- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- subcontract shrink wrapping

Results for

Subcontract shrink wrapping - Import export

HUGO BECK MASCHINENBAU GMBH & CO. KG

Germany

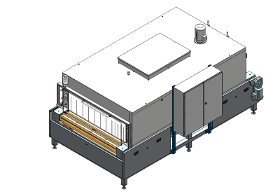

Items that have initially been bagged using a machine from Hugo Beck often need to be shrunk so as to ensure a tight-fitting film and the perfect packaging finish to meet the highest standards. Adapted for each packaging system, we supply the appropriate shrink tunnel in all sizes and performance ranges for the production of high-quality shrink packaging. As such, we manufacture shrink tunnels in a number of versions, with a variety of rods and chains that operate like a link mesh belt. Textile mesh belts are also possible for very light products. In each case, the length of the shrink tunnel depends on the speed of packaging and on the film material selected. State-of-the-art air ducting and heat recovery ensure efficient energy use, helping us to contribute to both protection of the environment and reducing energy costs. The decision on whether to use a shrink tunnel with circulating air or convection principle is defined depending on the individual product application of the customer.

Request for a quote

HUGO BECK MASCHINENBAU GMBH & CO. KG

Germany

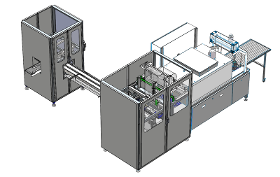

The servo X 800 are the most flexible and powerful of film packaging machines in the horizontal large-format segment – and all this with maximum modularity. They can be configured individually and thus meet all requirements. Whether chain infeed or infeed conveyor, servo X 800 machines win over with their continuous packaging process and no stop-and-go, meaning dead time is not an issue when sealing. Besides high performance, this enables extremely tight-fitting and precise packaging with a saving in film of up to 15 %. This ensures that the film packaging‘s excellent appearance is unrivalled.

Request for a quote

FERPLAST SNC

Italy

TF 6540 FA SHRINK WRAPPER MACHINE WITH PNEUMATIC PUSHER TF 6540 FA semiautomatic sleeve sealing machine with pneumatic pusher suitable for shrink packing both single object and combined. Shrink packing machine is used in many industrial sectors such as printing, pharmacy, floor, beverage, beer etc. and it’s suitable for all kinds of shrink films such as PVC, POF, PP, PE etc The machine is equipped with motorized reel holder and stabilizer plate for light parcels. After the process of sealing & cutting, the products enter the shrink tunnel BS 5540 M automatically.

Request for a quote

ZAPPE PACKAGING TECHNOLOGY GMBH & CO. KG

Germany

The Entry-level "QUICK-SHRINK" Model – versatile and reliable.

Request for a quote

ZAPPE PACKAGING TECHNOLOGY GMBH & CO. KG

Germany

Dimensionally Stable Protectioneven during Transport

Request for a quote

ZAPPE PACKAGING TECHNOLOGY GMBH & CO. KG

Germany

The full wrap packaging from Zappe ensures a perfect wrapping - for perfect sealing and schrinkage of goods of all kinds.

Request for a quote

ZAPPE PACKAGING TECHNOLOGY GMBH & CO. KG

Germany

The full wrap packaging from Zappe ensures a perfect wrapping - for perfect sealing and schrinkage of goods of all kinds.

Request for a quote

SOLICOM S.A.

Luxembourg

Bi-directional shrinkage: his is determined during production by the choice of the extruder and the blow ratio. As a result, the shrinkage properties and the mechanical properties of a film are determined. VeriSafe ® films have similar contraction strength, both vertically and horizontally. This is unique on the market and gives our film unique features: - by heating - resulting in a perfect clamping of the film and also a permanent shrinkage force for a long time and therefore a super resistance to gusts of wind (guarantee up to 10 Beaufort). Welding properties: are determined by the raw materials used, as well as the capacity of the extruder. The welding is very important and must be permanent for long time. Welding's which dissolve over time weaken the tension of the film and thus also the stability of the work. Puncture resistance: this is determined by the blow grade of the extrusion and by the chemical composition.

Request for a quote

SOLICOM S.A.

Luxembourg

Bi-directional shrinkage: his is determined during production by the choice of the extruder and the blow ratio. As a result, the shrinkage properties and the mechanical properties of a film are determined. VeriSafe ® films have similar contraction strength, both vertically and horizontally. This is unique on the market and gives our film unique features: - by heating - resulting in a perfect clamping of the film and also a permanent shrinkage force for a long time and therefore a super resistance to gusts of wind (guarantee up to 10 Beaufort). Welding properties: are determined by the raw materials used, as well as the capacity of the extruder. The welding is very important and must be permanent for long time. Welding's which dissolve over time weaken the tension of the film and thus also the stability of the work. Puncture resistance: this is determined by the blow grade of the extrusion and by the chemical composition.

Request for a quote

SOLICOM S.A.

Luxembourg

Bi-directional shrinkage: his is determined during production by the choice of the extruder and the blow ratio. As a result, the shrinkage properties and the mechanical properties of a film are determined. VeriSafe ® films have similar contraction strength, both vertically and horizontally. This is unique on the market and gives our film unique features: - by heating - resulting in a perfect clamping of the film and also a permanent shrinkage force for a long time and therefore a super resistance to gusts of wind (guarantee up to 10 Beaufort). Welding properties: are determined by the raw materials used, as well as the capacity of the extruder. The welding is very important and must be permanent for long time. Welding's which dissolve over time weaken the tension of the film and thus also the stability of the work. Puncture resistance: this is determined by the blow grade of the extrusion and by the chemical composition.

Request for a quote

SOLICOM S.A.

Luxembourg

Bi-directional shrinkage: his is determined during production by the choice of the extruder and the blow ratio. As a result, the shrinkage properties and the mechanical properties of a film are determined. VeriSafe ® films have similar contraction strength, both vertically and horizontally. This is unique on the market and gives our film unique features: - by heating - resulting in a perfect clamping of the film and also a permanent shrinkage force for a long time and therefore a super resistance to gusts of wind (guarantee up to 10 Beaufort). Welding properties: are determined by the raw materials used, as well as the capacity of the extruder. The welding is very important and must be permanent for long time. Welding's which dissolve over time weaken the tension of the film and thus also the stability of the work. Puncture resistance: this is determined by the blow grade of the extrusion and by the chemical composition.

Request for a quote

SOLICOM S.A.

Luxembourg

Bi-directional shrinkage: his is determined during production by the choice of the extruder and the blow ratio. As a result, the shrinkage properties and the mechanical properties of a film are determined. VeriSafe ® films have similar contraction strength, both vertically and horizontally. This is unique on the market and gives our film unique features: - by heating - resulting in a perfect clamping of the film and also a permanent shrinkage force for a long time and therefore a super resistance to gusts of wind (guarantee up to 10 Beaufort). Welding properties: are determined by the raw materials used, as well as the capacity of the extruder. The welding is very important and must be permanent for long time. Welding's which dissolve over time weaken the tension of the film and thus also the stability of the work. Puncture resistance: this is determined by the blow grade of the extrusion and by the chemical composition.

Request for a quote

SOLICOM S.A.

Luxembourg

Bi-directional shrinkage: his is determined during production by the choice of the extruder and the blow ratio. As a result, the shrinkage properties and the mechanical properties of a film are determined. VeriSafe ® films have similar contraction strength, both vertically and horizontally. This is unique on the market and gives our film unique features: - by heating - resulting in a perfect clamping of the film and also a permanent shrinkage force for a long time and therefore a super resistance to gusts of wind (guarantee up to 10 Beaufort). Welding properties: are determined by the raw materials used, as well as the capacity of the extruder. The welding is very important and must be permanent for long time. Welding's which dissolve over time weaken the tension of the film and thus also the stability of the work. Puncture resistance: this is determined by the blow grade of the extrusion and by the chemical composition.

Request for a quote

SOLICOM S.A.

Luxembourg

Bi-directional shrinkage: his is determined during production by the choice of the extruder and the blow ratio. As a result, the shrinkage properties and the mechanical properties of a film are determined. VeriSafe ® films have similar contraction strength, both vertically and horizontally. This is unique on the market and gives our film unique features: - by heating - resulting in a perfect clamping of the film and also a permanent shrinkage force for a long time and therefore a super resistance to gusts of wind (guarantee up to 10 Beaufort). Welding properties: are determined by the raw materials used, as well as the capacity of the extruder. The welding is very important and must be permanent for long time. Welding's which dissolve over time weaken the tension of the film and thus also the stability of the work. Puncture resistance: this is determined by the blow grade of the extrusion and by the chemical composition.

Request for a quote

SOLICOM S.A.

Luxembourg

Bi-directional shrinkage: his is determined during production by the choice of the extruder and the blow ratio. As a result, the shrinkage properties and the mechanical properties of a film are determined. VeriSafe ® films have similar contraction strength, both vertically and horizontally. This is unique on the market and gives our film unique features: - by heating - resulting in a perfect clamping of the film and also a permanent shrinkage force for a long time and therefore a super resistance to gusts of wind (guarantee up to 10 Beaufort). Welding properties: are determined by the raw materials used, as well as the capacity of the extruder. The welding is very important and must be permanent for long time. Welding's which dissolve over time weaken the tension of the film and thus also the stability of the work. Puncture resistance: this is determined by the blow grade of the extrusion and by the chemical composition.

Request for a quote

SOLICOM S.A.

Luxembourg

Bi-directional shrinkage: his is determined during production by the choice of the extruder and the blow ratio. As a result, the shrinkage properties and the mechanical properties of a film are determined. VeriSafe ® films have similar contraction strength, both vertically and horizontally. This is unique on the market and gives our film unique features: - by heating - resulting in a perfect clamping of the film and also a permanent shrinkage force for a long time and therefore a super resistance to gusts of wind (guarantee up to 10 Beaufort). Welding properties: are determined by the raw materials used, as well as the capacity of the extruder. The welding is very important and must be permanent for long time. Welding's which dissolve over time weaken the tension of the film and thus also the stability of the work. Puncture resistance: this is determined by the blow grade of the extrusion and by the chemical composition.

Request for a quote

SOLICOM S.A.

Luxembourg

Bi-directional shrinkage: his is determined during production by the choice of the extruder and the blow ratio. As a result, the shrinkage properties and the mechanical properties of a film are determined. VeriSafe ® films have similar contraction strength, both vertically and horizontally. This is unique on the market and gives our film unique features: - by heating - resulting in a perfect clamping of the film and also a permanent shrinkage force for a long time and therefore a super resistance to gusts of wind (guarantee up to 10 Beaufort). Welding properties: are determined by the raw materials used, as well as the capacity of the extruder. The welding is very important and must be permanent for long time. Welding's which dissolve over time weaken the tension of the film and thus also the stability of the work. Puncture resistance: this is determined by the blow grade of the extrusion and by the chemical composition.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

GUANGZHOU WORLDE PACKAGING MACHINERY CO.,LTD

China

Automatic L Sealer Shrink Wrap Machines are widely used in the assembly line of mass production and packaging. It is suitable for products of different widths and heights. It uses an electronic eye to detect products when they pass through the conveyor. After a product passes the sealing arm, the seals fully enclose the product in shrink film. After the seal, products continue to pass into the shrink tunnel. The shrink tunnel has recirculating heat to shrink the film to the product evenly. Fully wrapped products exit the tunnel, and the film is conformed tightly to the product. Using the original "OMRON" digital temperature controller with built-in PID function, the temperature of the sealing knife is extremely sensitive and accurate, and can be set at will. The sealing knife itself also has an automatic protection function, which can effectively prevent miscut packaging, and has an automatic alarm function, which greatly improves the safety of the operator.

GUANGZHOU WORLDE PACKAGING MACHINERY CO.,LTD

China

Automatic Sleeve Shrink Wrap Machine is made to wrap heavy products with thick film.The finished packaging has two open ends on each side which are referred to as "bullseyes". Standard products packaged with a shrink bundling machine include firewood, canned goods, cases of water bottles, metal products, tool cases, and more. The machine can carry out two-row, three-row, four-row shrink packaging with or without bottom support,like 10 bottles (1 × 10), (2 × 5), 9 bottles (3 × 3), 12 bottles (3 × 4), 15 bottles (3 × 5), 24 bottles (4 × 6). Using worm gear reducer, products feeding and film feeding smooth without jitter. Adopt "Siemens" "PLC" program controller to realize the integration of machine, electricity and gas.Using worm gear reducer, products feeding and film feeding smooth without jitter.Specially designed sealing knife, the sealing line is firm, not cracked, and not easy to stick to the knife.The frequency converter controls the transmission speed.

Results for

Subcontract shrink wrapping - Import exportNumber of results

20 ProductsCompany type