- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- strain sensors

Results for

Strain sensors - Import export

BURSTER PRÄZISIONSMESSTECHNIK GMBH & CO KG

Germany

Situations often occur in practice in which it is necessary to place a measuring amplifier immediately in the neighborhood of the sensor in order to be able to access a standard signal there. In this way, long distances to the evaluating electronics can be covered. This task can ideally be performed by the 9236 in-line measuring amplifier. With its high degree of protection (IP67) its singlechannel version can be integrated into the application even in the tough environment outside the switch gear cabinet. — Automatic production machinery — Laboratory measurements — Integration into customer‘s circuit boards — Field measurements Features: — Operates with up to 4 measuring channels — Voltage output 0 to ± 5 V / 0 to ±10 V — Protected against reverse connection and short-circuit — Also available as circuit board without housing — Simple configuration using DIP switch — High degree of protection up to IP67

Request for a quote

BURSTER PRÄZISIONSMESSTECHNIK GMBH & CO KG

Germany

The 7270 TRANS CAL can run on standard or rechargeable batteries for portable use or from an external power supply. The handy model 7270 digital indicator supports load cells, pressure sensors and torque sensors based on strain gages. The 14 mm high display shows the current measured value. The TARE function allows any base load that may be present to be zeroed. The clear, well organized control structure enables quick and easy configuration of the TRANS CAL. The 7270 is equipped with a charge state indicator. Features: — Easy to operate - For all load cells, pressure sensors and torque sensors based on strain gages — Tare function - Excellent value for money - Built-in charge controller

Request for a quote

BURSTER PRÄZISIONSMESSTECHNIK GMBH & CO KG

Germany

This miniature force sensor was optimised with respect to its height and is, at only 3.4 mm, the lowest known sensor with strain gage technology. Hardly higher than the diameter of its connection cable, it can also be housed in conditions where space is limited. Along with its minimal geometry, the force sensor is also particularly light. It has a high resonance frequency to follow quickly changing load alternations. Despite its extreme miniaturisation, in its application it remains completely robust and suitable for industry, not only with regard to the highly flexible cable connections or the full welding of sensors for the measurement ranges ≥ 0 … 10 N. The miniature compression force sensors are flat, cylindrical discs with covered bottoms. The central load application button for taking on compression forces is an integrated part of the top, which is the sensor‘s membrane.

Request for a quote

BURSTER PRÄZISIONSMESSTECHNIK GMBH & CO KG

Germany

The newly developed sensor PROFIBUS module model 9221 is predestined for the integration of various analog sensor output signals into complex, net worked and peripheral automation structures. This module finds its fields of application in the industrial automation technology as well as the test rig technology based on its secure and reliable transfer mode, the fast transfer speed and its simple construction. The inputs (e.g. PLC signal gauge) and outputs in addition to the external control allow a zero compensation by trigger via proximity switch or fast alerting on passing of set point values. Industrial type connection and mounting techniques enable the user the adaption and integration in the existing mechanical and electrical environment. The excellent quality of measurement together with the high grade capture of mean values also enable the application in research and development. The use of standardized PROFIBUS protocols makes the connection an easy task for the programmer.

Request for a quote

BURSTER PRÄZISIONSMESSTECHNIK GMBH & CO KG

Germany

Due to their small dimensions and sturdy construction, these miniature compression load cells made of stainless steel can be used in a wide range of industrial applications and in laboratories. This compression load cell is easy to handle and its installation is uncomplicated. Its small size makes it perfect for use in very restricted structures for both static and dynamic compression force measurements. The miniature compression load cell model 8415 is a flat cylindrical disc, the bottom of which is closed with a cover. The load application button for receiving the compression forces is an integrated part of the sensor. A strain gage full bridge is applied in the gauging member of the measuring element. This produces bridge output voltage directly proportional to the measured force. The small diameter of the sensors results in high rigidity and a short measurement range. The measuring force has to be applied centrically and free from lateral forces.

Request for a quote

BURSTER PRÄZISIONSMESSTECHNIK GMBH & CO KG

Germany

The force measuring chain has been developed for applications where the requirements for precision are not the primary focus, but rather where an economical purchase price and simple functionality are the key criteria. The sensor‘s strain gauge technology allows both static and dynamically changing forces to be measured. The large display means that the force acting on the sensor can be read easily. The four integrated threaded holes allow the sensor to be integrated quickly and easily into existing production and assembly equipment. Typical applications include: —Testing the strength of welded joints —Sports medicine —Monitoring the clamping force of hose connections The body of the sensor is a flat, cylindrical disk, into which a domed force application knob is integrated. It is important that the force is applied axially to the center of the sensor.

Request for a quote

BURSTER PRÄZISIONSMESSTECHNIK GMBH & CO KG

Germany

Load cell model 8417 measures the tension or compression force between both axially mounted metric exterior threads on the cylindrical sensor housing. Forces are only applied to the threadings, which are especially long, to accommodate counter nuts and must not be affected by external influences such as bending, lateral force or torsion. Any contact with units affixed to the sensor housing - even on the front - must be avoided. The measurement element is a membrane perpendicular to the axis of the sensor with a strain gage full bridge applied to the inner surface, which requires stable excitation with a rated value of approx. 1 mV/V. The connection cable is led radially out of the housing through a sleeve which is used for strain relief. FEATURES: —Measuring ranges from 0 ... 10 N to 0 ... 5 kN —Very small dimensions —Made of stainless steel —Rugged construction —Simple screw mounting —burster TEDS optionally available

Request for a quote

BURSTER PRÄZISIONSMESSTECHNIK GMBH & CO KG

Germany

This high precision torque sensor is designed for both static and dynamic measurements on non-rotating applications. It is particularly suitable for torque measurements on, for instance, extremely small electrical actuating drives and micro-mechanical actuator elements, or for measuring reaction torques e.g. on micro-motors. The high accuracy of measurement also makes this sensor ideal for use as a reference in many fields of industrial manufacture as well as laboratory research and development projects. Not containing any rotating parts, it requires no maintenance if properly used. The strain-gage based sensor’s modular design allows precise configuration for the desired application. With the integrated amplifier option, the sensor directly supplies a voltage signal of 0 ... ±10 V that is proportional to the torque. The sensor can be configured via the micro-USB interface, providing access to, for example, a filter frequency setting, averaging, and a tare function.

Request for a quote

BURSTER PRÄZISIONSMESSTECHNIK GMBH & CO KG

Germany

This force measurement chain was developed for applications where a low cost solution is more important than achieving high levels of accuracy. The sensors strain gauge technology allows the measurement of static and dynamic forces. The load cell is also designed for applications that provide only little space due to its compact design. These properties, together with the sensors dust protection, make the measuring chain suitable for a wide range of applications, such as Industrial manufacture Manufacture of customized machinery Geological investigations Motor vehicle engineering Commercial agriculture Bridge building The body of the sensor is a flat, cylindrical disk, into which a domed force application knob is integrated. It is important that the force is applied axially to the center of the sensor. The domed form, however, minimizes the effect of a force that is not exactly axial.

Request for a quote

BURSTER PRÄZISIONSMESSTECHNIK GMBH & CO KG

Germany

This high-precision torque sensor is designed for both static and dynamic measurements on non-rotating parts. The 10mm diameter throughhole can be used to feed parts such as cables or Bowden cables through the sensor. The mounting flanges contain threaded holes and through-holes so that the sensor can be fitted at either end. With no rotating parts, this sensor needs no maintenance when used correctly. The modular design of this strain-gage sensor allows precise configuration for the desired application. With the integrated amplifier option, the sensor directly supplies a voltage signal of 0 ... ± 10 V that is proportional to the torque. The sensor can be configured via the micro-USB interface, providing access to, for example, a filter frequency setting, averaging, and a tare function. With the USB option, in addition to the voltage output, the measurement function is available via USB as well.

Request for a quote

BURSTER PRÄZISIONSMESSTECHNIK GMBH & CO KG

Germany

This high-precision torque sensor can be used to perform both static and dynamic measurements on non-rotating parts. The internal and external square drive design make this sensor especially easy to fit in existing or new screw-fitting applications. Quality assurance and monitoring of screw-fastening tools are just two applications that can take full advantage of sensor features such as USB port, built-in amplifier and side-load absorbing bearings. With no rotating parts, this sensor needs no maintenance when used correctly. Available accessories include mounting brackets and flange adapters, which enable quick, easy and practical integration of the sensor into existing or newly developed setups and test benches. The strain-gauge based sensor’s modular design allows precise configuration for the desired application. With the integrated amplifier option, the sensor directly supplies a voltage signal of 0 ... ± 10 V that is proportional to the torque.

Request for a quote

BURSTER PRÄZISIONSMESSTECHNIK GMBH & CO KG

Germany

The new strain gage amplifier with IO-Link interface enables digitalization of the measurement technology right from the sensor. Its compact design and high degree of protection allow the instrumentation amplifier to be used practically anywhere in the field. Strain gage sensors typically have an output voltage of a few millivolts. In industrial environments, e.g. in the vicinity of electric motors or frequency converters, interference can affect the measurement result when transmitting analog signals. This is reliably avoided using the new strain gage amplifier with IO-Link interface. The analog link between the sensor and instrumentation amplifier is kept as short as possible, the standardized IO-Link communication is fully digital and interference-free. The amplifier is powered directly via the IO-Link interface – a standardized 5-wire cable with M12 socket. Strain gage sensors can be connected via a 4-pin M8 connector.

Request for a quote

BURSTER PRÄZISIONSMESSTECHNIK GMBH & CO KG

Germany

The amplifier module model 9243 is used wherever measurement signals from strain gauges, potentiometric sensors or DC/DC sensors have to be converted into standard signals. Simply by mounting on conventional DIN-mount rails, it is possible to position the amplifier module on location, in the proximity of the sensor. Especially for rough environments a IP65 version is available. The broad auxiliary power range and the choice between AC or DC permits operation on standard power supplies used in switch gear cabinets. A highly precise reference voltage source is built-in for calibration purposes. A calibrating shunt can also be connected via two separate terminals. This permits deliberate detuning of a strain gauge sensor for calibration or merely to check the measuring chain.

Request for a quote

BURSTER PRÄZISIONSMESSTECHNIK GMBH & CO KG

Germany

The SENSORMASTER 9163 covers a wide range of applications in which process values need to be measured, displayed, analyzed and transferred to higher-level control systems. Typical applications include measuring geometric values in production, for instance differential measurements, or testing material properties in the laboratory. The measured values can be transferred via USB, RS232 or analog output. Features: — For force, pressure or torque measurements using strain gauge sensors — For position or angle measurement using potentiometric or DC/DC sensors — For temperature measurement using Pt 100 sensors or thermocouples — Optional multi-channel model — Optional Profibus or serial interface — 0.1 % measurement accuracy plus sensor-specific linearization — Range of mathematical functions (e.g. differential measurement) — OK/NOK feedback on multi color display and via 4 alarm limit outputs — High sampling rate (500/sec.)

Request for a quote

ESCOM ENHANCED SOLUTIONS

Turkey

Traditional in-pipe pressure sensors, including strain gauge pressure transducers and capacitive pressure sensors, have been essential in various industries for monitoring pressure variations. However, they present several drawbacks. These conventional sensors rely on wired connections for data transmission and power supply, necessitating complex and extensive cabling infrastructure. Cable trays and platforms must be installed to accommodate wiring, increasing costs and architectural requirements. Over time, cables are susceptible to deterioration, leading to signal loss, inaccurate measurements, and potential safety hazards. Regular maintenance is essential to address these issues, adding to operational expenses. Furthermore, the dependence on external power sources or batteries results in additional maintenance and environmental concerns related to battery disposal.

Request for a quote

MEGAPROJECTS BV

Netherlands

Bluetooth connection automatic data sync to mobile app stores historical dta supports up to 10 users 4 precision strain gauge sensors led display

Request for a quote

MAGTROL

Switzerland

LB Series Load Measuring Pins can be used alone or as part of a complete measurement system. Magtrol offers a wide range of Load-Force-Weight Transducers in various executions and accuracy classes and our Load Monitoring Units (LMUs) constitute an ideal safe measurement system which continuously checks for overloads and short circuits. MAGTROL Load Measuring Pins are used to measure load and force and provide overload protection. The pins are mounted into machines in place of normal shafts and fitted with strain gauges, allowing them to produce a signal proportional to the measured load. Manufactured in Switzerland, Magtrol’s LB 2XX Series Load Pins are rugged with high resistance stainless steel and tight construction, designed specifically for use in harsh industrial environments. Available in several standard ranges from 2.5 kN to 1250 kN, these highly ergonomic pins can be used for either new or refitted installations and are adaptable to various conditions.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

MAGTROL

Switzerland

MAGTROL offers a wide range of Load-Force-Weight Transducers with optional integrated electronics or Load Monitoring Units (LMU) with B.I.T.E. functions creating an ideal measurement system which continuously checks for overloads and short circuits. Idealy for use on Safety Applications according to ECE-R10, ISO 13849-1 : CAT4 & PLe and IEC 62061 : SIL3 (LE 6XX SERIES); ISO 13849-1 : CAT2 & PLd and IEC 62061 : SIL2 (LE 4XX SERIES) Magtrol Load Measuring Pins are used to measure load and force, and provide overload protection. The pins are mounted into machines in place of normal shafts and fitted with strain gauges, allowing them to produce a signal proportional to the measured load. Manufactured in Switzerland, Magtrol’s LE Series Load Measuring Pins are rugged with high resistance stainless steel and tight construction. Available in several standard ranges from 2.5 kN to 1 250 kN. .... more information www.magtrol.com

Request for a quote

MAGTROL

Switzerland

Magtrol's new PSD hand-held indicator is a stand-alone unit powered by 3 AA batteries or via USB. It is very compact (~160 x 80 x 50 mm) and can be easily carried and used on a civil engineering site, in a research & development office or laboratory as well as in production shop. Its case is ergonomic, waterproof (IP54) and protected by a rubber shock absorber. It is suitable to any type of strain gauge transducers, being a load cell, a load pin or a reaction torque sensor. The internal amplifier can process signal range of ±0.3 ... 5 mV/V. The new PSD Portable Display is very flexible and complies with the highest specification in terms of accuracy (0.01%) and measurement frequency (1600/s). It allows to store up to 16 programmable measurement ranges which can be configured either directly on the unit or via its USB interface and dedicated software (included). Multiple force or torque transducers can be connected for which actual data as well as the ... read more: www.magtrol.

Request for a quote

PAIBON DEVELOPMENT CO.,LTD

China

High precision strain gauge sensors system

Request for a quote

MAGTROL

Switzerland

With its compact, bearingless, maintenance-free design, the new TF Torque Flange Sensor from Magtrol brings many appealing advantages to torque measurement applications. The TF’s high torsional rigidity supports direct mounting on the machine shaft or flange, avoiding the use of couplings on one side. This allows easy integration into a test system, shortens the overall length of the test bench and reduces costs. Based on strain-gauge technology, the TF Sensor’s precise telemetry system enables highly accurate signal transmission. A signal amplifier mounted in the measuring flange amplifies the measuring signal, modulates it to high frequency and transmits it inductively (via the HF transmitter) to the receiver. In the receiver, the digitized torque signal is transformed into an analog output signal of ±10 VDC. Rotational speed can be measured and converted to a TTL output signal with the optional speed pickup. more info www.magtrol.com

Request for a quote

MAGTROL

Switzerland

Magtrol’s TS In-LineTorque Sensors provide extremely accurate torque and speed measurement. Each model has an integrated conditioning electronic module providing 0VDC to ±5VDC (±10VDC) torque output through an 8-pole connector, as well as a USB interface which can be directly connected to a computer. The sensor is delivered with software allowing easy connection and data acquisition. A speed encoder provides a minimum of 360PPR (Pulse Per Revolution) in Tach A, Tach B and Index reference Z (1PPR). Magtrol Torque Sensors are very reliable, providing high overload protection, excellent long-term stability and high noise immunity. TSSeries sensor models are strain gauge-based measuring systems with imbedded telemetry signal transmission. Three LED lights allow a visual check of the sensor status by color code. The sensor is powered by 24VDC (12-32VDC) through its connector. TARE & B.I.T.E. (Built-In Test Equipment) can be activated by either software or input from the 8-pole connector.

Request for a quote

PAIBON DEVELOPMENT CO.,LTD

China

High precision strain gauge sensors system Tempered glass platform:205x165x4mm Glass silkscreen, two colors printing. Any patterns or colors is optional . Max capacity / Division:5kg/1g,3kg/1g Unit:g,oz, lb:oz,ml LCD display size:54x21mm Touch button with tare function Auto off function Overload and low battery indication Power :1x3V CR2032 lithium battery Product size:205x165x18mmmm

Request for a quote

AMETEK SPECIALTY METAL PRODUCTS

United States

HPM ® 270 Nickel is the highest purity Nickel. The controlled low impurity level provides uniform and repeatable mechanical, electrical, and magnetic properties. The material has excellent corrosion resistance with high thermal and electrical conductivities. A high thermal coefficient of electrical resistance makes it suitable for strain gauges, temperature sensors, and electronic components. The alloy can be formed by all conventional cold forming methods, and can be joined by resistance welding, brazing and soldering. The corrosion resistance is generally very good in most mediums, although, it is subject to intergranular embrittlement by sulfur compounds above 315°C Available Sizes: HPM ® 270 Nickel is available from Hamilton Precision Metals as strip product in thicknesses from 0.0005” to 0.020” (0.0127 mm to 0.508 mm) in widths up to 12.0” (304.8 mm). It is available as foil as thin

Request for a quote

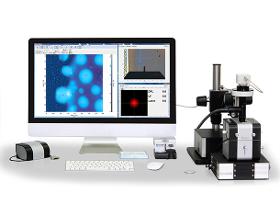

NT-MDT LLC

Russia

AFM holds a strong positions in scientific research as is used as a routine analytical tool for physical properties characterization with high spatial resolution down to atomic level. Solver Nano is the best choice for scientists who are need a single instrument that is an affordable, robust, userfriendly and professional tool. Solver Nano is designed by the NTMDT SI team that also created High Performance Systems like NTEGRA, NEXT II and NTEGRA Spectra II which have been proven in the scientific community through many key publications. Solver Nano is equipped with a professional 100 micron CL (closed loop XYZ) piezotube scanner with low noise capacitance sensors. Capacitance sensors in comparison with strain gauge and optical sensors have lower noise and higher speed in the feedback signal. The CL scanner is controlled by a professional workstation and software. These capabilities enable all of the basic AFM techniques in compact SPM design.

Request for a quote

KYNIX SEMICONDUCTOR HONG KONG LIMITED

Hong Kong

The AD8223ARMZ-R7 Instrumentation Amplifier is a highly reliable, single-channel amplifier, designed to provide high-sensitivity signal conditioning, while maintaining low power requirements. It features a maximum supply voltage of 24 V, a maximum input resistance of 2 GOhms, a 25 nA input bias current, and a 0.5 mA operating supply current. The amplifier has a Common Mode Rejection Ratio (CMRR) of 90 dB for excellent noise immunity, as well as a Unit-Weight of 0.004938 oz. This low-power amplifier is perfect for a wide range of applications, such as charge measurement, bio-sensing, optical strain measurement, bridge-sensor amplification, and motion control current sensors. Its user-selectable gain and bandwidth can further tailor device performance for a variety of low-noise applications. In addition, the AD8223ARMZ-R7 is RoHS-compliant and is supplied in a Reel package.

Request for a quote

EMSYST

Slovakia

Extremely high load sensor with good metrological properties. Range: from 500 kN up to 3 MN Force dir: Tension / Compression

Request for a quote

EMSYST

Slovakia

Precise force sensor, not sensitive to lateral forces, well suited for testing. Range: from 1 kN up to 500 kN Force dir: Tension / Compression

Request for a quote

EMSYST

Slovakia

In-Line robust load cell with very good metrological characteristics suitable for measurements in demanding conditions like tanks weighting. Range: from 500 N up to 200 kN Force dir: Tension / Compression Version EMS151 has built-in signal conditioner with voltage or current output.

Request for a quoteResults for

Strain sensors - Import exportNumber of results

35 ProductsCountries

Company type

Category

- Sensors (25)

- Measurement and control instruments (3)

- Cooker hoods and extractor fans (1)

- Electrical & Electronic Components (1)

- Electricity - import-export (1)

- Electronics - import-export (1)

- Measurement - Equipment & Instruments (1)

- Optical measuring equipment (1)

- Steel & Metals (1)

- Weight and mass - measurement and regulation instruments (1)