- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- supervision systems

Results for

Supervision systems - Import export

EKINEX

Italy

Ekinex® delégo is a supervision system which allows to control and monitor a domotic plant using a mobile device (smartphone and tablets) equipped with Apple iOS or Android operating system. The supervision system is based on a dedicated hardware platform running a simple and intuitive configuration web interface. Through this interface it is possible to perform the plant’s setup in few steps, by directly importing the ETS project of the domotic plant: in this way, once the import phase is completed, the user can start to control and monitor all the domotic functions of the delégo application.

Request for a quote

TPF - CONSULTORES DE ENGENHARIA E ARQUITETURA, S.A.

Portugal

Design Analysis, Review and Verification Audits, Surveys, Technical Inspections and Due Diligence Licensing, Contracting and Procurement Project Management and Coordination Management, Coordination and Construction Supervision Special Geotechnical Consultancy Services

Request for a quote

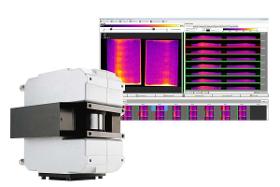

FLUKE PROCESS INSTRUMENTS GMBH

Germany

The TIP900 system is a comprehensive thermal imaging and noncontact profiling system designed to supervise the temperature of wallboards coming out of the oven. It uses an infrared thermal imager to continuously scan the entire board surface temperatures and allows the detection in real time of moisture and density variations inside each board. The powerful TIP900 software provides sophisticated data integration, visualization and event analysis, and offers users a complete solution of real-time monitoring, detection and traceability. It also analyzes and provides optimal oven dryer profile balance. The detailed wallboard quality maps, the historical temperature trend charts and the images can be seen locally at the operator workstation or remotely. All data is stored in the LogViewer database for complete process visibility and long term traceability. TIP900 System Software Detailed continuous board quality monitoring (100% of all board images are archived)

Request for a quote

EUROLASER GMBH

Germany

Loading and unloading during cutting process - increased system duty Easier accessibility of the pieces produced by moving the material support Increasing efficiency by minimising downtime Easy handling Automatic table shift after cutting process possible System is not encapsulated - Robot assembly possible (24/7 - operation) New material is located on the top shuttle table - thereby no material remaining is falling on the new material. Shuttle Table System automatic (STA) Table shift at the touch of a button Process starts automatically after cutting is finished Time saving by optimised processes Minimising supervision of the laser system Additional manual handling possible Snapping table module in after the shuttle process prevents incorrect handlings Of course, the Shuttle Table System is still available as a mere manual version.

Request for a quote

KONCAR - ELECTRONICS AND INFORMATICS LTD.

Croatia

KONreg S1000 with its compact design, small dimensions and integrated power converter is ideal solution for brushless and small synchronous generators, motors and motor-generator sets. It supports a number of communication protocols and in itself has built several communication interfaces. In conjunction with embeded software allows regulation up to 25A (40A, 10s) and 375Vdc. The main control loop is an automatic voltage regulator with adjustable PID controller. In addition to that in regulator are implemented other additional control functions such as power factor controller or cos (φ) regulator. Field current regulator of PI type is built in as a stand-by regulator. Synchronization function is also implemented in regulator. System allows easy adjustment of all parameters, supervision of all signals inside system and waveform capture (record) through a personal computer and the HMI device.

Request for a quote

SIGNODE DENMARK APS

Denmark

The shrink wrap machine type Combi Flex, where hood application and shrinking take place in one space-saving unit, was introduced to the world market by Lachenmeier back in 1982. The film hood is fed from the top of the machine, blown up like a balloon and in this way stretched to the largest possible extent, after which it is applied over load. After application, the film hood is shrunk by mains of heat and is effectively secured for transport. Essential when shrink wrapping loads is the bottom shrinking, where load and pallet are kept tightly together as one unit. One of the most significant advantages of the Lachenmeier shrink wrapping machine is that all four burners have separate automatic speed controlled motors, ignition systems, supervision systems, etc. In case of variations in product dimensions, the heat distribution can be adjusted automatically to each single product.

Do you sell or make similar products?

Sign up to europages and have your products listed

Results for

Supervision systems - Import exportNumber of results

6 ProductsCountries

Company type