- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- it quality

Results for

It quality - Import export

KOMAX HOLDING AG

Switzerland

The MicroLab 10 enables micrographs to be taken quickly and easily regardless of the location. It covers all relevant processing steps – from cutting and polishing to etching and visualization. The compact carry-case design enables the quality of crimp and splice connections to be assessed with minimum effort and maximum effectiveness. Available in a portable carry-case, the compact MicroLab 10 is designed for contacts and conductors of up to 2.5 mm in diameter. The samples can be quickly clamped in the holder – no re-clamping for all processing steps. The laboratory’s components include autonomous, independent preparation, evaluation and documentation modules. A complete on-site analysis can therefore be performed within a short period of time. A USB digital camera with a microscope is integrated into the lab for visualization purposes and to ensure complete documentation.

Request for a quote

KOMAX HOLDING AG

Switzerland

Seamless quality control is becoming an ever important factor in competition. Micrographs are indispensable in the release of new crimp terminals and tools. The MicroLab 35 micrograph laboratory is a central part of modern quality engineering. MicroLab 35 is designed for the quick creation of micrographs of terminals up to a diameter of 3 mm. The processing time is short thanks to the fully automatic transport system and the reliable technology. The parallel processes allow one micrograph per minute to be created on a continuous basis. The sample is clamped in place quickly with laser support, so the inspection position is determined precisely. There is no re-clamping of samples – the MicroLab 35 cuts and polishes the samples automatically. As soon as the samples arrive at the evaluation unit, they undergo electrolytic cleaning – the micrograph is taken and evaluated.

Request for a quote

KOMAX HOLDING AG

Switzerland

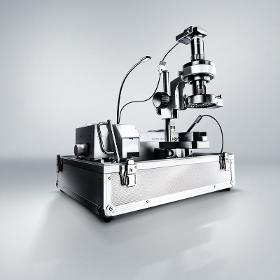

MicroLab 30 is designed for creating micrographs of terminals up to a diameter of 10 mm. Processing can be done in less than thirty seconds thanks to the intuitive control system and the optimized arrangement of the cutting and polishing module. An integrated line laser simplifies the determination of the microsection position. The autonomous preparation, evaluation and documentation modules that are part of the lab operate independently of each other and enable a complete on-site analysis. A standardized holder positions the sample without having to re-clamp it. The concentric arrangement of the saw blade and polishing wheel enable an optimum process sequence. Reproducible micrograph preparation is assured by the two step motors that serve as a multi-axial feed control system. The mobile MicroLab 30 requires very minimal maintenance.

Request for a quote

KOMAX HOLDING AG

Switzerland

Seamless quality control is becoming an ever important factor in competition. Micrographs are indispensable in the release of new crimp terminals and tools. The highly flexible and modular MicroLab 55 micrograph laboratory is a central part of modern quality engineering. The MicroLab 55 micrograph laboratory is designed for the most versatile application ranges and is ideally suited for this purpose. It enables micrographs to be produced for all types of crimps available on the market – both transverse section and longitudinal section. The above applies also to products such as PCBs or housings from outside the automotive sector. Extremely short processing times can be achieved thanks to the optimum arrangement of the individual modules. Reproducible sample preparation is guaranteed to be perfect because the sample does not have to be re-clamped between the individual processing steps.

Request for a quote

KOMAX HOLDING AG

Switzerland

The bt 288 features two twisting lines, making it the perfect solution for efficient wire set processing – even where large quantities are involved. The Komax bt 288 is based on the proven and tested technology of the bt 188 T. With a second twisting line, this semiautomatic twisting machine offers virtually double the production efficiency without any reduction in processing quality. And with its small footprint, it takes up hardly any space at all. The bt 288 calculates the cut length automatically and – in conjunction with the flat gripper option – can be used to twist three or four wires. The intuitive software (operated via touchscreen) enables you to save the twisting parameters.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

KOMAX HOLDING AG

Switzerland

With its extra large mounting surface, the Alpha 356 has room for up to seven processing modules. This machine is ideal if you need increased flexibility or have complex processes. Along with the most frequent standard processes of crimping and seal loading, you can obtain a large variety of processing modules such as: fluxing/tinning, twisting the ends of wires, fitting with insulating sleeves and crimping modules for the widest variety of contacts types, ultrasonic or resistance welding modules. You can integrate customer-specific processing stations easily with the ultra-flexible TopWin software.

Request for a quoteResults for

It quality - Import exportNumber of results

7 ProductsCountries

Company type