- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- co2

Results for

Co2 - Import export

PROMIX SOLUTIONS AG

Switzerland

Promix gas dosing stations for physical foaming have been specially designed and developed to meet the needs of foam extrusion. Promix gas metering technology is characterized by high dosing accuracy, reliability and amazingly simple operation. Promix gas dosing stations meet all the requirements of a modern gas metering system for foam extrusion. These include high-precision mass flow control, process visualization by means of trend charts, operator-definable operating limits, data acquisition, and synchronization of the dosing rate with the extruder output. Implementation in the extruder control system via fieldbus system is also possible. •,Mass flow from 1 g/h up to 20'000 g/h •,Dosing pressure up to 680 bar

Request for a quote

ASCO CARBON DIOXIDE LTD

Switzerland

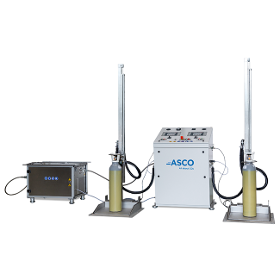

ASCO CO2 Gas Detectors are used to protect personnel wherever CO2 gas or dry ice is used in closed areas, for example during dry ice blasting or when producing dry ice. ASCO offers wallmounted solutions for area monitoring and portable devices for personal protection. ASCO CO2 Gas Detectors ensure continuous and automatic CO2 content measuring in the ambient air using infrared absorption measuring (NDIR). This technology is very troubleresistant to temperature variations or air draughts and therefore measures very accurately. The CO2 gas detectors are very simple to handle and all components are built splash proof.

Request for a quote

ASCO CARBON DIOXIDE LTD

Switzerland

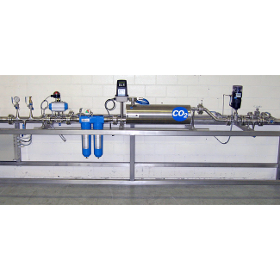

Typically, the ASCO CO2 Gas Dosing System is used together with water desalination plants. The system is equipped with a CO2 pressure reducing valve, filtration unit, CO2 gas flowmeter, CO2 regulating valve, pressure gauges, safety valves and a completely prewired control cabinet. In case of maintenance the system provides a manual bypass line, which also can be monitored by the flowmeter. Herefore, changing a filter cartridge or doing any other service work on the system is quick and easy! As raw and fitting material ASCO uses mainly stainless steel. This makes the system very resistant and extends the products life cycle. easy to install very accurate 4 20 mA output signal robust stainless steel construction no auxiliary equipment like air compressor needed, only power supply is required

Request for a quote

ASCO CARBON DIOXIDE LTD

Switzerland

The ASCO CO2 Flowmeter has been developed to accurately measure CO2 gas flow in closed pipes. The power unit, which supplies 230 V, operates a microprocessor controlled flow computer and one sensor. The ASCO CO2 Flowmeter is a complete system which is supplied fully calibrated and wired and therefore very easy to install.

Request for a quote

ASCO CARBON DIOXIDE LTD

Switzerland

ASCO CO2 Transfer Pumps have steel housings and long life shaft seals. The pumps have hardened steel gears and thrust washers to give long service life. The mechanical seal fitted provides leak free operation. These economical pumps need no lubrication and no daytoday maintenance. A unique design allows parts to adjust automatically for wear. Highest efficiency is maintained for a very long time. Installation is simple as no chain or belt drives or gear reduction motors are required. Pumps can be directly connected to standard speed lowcost electric motors. By simply changing the shaft rotation, pumps can be used to pump in or out through the same piping.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

ASCO CARBON DIOXIDE LTD

Switzerland

The ASCO CO2 Carbonation Tester is used to identify any strange odour and/or taste in CO2. With this simple, easy to use kit you can check the quality of your liquid or gaseous CO2 from bulk tanks or CO2 cylinders. The set includes a CO2 carbonation unit, CO2 cartridge with special inner coating, adaptors made of stainless steel and emptying device for CO2 cartridge and easy instructions. Following the easy, laminated an coloured stepbystep instructions with pictures, a sample of water carbonated is tested. The carbonated water is compared for taste and smell with a noncarbonated sample of the same water. easy handling no calibration required ready for immediate use quick and cheap testing method for gaseous and liquid CO2

Request for a quote

ASCO CARBON DIOXIDE LTD

Switzerland

The ASCO CO2 Gas Purity Tester has been designed to measure the purity of CO2 up to 99.995 % in a quick, easy and reliable way. Essential for bottling plants, breweries, beverage manufacturers and industrial gas companies. The complete kit contains all equipment for a simple, safe and fast CO2 gas purity test and is complete with easy instructions (step by step pictures on a laminated A3 sheet). The ASCO CO2 Gas Purity Tester (stainless steel) can be used either wallmounted or free standing. ASCO CO2 Purity Tester pair of protective gloves protective glasses two plastic containers flexible hose

Request for a quote

ASCO CARBON DIOXIDE LTD

Switzerland

The ASCO CO2 Dew Point Tester reliably indicates the dew point (moisture content) of your CO2. This equipment makes it easy to measure the dew point of liquid and gaseous CO2. A laminated, illustrated stepbystep short instruction sheet in A3 format and a detailed instruction manual are supplied with each tester. The ASCO CO2 Dew Point Tester (stainless steel) can be used either wallmounted or freestanding. easy handling no calibration required ready for immediate use for gaseous and liquid CO2

Request for a quote

ASCO CARBON DIOXIDE LTD

Switzerland

The ideal and reliable highflow CO2 pressure reducing valve for use with CO2 gas or liquide. Constructed in brass (C31) and meehanite (C2K32) with stainless steel trim Abrasion and dirt resistant rubber valve seats Dome loading either from inlet line or separate gas supply Stable and noiseless operation Positive gastight shutoff Highflow contoured passages

Request for a quote

ASCO CARBON DIOXIDE LTD

Switzerland

The ASCO LH900 Liquid CO2 Filling Pump has been developed as an universal unit for filling high pressure CO2 cylinders by weight. Like all ASCO Equipment, the Cylinder Filling and Weighing System is thoroughly factory pretested before despatch. Thanks to the separate control unit, the pump can be placed in a different location. Easy operation Switch on your ASCO LH900 and the unit automatically tares itself to „0“ which will show on the indicator display. After placing a cylinder on the platform, the display will show the accurate tare weight of the cylinder, allowing the operator to check whether the empty cylinder weight is correct. The chosen filling weight can now be set on the display by pressing the relevant keys (when filling the same size of cylinder, the filling weight needs only be entered once). When the desired filling weight is reached and displayed, the solenoid valves of the ASCO LH900 will automatically switch to run the system in bypass.

Request for a quote

ASCO CARBON DIOXIDE LTD

Switzerland

In addition to its standard models, ASCO offers a large number of modern and easy to maintain CO2 vaporisers. In accordance to your requirements, we provide you with a suitable model. In order to meet every customer's need, we have different types, technologies and capacity ranges from 100 to well over 2000 kg/h. ASCO offers following technologies Cold water circulation Electric water bath heater Gas heated water bath Electric Atmospheric Individual solutions Costoptimised applications Reliable operation Minimal maintenance Customised adaptations to local conditions Expert knowhow Outstanding customer service

Request for a quote

ASCO CARBON DIOXIDE LTD

Switzerland

ASCO’s innovative CO2 Gas Recovery Technology turns your vented byproduct gas into profitable CO2. Be it for an alcoholic fermentation process (e.g. breweries, ethanol operations, distilleries or wineries), other industrial sources (e.g. ammonia production or hydrogen reforming) or natural sources, ASCO will find your individual CO2 recovery solution. ASCO’s ByProduct CO2 Gas Recovery System can make this opportunity a reality to those interested in developing a business case and realizing the potential rewards of recovering CO2 gas from these sources. Our systems, manufactured of the highest quality in materials and workmanship, offers extremely low operating costs placing the least OPEX against CAPEX providing a far greater return on investment. Sources ASCO CO2 Gas Recovery Systems are applicable to a variety of sources

Request for a quote

ASCO CARBON DIOXIDE LTD

Switzerland

ASCO’s innovative ASCOSORB CO2 Stack Gas Recovery Technology turns your vent flue gas into a usable and profitable source of CO2. CO2 gas won by an ASCO Stack Gas Recovery System is a byproduct of flue gas production from boilers as well as from other flue gas sources offering an economic CO2 source to any CO2 consumer or reseller. ASCO, as a provider of complete CO2 solutions, offers CO2 Stack Gas Recovery Systems with various capacities. Reliable CO2 source Reliable and economic source of CO2 to the end user as opposed to self burning processes or purchasing liquid CO2 Reduction in energy usage The ASCOSORB Technology brings to the ASCO CO2 Stack Gas Recovery Plant tremendous reduction in total energy usage offering greatly reduced OPEX only approx. 1.3 MWth / MT produced CO2

Request for a quote

ASCO CARBON DIOXIDE LTD

Switzerland

ASCO CO2 Gas Revert Recovery Systems are engineered to efficiently recover the revert CO2 gas from ASCO Dry Ice Pellet and Block Machines which normally direct the revert (flash) gas to the atmosphere. When dry ice is produced the conversion rate from liquid CO2 to dry ice is approx. 4045 %. This means 5560 % is lost to the atmosphere. This conversation rate is a physical fact and therefore, unfortunately, not to change. With a CO2 Revert Recovery System, however, most of the CO2 can be recovered which leads to a final conversion rate of approx. 9095 %. This way, the dry ice production costs are reduced up to 50 %.

Request for a quoteResults for

Co2 - Import exportNumber of results

15 ProductsCompany type