- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- super alloys

Results for

Super alloys - Import export

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

Silicon Nitride (Si3N4) is 60% lighter than steel but strong enough to survive some of the most demanding applications in a variety of industries. This lightweight, high-strength ceramic material is used as an alternative to stainless steel, super alloys, tungsten carbides and first-generation ceramics such as Al2O3 and ZrO2. It offers excellent thermal shock resistance and high fracture toughness, compatibility with nonferrous metal melts, and improved structural reliability compared to other ceramic materials. Silicon Nitride (Si3N4) Characteristics: 1. Good thermal shock resistance 2. Creep resistance 3. Low density 4. High fracture toughness 5. High hardness and wear resistance 6. Electrical resistivity

Request for a quote

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

Factory Custom Silicon Nitride Thermal Substrate for High Power Radiator Silicon Nitride (Si3N4) is 60% lighter than steel but strong enough to survive some of the most demanding applications in a variety of industries. This lightweight, high-strength ceramic material is used as an alternative to stainless steel, super alloys, tungsten carbides and first-generation ceramics such as Al2O3 and ZrO2. It offers excellent thermal shock resistance and high fracture toughness, compatibility with nonferrous metal melts, and improved structural reliability compared to other ceramic materials. Silicon Nitride (Si3N4) Characteristics: >Good thermal shock resistance >Creep resistance >Low density >High fracture toughness >High hardness and wear resistance >Electrical resistivity

Request for a quote

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

Silicon Nitride (Si3N4) is 60% lighter than steel but strong enough to survive some of the most demanding applications in a variety of industries. This lightweight, high-strength ceramic material is used as an alternative to stainless steel, super alloys, tungsten carbides and first-generation ceramics such as Al2O3 and ZrO2. It offers excellent thermal shock resistance and high fracture toughness, compatibility with nonferrous metal melts, and improved structural reliability compared to other ceramic materials. Silicon Nitride (Si3N4) Characteristics: 1 Good thermal shock resistance 2 Creep resistance 3 Low density 4 High fracture toughness 5 High hardness and wear resistance 6 Electrical resistivity

Request for a quote

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

Silicon Nitride (Si3N4) is 60% lighter than steel but strong enough to survive some of the most demanding applications in a variety of industries. This lightweight, high-strength ceramic material is used as an alternative to stainless steel, super alloys, tungsten carbides and first-generation ceramics such as Al2O3 and ZrO2. It offers excellent thermal shock resistance and high fracture toughness, compatibility with nonferrous metal melts, and improved structural reliability compared to other ceramic materials. Silicon Nitride (Si3N4) Characteristics: >Good thermal shock resistance >Creep resistance >Low density >High fracture toughness >High hardness and wear resistance >Electrical resistivity

Request for a quote

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

Ceramic Si3N4 Silicon Nitride Tube Silicon Nitride (Si3N4) is 60% lighter than steel but strong enough to survive some of the most demanding applications in a variety of industries. This lightweight, high-strength ceramic material is used as an alternative to stainless steel, super alloys, tungsten carbides and first-generation ceramics such as Al2O3 and ZrO2. It offers excellent thermal shock resistance and high fracture toughness, compatibility with nonferrous metal melts, and improved structural reliability compared to other ceramic materials. Silicon Nitride (Si3N4) Characteristics: 1 Good thermal shock resistance 2 Creep resistance 3 Low density 4 High fracture toughness 5 High hardness and wear resistance 6 Electrical resistivity

Request for a quote

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

Silicon Nitride (Si3N4) is 60% lighter than steel but strong enough to survive some of the most demanding applications in a variety of industries. This lightweight, high-strength ceramic material is used as an alternative to stainless steel, super alloys, tungsten carbides and first-generation ceramics such as Al2O3 and ZrO2. It offers excellent thermal shock resistance and high fracture toughness, compatibility with nonferrous metal melts, and improved structural reliability compared to other ceramic materials. Silicon Nitride (Si3N4) Characteristics: >Good thermal shock resistance >Creep resistance >Low density >High fracture toughness >High hardness and wear resistance >Electrical resistivity

Request for a quote

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

Silicon Nitride (Si3N4) is 60% lighter than steel but strong enough to survive some of the most demanding applications in a variety of industries. This lightweight, high-strength ceramic material is used as an alternative to stainless steel, super alloys, tungsten carbides and first-generation ceramics such as Al2O3 and ZrO2. It offers excellent thermal shock resistance and high fracture toughness, compatibility with nonferrous metal melts, and improved structural reliability compared to other ceramic materials. Silicon Nitride (Si3N4) Characteristics: 1 Good thermal shock resistance 2 Creep resistance 3 Low density 4 High fracture toughness 5 High hardness and wear resistance 6 Electrical resistivity

Request for a quote

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

Silicon Nitride Ceramic Bar: Silicon Nitride (Si3N4) is 60% lighter than steel but strong enough to survive some of the most demanding applications in a variety of industries. This lightweight, high-strength ceramic material is used as an alternative to stainless steel, super alloys, tungsten carbides and first-generation ceramics such as Al2O3 and ZrO2. It offers excellent thermal shock resistance and high fracture toughness, compatibility with nonferrous metal melts, and improved structural reliability compared to other ceramic materials. Silicon Nitride (Si3N4) Characteristics: >Good thermal shock resistance >Creep resistance >Low density >High fracture toughness >High hardness and wear resistance >Electrical resistivity

Request for a quote

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

Silicon Nitride (Si3N4) is 60% lighter than steel but strong enough to survive some of the most demanding applications in a variety of industries. This lightweight, the high-strength ceramic material is used as an alternative to stainless steel, super alloys, tungsten carbides, and first-generation ceramics such as Al2O3 and ZrO2. It offers excellent thermal shock resistance and high fracture toughness, compatibility with nonferrous metal melts, and improved structural reliability compared to other ceramic materials. When extreme conditions like these push equipment to its limits, Silicon Nitride (Si3N4) industrial ceramics deliver high performance where other materials fail. Typically, Heavy-duty diesel engines. Jet engine igniters. Oil wells thousands of feet underground. Applications for silicon nitride include: Foundries Electronics Oil & Gas Automotive Aerospace

Request for a quote

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

Silicon Nitride (Si3N4) is 60% lighter than steel but strong enough to survive some of the most demanding applications in a variety of industries. This lightweight, the high-strength ceramic material is used as an alternative to stainless steel, super alloys, tungsten carbides, and first-generation ceramics such as Al2O3 and ZrO2. It offers excellent thermal shock resistance and high fracture toughness, compatibility with nonferrous metal melts, and improved structural reliability compared to other ceramic materials. When extreme conditions like these push equipment to its limits, Silicon Nitride (Si3N4) industrial ceramics deliver high performance where other materials fail. Typically, Heavy-duty diesel engines. Jet engine igniters. Oil wells thousands of feet underground. Applications for silicon nitride include: Foundries Electronics Oil & Gas Automotive Aerospace

Request for a quote

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

Silicon Nitride (Si3N4) is 60% lighter than steel but strong enough to survive some of the most demanding applications in a variety of industries. This lightweight, the high-strength ceramic material is used as an alternative to stainless steel, super alloys, tungsten carbides, and first-generation ceramics such as Al2O3 and ZrO2. It offers excellent thermal shock resistance and high fracture toughness, compatibility with nonferrous metal melts, and improved structural reliability compared to other ceramic materials. When extreme conditions like these push equipment to its limits, Silicon Nitride (Si3N4) industrial ceramics deliver high performance where other materials fail. Typically, Heavy-duty diesel engines. Jet engine igniters. Oil wells thousands of feet underground. Applications for silicon nitride include: Foundries Electronics Oil & Gas Automotive Aerospace

Request for a quote

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

Silicon Nitride (Si3N4) is 60% lighter than steel but strong enough to survive some of the most demanding applications in a variety of industries. This lightweight, the high-strength ceramic material is used as an alternative to stainless steel, super alloys, tungsten carbides, and first-generation ceramics such as Al2O3 and ZrO2. It offers excellent thermal shock resistance and high fracture toughness, compatibility with nonferrous metal melts, and improved structural reliability compared to other ceramic materials. When extreme conditions like these push equipment to its limits, Silicon Nitride (Si3N4) industrial ceramics deliver high performance where other materials fail. Typically, Heavy-duty diesel engines. Jet engine igniters. Oil wells thousands of feet underground. Applications for silicon nitride include: Foundries Electronics Oil & Gas Automotive Aerospace

Request for a quote

LBI

France

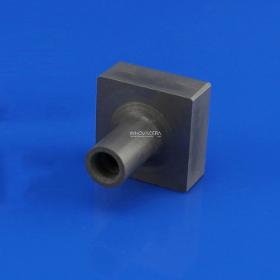

We manufacture rough or fully machined feeding tube for nickel processing furnaces in nickel super alloy

Request for a quote

AMETEK SPECIALTY METAL PRODUCTS

United States

Our NORSOK-approved Super Duplex alloy 2507 tubes (UNS 32750) are custom-engineered for the most aggressive subsea and downhole oil and gas applications. Advantages include: NORSOK-approval Made to order in specialist non-standard sizes Superior strength and corrosion resistance Short lead times Small batch sizes With 80 years engineering expertise, we specialise in manufacturing corrosion resistant Super Duplex tubes for the increasing hostile temperature and operating environments. Greater Corrosion Resistance Than Standard Duplex Grades Super Duplex stainless like S32750, is a mixed microstructure of austenite and ferrite (50/50) which has improved strength over ferritic and austenitic steel grades. The main difference is that Super Duplex has a higher molybdenum and chromium content which gives the material greater corrosion resistance than standard duplex grades. Please note that we have a minimum order value of £10,000.

Request for a quote

AMETEK SPECIALTY METAL PRODUCTS

United States

Because of its strength, unique density and corrosion resistance, titanium has found applications in many industries. For high quality tubing products, it’s often a better substance to use than competing materials like stainless steels or super alloys. Titanium tubes are light weight and exceptionally corrosion and heat resistantThe density of titanium is about 60 per cent of that of steel- or nickel-based alloys giving significant weight savings in aerospace structures. The tensile strength is better than that of austenitic or ferritic stainless steels. Titanium is exceptionally corrosion resistant and exceeds the resistance of stainless steels in most environments. The metal is non-magnetic too, and has good heat transfer properties, with a melting point higher than steel alloys. Titanium is easily worked. Please note that we have a minimum order value of £10,000.

Request for a quote

PVA INDUSTRIAL VACUUM SYSTEMS GMBH

Germany

VSG systems offer a poven and economic solution for the inductive melting of metals or alloys under vacuum or protective gas atmosphere and subsequent casting. Applications: The VSG furnaces can be universally employed for melting and casting under high vacuum or different gas atmospheres in the laboratory or production, e.g. alloying, degassing, purification melting, re-melting processing of noble metals highly pure, highly alloyed steel. • Processing of: ◦noble metals ◦ processing of highly pure, highly alloyed steel ◦ High temperature resistant materials on Fe- Ni- Co- basis ◦ Solar-silicon and other special material ◦ Special- / super alloys

Request for a quote

ELECTRONICS INTERNATIONAL

Italy

ASUS ROG Strix NVIDIA GeForce RTX 3090 White OC Edition Gaming Graphics Card (PCIe 4.0, 24GB GDDR6X, HDMI 2.1, DisplayPort 1.4a, White Color Scheme, Axial-tech Fan Design, 2.9-Slot, Super Alloy Power About this item NVIDIA Ampere Streaming Multiprocessors: The building blocks for the world’s fastest, most efficient GPU, the all-new Ampere SM brings 2X the FP32 throughput and improved power efficiency. 2nd Generation RT Cores: Experience 2X the throughput of 1st gen RT Cores, plus concurrent RT and shading for a whole new level of ray tracing performance. 3rd Generation Tensor Cores: Get up to 2X the throughput with structural sparsity and advanced AI algorithms such as DLSS. Now with support for up to 8K resolution, these cores deliver a massive boost in game performance and all-new AI capabilities. OC edition: Boost Clock 1890 MHz (OC mode)/1860 MHz (Gaming mode) Limited white edition for themed gaming rigs.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

Results for

Super alloys - Import exportNumber of results

17 ProductsCompany type