- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- surface grinding

Results for

Surface grinding - Import export

OPSIL LTD

Bulgaria

Depending on the customers’ orders, the crystals are being ground on the outside diameter of a diamond peripheral sawing disk. We have got three centre grinders with a total monthly capacity 2000 kg. Maximum ground diameter – Ф200 mm. Accuracy 0.03 mm. Surface roughness - Ra ˂ 0.25.

Request for a quote

TYROLIT - SCHLEIFMITTELWERKE SWAROVSKI AG & CO K.G

Austria

Tyrolit leads in grinding wheels for surface and creep feed grinding, especially in highly porous wheels. Our products' high porosity and low hardness ensure maximum cutting ability and removal rates, even on hard materials. This market leadership is due to the intelligent design of our grinding wheels, tailored to material and workpiece geometry for tight tolerances and perfect surface finish. Grain type, grit size, grade, bond, and structure are adjusted for maximum precision and efficiency. Tyrolit offers a broad range of highly efficient grinding wheels for surface and creep feed grinding, ideal for the turbine industry. Our highly porous, vitrified-bonded abrasives guarantee long tool life, cool grinding, and increased profile retention. Electroplated wheels, primarily used in the turbine industry, provide excellent profile accuracy and maximum process stability, resulting in precise grinding results and lower component costs.

Request for a quote

MARXAM PROJECT

Poland

The grinding services are a surface finishing process that includes every detail that requires the removal of machining allowance and obtaining large classes of surface roughness. For technological reasons and the number of requirements as to the further condition of the surface of the elements, we adjust the metal grinding process to individual customer requirements. Metal grinding is a finishing treatment involving the treatment of surfaces of various shapes with abrasive tools. Grinding allows you to remove burrs (deburring) and roughness, as well as machining allowance. This surface finishing method allows to obtain a surface with low roughness and desired shapes and dimensions with quite high accuracy. Surface grinding is one of the most common methods of surface treatment, for a wide variety of metals, including grinding steel, metal grinding bits, grinding welds, aluminum grinding and many others.

Request for a quote

THOMSON MACHINERY BV

Netherlands

Jung JF520 surface and profile grinding machine in very good condition. Machine No. 1569. Year of construction 1981 - Grinding length max. 600 mm - Sliding width: 200mm - Magnet size: 500x175mm - Grinding wheel dimensions: 250x25x50.8mm Bcspaqsayd8 - Spindle speed: stepless 4200 omw./min. - 380V 4kW - Weight about 2000kg Equipment: - 1 axis digital display, - Flanges - Infinitely adjustable spindle speed - Infinitely variable hydraulic supply in transverse direction - auto lubrication system, - Automatic height feed with rapid traverse - machine books

Request for a quote

ID GROUP

France

bevelled edges to avoid the risk of falling resists sparks from welding and grinding rough antislip surface surface very resistant to weld spatter long life expectancy excellent antifatigue performance thanks to highend 100% nitrile foam

Request for a quote

TYROLIT - SCHLEIFMITTELWERKE SWAROVSKI AG & CO K.G

Austria

Tyrolit serves industries demanding precision and efficiency in double side face grinding. We offer tools that meet the highest standards for precision, performance, and efficiency. With years of experience and innovation, we guarantee the production of plane-parallel functional surfaces of the highest quality without thermal surface damage, even for large grinding allowances and high stock removal volumes. Our tools help achieve the tightest tolerances. Our resin-bonded grinding wheels enable efficient generation of functional surfaces with high evenness and quality. Both face sides can be machined simultaneously, or one side at a time using wheels, segments, rings, or cup wheels. These abrasives offer constant grinding properties, long service life, and a cool grinding finish. Tyrolit also offers diamond grinding tools for ceramic components. Tyrolit's double side face grinding tools combine precision with efficiency. Our experts can help optimize your processes.

Request for a quote

TYROLIT - SCHLEIFMITTELWERKE SWAROVSKI AG & CO K.G

Austria

Tyrolit rondeller enhance its versatility, combining the benefits of various grinding tools in one product without needing special accessories like supporting discs or clamping nuts. Simply start working and enjoy the unique geometry and stud pattern of the rondeller, which offers excellent chip transport, cool grinding, and ergonomic use. The rondeller also guarantee vibration-free operation and optimal adaptation to the workpiece for grinding, deburring, and shaping curved surfaces. Tyrolit offers high-quality rondeller for metals, stone, and PVC. For steel and stainless steel, we recommend grit size 24/36 for high stock removal and grit size 60 for finer surface results. For deburring or grinding nonferrous metals like aluminum, copper, brass, or bronze, our rondeller contain a special bond to prevent clogging. Tyrolit also provides rondeller for professional machining of stone materials and PVC.

Request for a quote

TYROLIT - SCHLEIFMITTELWERKE SWAROVSKI AG & CO K.G

Austria

Diamond grinding tools with VIB-Star core for technical ceramic components. Diamond grinding tools with cushioning plastic core system for machining very hard materials and technical ceramic components. Straight diamond grinding tools in vitrified bond for the machining of ceramic components require special damping, thus VIBSTAR is only available in certain dimensions on request. Damping + low weight Better surface finishes Longer lifetime Improved grinding ratio

Request for a quote

TYROLIT - SCHLEIFMITTELWERKE SWAROVSKI AG & CO K.G

Austria

Tyrolit cup wheels are exceptionally robust and durable, offering high stock removal rates, especially when machining large welding seams or grinding imperfections on exposed concrete surfaces. Our range includes cup wheels for metal, marble, slate, and granite, all identified by a consistent color coding system for easy selection. For metal machining, our cup wheels are designed for steel and stainless steel, perfect for large-area grinding, edge grinding, and bevelling. For stone, our cup wheels remove imperfections on exposed concrete, pre-grind engineered stone and terrazzo slabs, and perform surface grinding on marble, slate, and granite. Cup wheels are designed for use with angle grinders of 178 mm diameter. Smaller machines turn too fast, and larger machines too slow. Always use a special protection cover for safety. Tyrolit cup wheels offer unmatched durability, performance, and ease of use for various materials and applications.

Request for a quote

TYROLIT - SCHLEIFMITTELWERKE SWAROVSKI AG & CO K.G

Austria

Tyrolit centerless grinding wheels can grind workpieces from a few millimeters to several meters in length with maximum precision and cost-effectiveness, ideal for large series of identical parts. Centerless grinding wheels are notably thick compared to their diameter. Special pressing processes, adapted specifications, and sometimes split grinding wheels ensure homogeneous density distribution. Tyrolit offers a complete assortment of grinding wheels, regulating wheels, and dressing tools. Continuous product development guarantees high stock removal, tight tolerances, and fine surface results. Resin-bonded CBN grinding tools with a fiber-reinforced composite carrier body offer up to 80 percent less weight and better absorption properties, enhancing grinding results and tool life. Vitrified-bonded wheels use innovative sintering technology to prevent abrasive grain breakage. Lightweight diamond wheels are available for centerless through-feed grinding, gentle on machine spindles.

Request for a quote

TYROLIT - SCHLEIFMITTELWERKE SWAROVSKI AG & CO K.G

Austria

In precision grinding, maintaining tight tolerances and perfect surface structures is crucial. The demands in this area have increased, challenging both grinding tool manufacturers and producers. Tyrolit meets these requirements through innovations in precision grinding wheels, distinguished by extensive process know-how and pioneering consulting services. We serve a wide range of industries, including tool manufacturing, automotive, steel, turbine, and medical technology, always adhering to the principle: accuracy is key! Tyrolit offers standardized application technology advice and process support at the highest level. Our expert team, with years of experience, provides constant support. Employees across various countries are closely linked with our headquarters in Austria, ensuring qualified technical support for all precision grinding applications, such as external and internal cylindrical grinding, surface and creep feed grinding, or honing.

Request for a quote

OPSIL LTD

Bulgaria

After the surface grinding, the crystal is sliced into wafers with a thickness according to customer’s specifications. Sawing machines with diamond impregnated blade are used for the slicing. We have got 5 sawing machines with a monthly capacity 2500 kg. Maximum diameter Ф152 mm. Wafer thickness up to 80 mm. Slicing accuracy ± 25 microns.

Request for a quoteHASPA GMBH

Germany

We also sell abrasives for all kinds of surface treatment: Grinding, roughing, milling, polishing. Special tools upon request. Systems: - M-quick - K-quick - ATAdisc - corundum(Plus) - zirconium (Z) - carboorundum - fleece rounds - felt rounds - super brade Ask for our abrasive catalogue or send us your detailed inquiry.

Request for a quote

TYROLIT - SCHLEIFMITTELWERKE SWAROVSKI AG & CO K.G

Austria

In every application, Tyrolit fibre discs offer flexibility, high stock removal rates, and easy handling. Our range includes vulcanized fibre discs and eco-friendly natural fibre discs made from jute fibre, used without additional cores. These trimmable discs allow maximum stock removal throughout their service life. The CERABOND X fibre disc excels in high removal rate and longevity. We provide high-quality accessories like supporting discs in various grades to adjust the stock removal rate. Special designs ensure constant air circulation, preventing heat buildup. Fibre discs are clamped onto angle grinders, with Quick-Change versions for mini grinders for hard-to-reach areas. CERABOND technology combines ceramic grain with our unique bond system for lasting aggressiveness and durability, ideal for surface grinding, weld seam removal, rust removal, and deburring. CERABOND X and zirconia alumina discs are available in packs of 50, with a spindle system to prevent bending.

Request for a quote

BEFORT WETZLAR OD GMBH

Germany

At Befort, spherical precision optics pass through the hands of qualified specialists. They work with a sure instinct and stateoftheart technology. The machine processing of each surface is done on CNC grinding and polishing machines. We produce spherical precision lenses from optical glass, quartz glass and radiationresistant materials with diameters from 3 mm to 130 mm and a curvature radius from 1.18 mm to plane. We make individual lens elements, achromatic systems, concave mirrors, cylinder lenses and other precisely fitting glass geometries to suit your specific application.

Request for a quote

GRONBACH

Germany

Gronbach manufactures decorative elements for the automotive industry in interior and exterior areas such as trim strips or trim parts made of aluminium, stainless steel and plastic hybrid technology. Functional components and plastic injection molded parts with a focus on fan wheels and turbines are also essential components of our technologies. As a specialist for surface finishing, you have a wide range of colours (anodising, powder coating), noble shapes and surfaces (brushing, grinding, polishing, blasting) and high-quality individualisation (screen printing, pad printing, under-anodising printing, laser engraving, etching techniques) at your disposal. In addition to the production of individual parts and the manufacture of complex assemblies as well as end products, we also offer you as a system supplier the complete project planning for new developments. Our portfolio includes: Automotive door sills Interior visible parts, e.g. side applications, decorative panels and...

Request for a quote

KEIPER GMBH & CO. KG ANTRIEBS- U. TRANSPORTTECHNIK

Germany

Coatings for movement. Today, the effectiveness of state-of-the-art production lines more than ever before calls for a high degree of specialization. The requirements posed with respect to movable components are rising steadily, just like the performance and calculation of operating time. KEIPER timing belts are finished with high-quality coatings in order to meet the required technical specifications accurately and reliably. Many different types of mechanical processing are available: milling in all directions, profiling, punching for vacuum applications as well as grinding edges and surfaces. Our extensive know-how in combining the right coating and mechanical processing options leads to precisely the specific designs required by our customers.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

ESTIMET SP Z O.O.

Poland

We perform metalworking operations on all types and grades of materials. Our machine park allows us to offer you services: edge processing (chamfering) machining of holes (drilling threading chamfering) surface treatment (wide-belt grinding, shot-blasting) Reduce the need for additional operations, which we will perform for you comprehensively!

Request for a quote

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

Zirconia (ZrO2) Ceramics have the highest toughness and strength at room temperature of all the advanced ceramic materials. At present, it has been widely used in grinding balls, dispersion and grinding media, nozzles, ball valve seats, zirconia molds, micro fan shafts, optical fiber pins, optical fiber sleeves, drawing dies and cutting tools, wear-resistant knives, and other room-temperature resistant Grinding parts and so on. Zirconia is widely used in the fields of the thermal barrier layer, catalyst body, medical treatment, health care, textile, and so on. This dense advanced ceramics material is usually precision ground using conventional diamond cutters and wheels. Machines used for precision grinding include: Surface grinders CNC milling machines Jig grinders Centerless grinders CNC lathes ID grinders

Request for a quote

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

Zirconia (ZrO2) Ceramics have the highest toughness and strength at room temperature of all the advanced ceramic materials. At present, it has been widely used in grinding balls, dispersion and grinding media, nozzles, ball valve seats, zirconia molds, micro fan shafts, optical fiber pins, optical fiber sleeves, drawing dies and cutting tools, wear-resistant knives, and other room-temperature resistant Grinding parts and so on. Zirconia is widely used in the fields of the thermal barrier layer, catalyst body, medical treatment, health care, textile, and so on. This dense advanced ceramics material is usually precision ground using conventional diamond cutters and wheels. Machines used for precision grinding include: * Surface grinders * CNC milling machines * Jig grinders * Centerless grinders * CNC lathes * ID grinders

Request for a quote

ORGECO SPOL. S R.O.

Slovakia

Our company specializes in manufacturing sheet metal components according to individual customer requirements and specifications. We utilize state-of-the-art technologies, including laser cutting, CNC precise bending of sheet metal, robotized welding workstations, robotized grinding workstation, and CNC center for rounding and grinding the surface of sheet metal. These advanced tools enable us to deliver products of the highest quality and precision. Whether it's intricate designs or specific dimensions, our technological capabilities allow us to efficiently and reliably meet even the most demanding customer requirements.

Request for a quote

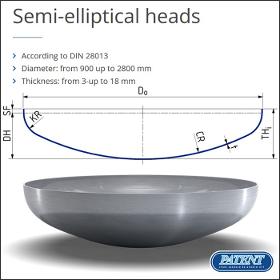

PATENT KFT.

Hungary

Elliptical heads (DIN28011) can be manufactured in stainless steel only. Flanging, bevelling, surface treatment, grinding and polishing, pickling, surface protection and nozzle cut-outs according to customers' requirements. Contact us, ask for a quote! Our staff will be happy to provide you with full information. Acronyms of the technical data: D = outer bottom diameter R = Dish radius s = Wall thickness H = Overall internal height without straight flange h = Height of straight flange

Request for a quote

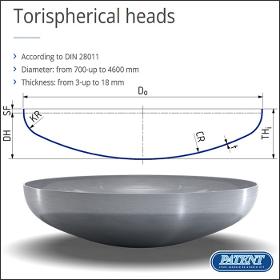

PATENT KFT.

Hungary

Torispherical heads (DIN28011) can be manufactured in stainless steel only. Flanging, bevelling, surface treatment, grinding and polishing, pickling, surface protection and nozzle cut-outs according to customers' requirements. Contact us, ask for a quote! Our staff will be happy to provide you with full information. Acronyms of the technical data: Do = outer bottom diameter Di = inner bottom diameter CR = crown radius KR = knuckle radius SF = straight flange height DH = depth of head THi = full inner bottom height t = wall thickness

Request for a quote

STALEVAR COMPANY LLC

United Kingdom

The hot rolled steel circle is produced at Ukrainian factories, it is an excellent material for the manufacture of a wide range of products produced by the mechanical method on lathes and cutting machines, metal structures , supports, and other products. The steel circle is in demand in mechanical engineering, manufacturing, construction. It is used for making bushings, cylinders, locks, guides, rods, grids, dumbbells, swings, horizontal bars, lattices, washers, linings, pins and other cylindrical products, seamless pipe . Hot rolled steel circle GOST 2590 88, its standard dimensions length from 4 to 6.3 m, thickness from 10 mm to 330 mm. One of the varieties of round products is a calibrated circle produced by the method of cold drawing, grinding, polishing the surface of the product, and the compliance of surface dimensions to microns, which does not require further mechanical processing. You can contact us by mail - marketing@stalevar.com or by phone +380675624220.

Request for a quote

LASEST (LASMEDTECH LLC)

Russia

Er YAG Active LASEST module is widely used for most ablative procedures in aesthetic medicine. The radiation wavelength is 2940 nm, which corresponds to the maximum peak of water absorption, so the depth of direct optical radiation penetration into the skin of this laser module is only 0.01 – 0.1 mm, which guarantees very high accuracy and the absence of side effects like with more “hard” ones CO2 laser. The Er YAG Active laser module can operate in a wide range from ultrashort (from 100 μs) to ultralong (50 ms) pulses depending on the selected mode or technique. An ultrashort pulse allows “cold” surface grinding without heating the lower layers of the skin, which is ideal for correcting agerelated manifestations, scars and postacne. The ultralong impulse promotes the deepest possible laser heating, due to which stimulation of own collagen cells, structural changes in the dermal layer occurs, improving skin texture, smoothing scars, reducing agerelated skin changes

Request for a quote

KB ROLLER TECH KOPIERWALZEN GMBH

Germany

The requirements: long life good thermal capacity of silicones non-stick top coatings precise tolerances for runout, diameter and coating thicknesses without surface grinding

Request for a quote

KB ROLLER TECH KOPIERWALZEN GMBH

Germany

The requirements: highly precise tolerances without surface grinding extremely thin silicone coating layers (in picture: 0.6 mm) high silicone thermal conductivity (in picture: > 0.8 W/mK) anti-adhesive, thin top coatings (in picture: 30µm PFA)

Request for a quoteResults for

Surface grinding - Import exportNumber of results

50 ProductsCountries

Category

- Grinding - machine tools (9)

- Adjustment - machine tools (8)

- Abrasive discs (4)

- Cold rolled sections (2)

- Cutting - steels and metals (2)

- Bending machine tools (1)

- Biomedical equipment (1)

- Ceramics, industrial (1)

- Ceramics, refractory (1)

- Conveyor belts (1)

- Grinding - steels and metals (1)

- Industrial resin coatings (1)

- Metallurgy - machinery and installations (1)

- Optical instruments (1)

- SMALL METAL PARTS (1)

- Sheet metal and strips, tinplate (1)

- Sheets, rubber (1)

- Steel & Metals (1)

- Steels and metals - machining (1)