic market environment, new constructions, modifications, production expansions and the potential for process optimization not fully exploited, represent constant challenges, even in the food industry. The experts at KASAG support and accompany you in all your investment and maintenance projects in the food technology with design, engineering, manufacturing, pipeline construction and assembly. In addition, you will have access to KASAG’s knowhow in the areas of energy recovery (renewable energy) and pressure vessel construction. With KASAG as your partner, you can count on specialists on location.

Request for a quote

KASAG SWISS AG

Switzerland

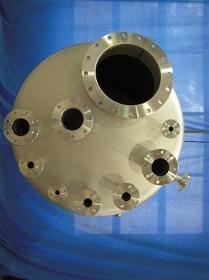

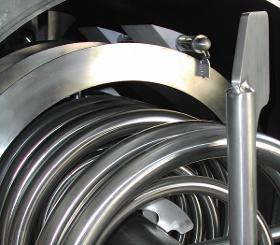

The task of storing liquids hazardous to water or to their processing must be handled responsibly. In the building of the corresponding process containers, storage tanks, stainless steel containers, different factors must be taken into consideration. They are designed according to regulations, such as PED (AD-2000, SVTI, EN13445) or according to special standards, such as the Basel chemical standard BN76 and manufactured in stainless steel. Process containers and storage tanks have half-pipe coils, jackets or laser-welded structures (pillow plates) for heating and cooling purposes. KASAG is the competent place if you are looking for replacement, modification, extension or reconstruction of complete tank plants. We will share your responsibilities.

Request for a quote

KASAG SWISS AG

Switzerland

In order to prepare the fruit base, vegetables, jam, marmalade, jelly and sauces, horizontal or vertical mixing systems are used. Mixers are vital for attaining the highest product quality. The main aim is to ensure consistent mixing and temperature distribution by applying the lowest possible shear force on the pieces of the product. Since it is possible to thereby realise short process times along with the qualitatively high-value process apparatuses, KASAG has the ideal mixing technology for you. For the horizontal mixers, KASAG also has a special bearing and mechanical seal that has been tried and tested over many years. On an ongoing process to develop our mixing system and the bearing and mechanical seals further to attain optimal product quality and to enable smooth operation.

Request for a quote

KASAG SWISS AG

Switzerland

Fat melting systems The KASAG fat melting system are compact systems for melting fat blocks from palm kernel fat, palm oil fat, coconut fat and concentrated butter. The liquid grease thereby gained is kept in the collecting tray at a specified temperature to be used in the respective production process. Size and design are determined by KASAG according to the requirements of the customer. Fat oil station KASAG fat oil station is an extension of the fat melter and is used to mix the ingredients into the liquid fat. The plants are installed on a base frame with levelling feet. All built components are ready for connection. The hot-water treatment and regulation is conducted via a tempering unit or connection to an existing hot-water network.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

Results for

Food industry - Import exportNumber of results

4 ProductsCountries

Company type