- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- straightening roller

Results for

Straightening roller - Import export

GSW SCHWABE AG

Germany

Selfcentering of coils through continuously adjustable coil side guides Wideopening alligator type straightening head for easy threading From 5 to 13 individually adjustable straightening rollers to serve almost any demand on the quality of the straightening result Clockspring guard Drive via threephase servo motor; torque transmission simultaneously to all bottom straightening rollers, pinch rollers and cradle rollers

Request for a quote

GSW SCHWABE AG

Germany

No coil expansion needed Selfcentering of coils through continuously adjustable coil side guides Wideopening alligator type straightening head for easy threading From 5 to 21 individually adjustable straightening rollers to serve any almost demand on the quality of the straightening result Drive via threephase servo motor; torque transmission simultaneously to all bottom straightening rollers, pinch rollers and cradle rollers Clockspring guard Allroll drive for straightening rollers Hydraulic hold down arm (optional w powered endwheel) Hydraulic threading system with snubber and peeler (optional w powered snubber wheel) Motorized coil guides Motorized straightening rollers Hydraulic opening / closing of straightening head Hard chromed rollers Edge guides adjustable to center via handwheel (optional motorized) Jobmemory feature for all motorized functions... etc

Request for a quote

WIB SA

Switzerland

The manufacturing precision of the roller has a major influence on the quality of the final product (wires) as well as on the service life of the rollers. It is therefore essential that the ground “V” groove on the outer ring is machined and positioned precisely relative to the internal geometry. WIB only produces straightener roller bearings produced in this fashion, while many other producers machine the outer wire guide groove after assembly

Request for a quote

MAHLO GMBH & CO. KG

Germany

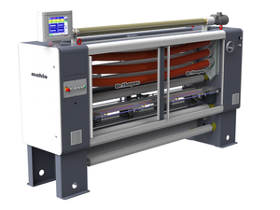

Weft straightening the way it should be ... The Orthopac RVMC is the universally employable straightening system from Mahlo for the correction of web distortions for nearly all applications. Available with hydraulic or electrical straightening roller adjustment. The modular construction allows the system to be configured to meet the demands of changing conditions and requirements.

Request for a quote

GSW SCHWABE AG

Germany

for wire ø 0,4 15 mm according to the required straightening quality, available with 5 to 13 rollers straightening rollers with precisionguiding also available as a set with 2 straightening units and angular fixations for horizontal and vertical straightening on request special perforations of the straightening rollers for noncircular material crosssection

Request for a quote

MAHLO GMBH & CO. KG

Germany

Removing all types of distortions The fusion of pin wheel and roller straightening technology perfectly combines the advantages of both technologies and provides amazing straightening results. It provides reliable, quick distortion correction also for asymmetric web distortion. An infinitely variable unclipping roller minimises residual bow and edge distortions. The intelligent drive station with special voltage control for smallest product distortion activates or deactivates automatically (e.g. in case of blockages). A bypass function is available at the push of a button for products that cannot be straightened with the pin wheel.

Request for a quote

MAHLO GMBH & CO. KG

Germany

When the going gets rough ... The Orthopac CRVMC is especially designed for high mechanical load. Thanks to reinforced components, it is ideal for processing very heavyweight and wide materials. The arc of contact of the straightening rollers thereby depends on the desired straightening effect. With products without skews and bows, the straightening rollers are not enveloped unnecessarily. When the straightening rollers engage with the product, the uniform contact of the straightening rollers with the product is ensured over the entire width. This becomes possible through our innovative and unique roller positioning drive.

Request for a quote

MAHLO GMBH & CO. KG

Germany

Fine-tune straightening of residual distortion This model represents a compact fine-straightening system for the correction of residual distortions. The special strength of the Orthopac MFRC is the extremely high straightening accuracy at relatively small distortions. The compact straightening unit is equipped with a skew and bow roller as standard. This arrangement allows for very fine adjustment of the straightening effect while permitting small device dimensions. Available with hydraulic or electrical straightening roller adjustment.

Request for a quote

GSW SCHWABE AG

Germany

To serve coil stock thicknesses of up to 15 mm Large diameter entry pinch rollers for smooth and lowwear strip transport Synchronized drive of all bottom work rollers and both entry pinch rollers Rollers are kept perfectly parallel with their penetration shown on scales or dial gauges Hardened 63 rockwell rollers with finepolished surface guarantee longevity Enormous potential for performance and straightening quality through absolutely warpresistant head construction; supported by optional backup rollers and allroll drive system Warpresistant body in modular design to allow extension with catenary rollers, threading system or loop bridge, etc. Hard chromed rollers Polyurethane coated rollers Hydraulic head opening as "cleaning stroke" Hydraulic threading systems in different grades Dial gauges for roller adjustment display Motorized adjustment of straightening rolls Jobmemory for mot. straightening roller adjustment Central edge guide adjustment via handwheel All roll drive

Request for a quote

GSW SCHWABE AG

Germany

Most simple threading Short setup as roller adjustment can be maintained with coilchanges Most comfortable maintenance and cleaning Synchronized drive of all bottom work rollers and both pinch rollers Rollers are kept perfectly parallel with adjustments shown on scales or dial gauges Hardened 63 rockwell rollers with finepolished surface guarantee longevity Warpresistant body in modular design to allow extension with catenary rollers, threading system or loop bridge, etc. Hard chromed rollers Polyurethane coated rollers Hydraulic head opening Hydraulic threading systems in different grades Dial gauges for roller adjustment display Motorized adjustment of straightening rolls Jobmemory for mot. straightening roller adjustment Central edge guide adjustment via handwheel All roll drive Movable base Manual or hydraulic loop bridge... etc.

Request for a quote

SCHNELL SPA

Italy

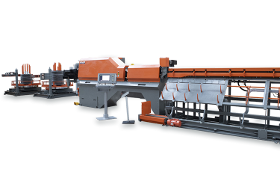

Automatic wire straightening machine, with rollers, for the production of cuttosize wires up to Ø 20 mm (#6). Driven by digital electric servomotors. Capacity 2 Ø 16 mm (#5) Max pulling speed 200 m/min (660 ft/min) Straighteners (horizontalsverticals) with electronic adjustment and independent position for the 2 wires Motorized wire change unit (Optional) Prestraightening Feeding Unit (Optional) Web Teleassistance

Request for a quote

SCHNELL SPA

Italy

Fast automatic wire straightening and cutting machine, with rollers, for the production of cuttosize wires up to Ø 16 mm (#5). Driven by digital electric servomotors. Max pulling speed 240 m/min (790 ft/min) Straighteners (horizontalvertical) with electronic setting Rollers for the extraction of the last part of the coil (Optional) Automatic 6inlets motorized wire change and insertion unit (Optional) Patented motorized horizontal wire change unit which allows to change the diameter and the coil in "Zero time" (Optional) Web Teleassistance

Request for a quote

SCHNELL SPA

Italy

Fast automatic wire straightening and cutting machine, with rollers, for the production of cuttosize wires up to Ø 13 mm (#4). Driven by digital electric servomotors. Max pulling speed 240 m/min (790 ft/min) Straighteners (horizontalvertical) with electronic setting Rollers for the extraction of the last part of the coil (Optional) Automatic 5inlets motorized wire change and insertion unit (Optional) Patented motorized horizontal wire change unit which allows to change the diameter and the coil in "Zero time" (Optional) Web Teleassistance

Request for a quote

SCHNELL SPA

Italy

Automatic wire straightening and cutting machine, with rollers, for the production of cuttosize wires up to Ø 13 mm (#4). Driven by digital electric servomotors. Capacity 2 Ø 10 mm (#3) Max pulling speed 150 m/min (495 ft/min) Straighteners with independent position and adjustment displays for the wires Cutting with Brushless Motorized wire change unit Web Teleassistance

Request for a quote

SCHNELL SPA

Italy

Fast automatic wire straightening machine, with rollers, for the production of cuttosize wires up to Ø 13 mm (#4), equipped with Senso Technology.

Request for a quote

SCHNELL SPA

Italy

Integrated plant to cut and stock precut bars made of fast automatic straighteners with rollers (such as RETA) and coil processing up to Ø 20 mm. Pulling speed up to 300 m/min. The plant is fully customizable and modular thanks to a wide range of available accessories. Fast Coil change patented system of automatic horizontal wire change (Optional); Straighteners (horizontalvertical) with electronic and independent setting for double wire feeding; Cutting with Brushless motors with adjustable wire guide, fixed and mobile cutting blades; Rollers for the extraction of the last part of the coil; Teleassistance.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

BOSPORAS

Turkey

Our 11-roller servo feeders work between 300 and 1.600 millimeters of width and, 1 and 8 millimeters of thickness. Our straightener servo machines’ full-auto piloting system works with feeder and straightener rollers. Our company mass produces 11-roller Model with static body and in accordance with Conformité Européenne (CE) Regulations.

Request for a quote

BOSPORAS

Turkey

Our 7-roller straightener servo feeders work between 300 and 1.600 millimeters of width and, 0,5 and 5 millimeters of thickness. Our straightener servo machines’ full-auto piloting system works with feeder and straightener rollers. Our company mass produces 7-roller Model with static body and in accordance with Conformité Européenne (CE) Regulations.

Request for a quote

BOSPORAS

Turkey

Our AZP 11-roller straightener servo feeders work between 300 and 1600 mm of width and 1 and 6 mm of thickness. Our 11-roller bouncer straightener servo line consists bouncing system that works in harmony with the straightener rollers. It is designed using a different technique in order to make the piloting work on multi-phased progressive dies and for the coil to fed properly. Servo feeder and straightener models allows automated feeding to the AZP high performance presses. Servo engine stimulation gear ties the gapless designed gearbox and straightener rollers together. It allows the angle between the die and the coil is 90° parallel. It has the feature of 50 mm of movement capability to the left or right from the feeder’s center. It feeds the coil materials in autonomous cycle, programmed speeds and high delicacy. Coil material feeding speed is 32 m / min.

Request for a quote

BOSPORAS

Turkey

Our company BOSPORAS, mass produces AMD models with static body and in accordance with CE regulations. Our understanding of making the “quality” our top priority has made us the top choice among customers. AMD series mini straightener servo feeders are manufactured to have 0.3 and 3 mm of coil thickness and, 100 and 200 mm of coil width. AMD Model has a total of 7 4140-material rollers that consists HRC 58 and 60 surface hardness with 5 of them being a 60-millimeter straightener roller and 2 of them being an 84-millimeter pinch roller. AMD models don’t need any external guidance because they minimize the distance between Press body and the die. Our AMD model feeders are designed to control the press system easily with its 7” ergonomic LCD color display. Besides allowing Servo Feeder Straightener to work synchronized with the Press system, control panel can also work on systems like greasing the dies via PLC external output features, multi press control and piston die.

Request for a quote

BOSPORAS

Turkey

Our 7-roller ACS Series compact system press feeding machines consist of 60 and 1300 coil width, 0,5 and 4 mm of sheet metal thickness, between 6.000 and 10.000 kilograms of coil weight capacity feeder, straightener and decoiler. 7-Roller Compact Coil Feeder System Components Hydraulic Decoiler Hydraulic Inner Tightening and Unloading Upper Arm Coil Servo Feeder Straightener Straightener Adjustment and Fine Positioning Feature Roller Group and Gear Transmission Feature Distance Detection and Proximity Sensor Feature Die Memory System Multiple External Output Options Press Automation Control Feature Operation with Touchscreen and Remote Connection Support Features

Request for a quote

BOSPORAS

Turkey

Our 11-roller ACS Series compact system press feeding machines consist of 600 and 1600 coil width, 2 and 10 mm of sheet metal thickness, between 6.000 and 15.000 kilograms of coil weight capacity feeder, straightener and decoiler. 11-Roller Compact Coil Feeder System Components Hydraulic Decoiler Hydraulic Inner Tightening and Unloading Upper Arm Coil Servo Feeder Straightener Straightener Adjustment and Fine Positioning Feature Roller Group and Gear Transmission Feature Distance Detection and Proximity Sensor Feature Die Memory System Multiple External Output Options Press Automation Control Feature Operation with Touchscreen and Remote Connection Support Features

Request for a quote

BOSPORAS

Turkey

Our 7-roller ACS Series compact system press feeding machines consist of 60 and 1300 coil width, 0,5 and 4 mm of sheet metal thickness, between 6.000 and 10.000 kilograms of coil weight capacity feeder, straightener and decoiler. 7-Roller Compact Coil Feeder System Components Hydraulic Decoiler Hydraulic Inner Tightening and Unloading Upper Arm Coil Servo Feeder Straightener Straightener Adjustment and Fine Positioning Feature Roller Group and Gear Transmission Feature Distance Detection and Proximity Sensor Feature Die Memory System Multiple External Output Options Press Automation Control Feature Operation with Touchscreen and Remote Connection Support Features

Request for a quote

TFON MACHINE

Turkey

ProcessLeveling And Residual Stress Relieve Material Thickness (mm)0,3-5 Maximum Material Width (mm)200 Minimum Material Length(mm)70 Quick Change System for Straightening Rollers- Flattening Gap AdjustmentElectromechanics/PC Control Overload Protection- ScreenTouch CE-CertificateStandard Machine Size (mm)1585x1585x1820 Total Weight (kg)2000

Request for a quoteResults for

Straightening roller - Import exportNumber of results

26 ProductsCountries

Company type