- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- suction nozzles

Results for

Suction nozzles - Import export

R&S PAPIERVERARBEITUNGS-GMBH

Germany

You will find: crevice nozzle in two lengths and pipe diameters Upholstery nozzle, with thread lifter in different pipe diameters Suction brush, with swivel joint in various pipe diameters Suction hose, complete with connections and hand tube Telescopic tube, various telescopic tubes in different tube diameters for vacuum cleaners of well-known manufacturers

Request for a quote

NIRO PRÄZISIONSTECHNIK GMBH

Germany

Niro Präzisionstechnik specializes in the manual mechanical processing of stainless steel thin sheets up to 4 mm. Our specialty are funnels, composite shapes, reductions and transitions, for example from round to square. All connections are welded while avoiding the inclusion of oxygen, and the weld seams are made invisible through careful polishing. The workpieces are machined free of tension and distortion with uniform wall thicknesses. We only process non-rusting materials such as V2A and V4A stainless steel, titanium alloys and aluminum. Our production conditions allow the manufacture of products for clean room applications such as those used in the pharmaceutical industry, medical technology and in the food industry. Suction devices Ring suction Downpipes Nozzles machine parts Assembly

Request for a quote

BALLERSTAEDT & CO. OHG

Germany

SEAMIAUTOMATIC SEALING DEVICE suitable for the sealing of all sorts of plastic and glass containers. 1. foil application device PolySeal Vario DIS (left hand side) electro-pneumatic stepless pressure regulation stepless manual height adjustment with height scale foil dispensing with 2 spot pre-sealing removable pre-sealing plates heat protection shield vacuum suction nozzle roller guide with running slide foil magazine for stackable pre-cut sealing lids VARIOTRONIC, control unit for the regulation of temperature, sealing time and pressure 2. sealing device PolySeal Vario PN (right hand side) electro-pneumatic stepless pressure regulation stepless manual height adjustment with height scale sealing head heating block, swingable, anodised aluminium hollowed out sealing die heat protection shield container holder VARIOTRONIC, control unit for the regulation of temperature, sealing time and pressure

Request for a quote

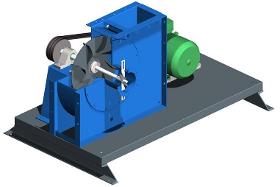

RIPPERT ANLAGENTECHNIK GMBH & CO. KG

Germany

For the even chopping of continuous strips. Cutting fans Our cutting fans chop continuous strips, such as those found in the furniture industry, for example. 4 blades and counter blades located in the suction nozzle ensure even chopping. Subsequently, the material is fed via a pressure pipeline to the place of destination.

Request for a quote

K-TECH ELECTRONIC VERTRIEBS GMBH

Germany

The vacuum packgaing machine AZ450ES from AIRZERO is working with a suction nozzle compared to vacuum chamber machines. The main advantages are Since only the bag and not the entire chamber is emptied, the process is faster. Lower gas consumption when gassing (only the bag is gassed and not the entire chamber). The gas is blown into the bag in a targeted and controlled manner. No limitation of the bag length by the chamber. Bar goods can therefore also be processed. Compact standalone device. double sealing (up/down) ejektorvakuum pump (air pressure required) gas flushing vacuum creation timer controlled, sensor controlled digital vakuum display 4 programms can be saved housing of stainless steel suitable for cleanroom

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

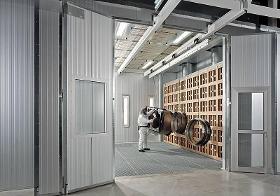

RIPPERT ANLAGENTECHNIK GMBH & CO. KG

Germany

Spray walls and spray booths with dry separation via cartons. For lower utilisation times or overspray quantities RES dry spray booth For lower utilisation times or smaller overspray quantities, spray systems with dry separation offer a meaningful alternative to water-sprinkled systems. The Rippert modular spraying system type RES enables individual adaptation to the respective case of need. The filter system of the RES dry spray wall consists of individual square cardboard boxes. A sheet metal frame serves as a support structure for the filter box. In order to save costs, there is a possibility to vary the individual filter boxes in the spray booth, without exchanging all of the filter elements. Function The overspray is caught by the exhaust air stream and fed to the filter. The solids are filtered out here, while the cleaned exhaust air is blown out into the open air by the fan. Versions The basic version consists of a wall with a two-fold filter stage. Paper filter boxes form the first filter stage. A glass fibre fine filter arranged directly behind it represents the second filter stage. The attached radial fan is equipped with spark protection in the suction nozzle as well as an explosion-proof motor. The spray booth can additionally be equipped with removable or fixed side and ceiling panels. The RES dry spray booth is available in galvanised sheet metal or in stainless steel. Advantages Cleaning / maintenance The spray wall is designed such that the filter elements can be exchanged with little effort in a very short time. Once it is saturated, the filter box is removed from the sheet metal frame and disposed of in an environmentally-friendly manner.

Request for a quote

RIPPERT ANLAGENTECHNIK GMBH & CO. KG

Germany

Spray walls and spray booths with dry separation via pre-filters and fine filters. Spray walls and spray booths with dry separation For lower utilisation times or overspray quantities, spraying systems with dry separation offer a meaningful alternative to water-sprinkled systems. The Rippert modular spraying system type RTS enables individual adaptation to the respective case of need. Function The overspray is caught by the exhaust air stream and fed to the filter. The solids are filtered out here, while the cleaned exhaust air is blown out into the open air by the fan. Versions The entire spray wall and the drip tray are made of galvanised sheet steel. The basic version consists of a wall with a two-fold filter stage. The attached radial fan is equipped with spark protection in the suction nozzle as well as an explosion-proof motor. The first filter stage is formed by a paper filter or a baffle plate filter, consisting of two rows of galvanised sheet metal lamellae arranged one behind the other. A glass fibre fine filter arranged directly behind it represents the second filter stage. The spray wall can additionally be equipped with removable or fixed side and ceiling panels. Each version is also available with floor suction pan, available with an integrated 2-stage filter and grating cover. Accessories In addition, the spray wall can be equipped with various accessories from the Rippert product range, such as explosion-proof lights, energy-saving flaps, turntables, etc. We recommend the installation of a supply air system for the replacement of the exhausted air. Cleaning / maintenance The spray wall is designed such that the filter elements can be exchanged with little effort in a very short time. For faster cleaning, baffle plate filters should by sprayed with a release agent (e.g. strippable varnish) before being put into operation. Underfloor paint mist extraction With dry separation, consisting of a support structure with attached paper filter, grating cover and a suction duct with air quantity adjustment.

Request for a quote

ECKOLD GMBH & CO. KG

Germany

Automated punching plants are particularly economical for large quantities, offering excellent process safety. The ECKOLD range of punching machines includes automated punching units as well as portable and hand-held tools, thus catering for virtually any punching task. After a detailed evaluation of your punching task, we devise a solution that is not only economical but also perfectly adapted to match your requirements and workpiece specifications. This offer includes: • Pneumatic punching frame for fixing a cover • Stationary or robot-guided • Round hole, D = 3.5 • Integrated suction nozzle for scraps • Punching inserts • Assembly condition/interfaces: drilling pattern at c-frame • Connectable to cylinder, feed ejectors, initiators Tools are not included in the scope of delivery. They must be chosen separately, based on the actual task. Other drive types on request. Contact us for a customised offer!

Request for a quote

BALLERSTAEDT & CO. OHG

Germany

SEAMIAUTOMATIC SEALING DEVICE suitable for the sealing of all sorts of plastic and glass containers. 1. foil application device PolySeal Vario DIS (left hand side) • electro-pneumatic • stepless pressure regulation • stepless manual height adjustment with height scale • foil dispensing with 2 spot pre-sealing • removable pre-sealing plates • heat protection shield • vacuum suction nozzle • roller guide with running slide • foil magazine for stackable pre-cut sealing lids • VARIOTRONIC, control unit for the regulation of temperature, sealing time and pressure 2. sealing device PolySeal Vario PN (right hand side) • electro-pneumatic • stepless pressure regulation • stepless manual height adjustment with height scale • sealing head heating block, swingable, anodised aluminium • hollowed out sealing die • heat protection shield • container holder • VARIOTRONIC, control unit for the regulation of temperature, sealing time and pressure

Request for a quote

OPTIMA CONSUMER GMBH

Germany

Filling: - Suction nozzles or suction bell for reduced dust emergence during filling is optional - Filling and sealing systems coordinated to the product - Synchronization interface for the bottling plant - Vibrating the containers under the filling positions for product compaction and optimal utilization of the container's volume Dosing/Weighing: - 200 parameter sets can be stored in the recipe memory - Alternative volumetric or gravimetric positioning - Gross weight check - Identifying and adjusting for fluctuations in the bulk weight - High-precision positioning for constant filling weight/volume - Different dosing technologies are available - Volumetric dosing with auger filler Further information: www.optima-packaging.com/en/packaging-solutions/filling-and-closing-machine-optima-fc2

OPTIMA CONSUMER GMBH

Germany

Filling: - Filling process in protective gas for reduced oxygen contents in the packaging is optional - Suction nozzles or suction bell for reduced dust emergence during filling is optional - Filling and sealing systems coordinated to the product Dosing/Weighing: - 100% tare/gross weighing - 200 parameter sets can be stored in the recipe memory - Identifying and adjusting for fluctuations in the bulk weight - High-precision positioning for constant filling weight/volume - Different dosing technologies are available - Volumetric dosing with auger filler Further information: www.optima-packaging.com/en/packaging-solutions/filling-and-closing-machine-optima-cfl-40

OPTIMA CONSUMER GMBH

Germany

Filling: - Filling process in protective gas for reduced oxygen contents in the packaging is optional - Suction nozzles or suction bell for reduced dust emergence during filling is optional - Filling and sealing systems coordinated to the product Dosing/Weighing: - 100% tare/gross weighing - 200 parameter sets can be stored in the recipe memory - Identifying and adjusting for fluctuations in the bulk weight - High-precision positioning for constant filling weight/volume - Different dosing technologies are available - Volumetric dosing with auger filler Further information: www.optima-packaging.com/en/packaging-solutions/filling-and-closing-machine-optima-cfl-5

«ROBOTKOMPLEKT» LLC (DKR GROUP)

Russia

Dry and wet cleaning of the interior/trunk. Vacuum cleaner Elsea, singe/duplex with post lighting and suction sensors. Hoses and crevice nozzles. Possibility of payment with coins and loyalty cards.

Request for a quoteResults for

Suction nozzles - Import exportNumber of results

14 ProductsCountries

Company type