- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- magnets

Results for

Magnets - Import export

STL SYSTEMS AG

Switzerland

The digital magnetometers of the DM Series are based on STL’s unrivalled high resolution ADC technology with 32 bit resolution and 26 bit dynamic range. The magnetometers use fluxgates as their magnetic sensitive elements and have integrated DXS. As a result of consequent digital signal processing, our magnetometers are quasi ideal sensors with digitally corrected geometry and temperature errors. The DM Series provides a measurement range of up to 1 mT, with an ultra precise digitization taking place immediately after the sensor output. All magnetometers measure the 3 orthogonal field components with a maximum sample rate of 10 kHz and offer very low intrinsic noise from 60 pT/√Hz @ 1 Hz down to 6 pT/√Hz @ 1 Hz. The software also offers the total field as an extra virtual channel. Typical error sources like axes misalignment, scaling, offset and phase errors are eliminated to the greatest possible extent due to its consequent digital signal conditioning strategy.

Request for a quote

STL SYSTEMS AG

Switzerland

Our coil systems are specially designed to generate very large magnetic fields in 1 to 3 dimensions. Every system essentially consists of 2 units: The coil system and the current control system to set the coil currents. The systems can be used for calibration, to compensate external fields, to generate specific magnetic fields, magnetic gradients etc. Our specification scope ranges from: - Frequency ranges: DC to 4 MHz, - Field ranges: from a few microtesla to 200 millitesla - Homogenity ranges: 1%, also over large volumes with small coil sizes - Field stabilities up to a few ppm FS - Size range from a few cm to more than 200 m - Actively compensated for environmental changes or uncompensated (optional) - Generating both magnetic fields and magnetic gradients with or without compensation - Magnetic far field drop off: r-3 to r-11

Request for a quote

STL SYSTEMS AG

Switzerland

STL offers the earth magnetic field simulator (EMFS) which can be used for worldwide simulation of the earth magnetic field. Earth Magnetic Field Simulators (EMFS) are typically being installed in a bay area or river estuary as well as artificial harbours. The EMFS System is used for calibration of the onboard degaussing system (OBDS) and Navy vessel's preparation for any operation missions and the dedicated simulation of the magnetic field in the area of mission. Quantity and type of used sensors, sensor array, software and coil system including power sources are always designed in respect of the specific requirements of the customer. STL can supply: - Complete sensor array - Data acquisition system - Control and evaluation software - coil cables and power sources Pricing may vary depending on the requested cable length, available power supply and required magnetic field.

Request for a quote

STL SYSTEMS AG

Switzerland

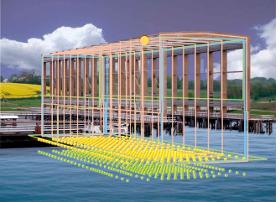

Stationary ship will be treated and ranged by magnetic deperming range in a cage System for the demagnetization of naval ships and subsequent magnetic surveying on a magnetic demagnetization and surveying equipment installed within a cage type frame, with the special feature that the ship is stationary during the entire treatment process similar to the earth magnetic simulator of German Navy. Treatment and magnetic measurement of Navy vessels in combination with time optimzed and area economy lead to a range that combines the advantages of ODMR and HDMR, where all system entities are installed on a frame around the vessel undergoing ranging and treating. Above sketch shwos the ODMR combining simulation and deperming coil system integrated on a cage type building, which can be installed on any harbour or Navy area. Pricing may vary depending on cable length, available power supply and required magnetic field.

Request for a quote

STL SYSTEMS AG

Switzerland

The MD900 is an inductive metal detector for use in garbage sorting. It consists of a high-frequency field generator and a series of probes running transversely to the treadmill, which analyzes the product stream in a location-specific and location-resolved manner. The data for the opening and closing of the valves, which are transmitted in real time via an SPI interface to the valve control in the blowout unit, are calculated. Operation is via an Ethernet interface. All data for configuration during operation (operating mode, sorting program and other parameters) are transmitted via the Modbus / UDP protocol. For updates and error analysis, an independent TCP/IP interface is available. The sensor is connected via 2 connection cables to the blow-out unit.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

Results for

Magnets - Import exportNumber of results

5 ProductsCountries

Company type