- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- steels and metals -welding

Results for

Steels and metals -welding - Import export

MARXAM PROJECT

Poland

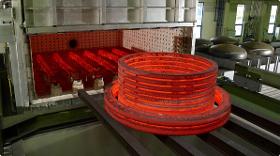

Our spot welders allow the use of alternative methods of joining metal elements. Resistance spot welding is one of the most popular techniques for joining thin-walled metals. The use of condenser welding machines allows for quick and easy mounting of fasteners (pins, screws, pins) on the surface of metals. Induction welding allows you to significantly reduce energy consumption, and thus reduces the cost of manufacturing details. This process significantly reduces the area of thermal action, which contributes to easier cleaning of the joined areas. Induction welding technology allows for its automation, which makes the process repeatable and simpler (and therefore cheaper). Thanks to the use of alternative methods of joining materials, we are able to offer our services in the construction industry; transport of liquids and gasses; automotive industry and machine manufacturing.

Request for a quote

METAL IN LTD

Bulgaria

We offer MIG-MAG and WIG welding with maximum power of electricity 400 A. Our welding machines are KEMPPI and MILLER. We make welding of steel details, tube constructions with length till 6 meters and weight till 3 tones. We also offer spot welding and robotic welding (Fanuc) at details with length till 3 meters and width till 1.5 meters, by one or by two sides. We weld ferrous metals, stainless steel and aluminum. After welding we make cleaning of welding and painting (powder and wet).

Request for a quote

AICS BUSINESS SOLUTIONS CELIK SANAYI VE TIC. LTD. STI.

Turkey

Welded construction parts are manufactured all according to ISO Standards of certifed Suppliers.

Request for a quote

AICS BUSINESS SOLUTIONS CELIK SANAYI VE TIC. LTD. STI.

Turkey

Our Heat Treating Suppliers are certified by Aeronautical and Automotive Industries. Annealing Normalizing Stress Relieving Quenching and Tempering Vacuum Hardening Homogenization Decarburization Nitriding Carburization Case Hardening and more

Request for a quote

AICS BUSINESS SOLUTIONS CELIK SANAYI VE TIC. LTD. STI.

Turkey

With our extensive supplier portal, we can cover all your needs in the field of cold and hot forged castings. Trust us in choosing the right supplier for your needs

Request for a quote

ROTA MACHINERY MANUFACTURING CONTRACTING

Turkey

"Argon-arc welding Electric arc welding Gas metal arc welding Arc welding"

Request for a quote

OREMUS S.R.O.

Czech Rep.

In our team, certified welders with more than 20 years of experience are working, using precision working plates for weldments up to 4000x6000mm and even more. Our welding shop is equipped with cranes 3,5t / 5t / 20t

Request for a quote

OREMUS S.R.O.

Czech Rep.

Straightening press CDN400 with 3100x3000mm table and 1000mm stroke helps us finish our work with great precision.

Request for a quote

OREMUS S.R.O.

Czech Rep.

It is not so common, but it greatly increases the efficiency in our welding shop

Request for a quote

QUELLTECH GMBH

Germany

Particular challenges To correct the effect of the tolerances of the parts, the welding robots path in conventional applications is usually adjusted, by means of a time consuming manual correction (teaching). The warping effect caused by the thermal expansion however cannot be compensated this way. For this purpose, QuellTech offers a perfectly tailored seam tracking solution, which is based on a QuellTech 2D-Laserline Sensor of the Q4 family. The method consists in measurement of the real position and width immediately ahead of the welding process. The laser sensor captures the real dimension of the weld bead, and the software used for this process simultaneously sends the nominal position to the robot. The robot performs a correction movement in X or Z position according to this measurement. This way not only the deviation caused by tolerances, but also the warping effect can be compensated – and the weldment takes place exactly at the required position.

Request for a quote

QUELLTECH GMBH

Germany

QuellTech Solution For this purpose, QuellTech offers a perfectly tailored seam tracking solution, which is based on a QuellTech 2D-Laserline Sensor of the Q4 family. The method consists in measurement of the real position and width immediately ahead of the welding process. The laser sensor captures the real dimension of the weld bead, and the software used for this process simultaneously sends the nominal position to the robot. The robot performs a correction movement in X or Z position according to this measurement. This way not only the deviation caused by tolerances, but also the warping effect can be compensated – and the weldment takes place exactly at the required position. The QuellTech 2D-Laserline Sensor is specially prepared to the highly disturbing ambient light from the weld process. It can be cooled and protected from weld spatter, so this model proves to be particularly adequate for operation in the harsh environment of the welding process.

Request for a quote

DOGRAR METAL

Turkey

We do not only manufacture simple sheet metal parts, we also support our clients in as many aspects as possible such as finished or semi-finished goods upon the request of our clients. Completing fasteners and fittings, powder coating, anodization, laser marking and silk screen can be given as an example of previous application for our customers.

Request for a quote

DOGRAR METAL

Turkey

Fanuc Arc welding robot with 2 meters reaching capacity can weld 5 mm -20 mm parts with multi dimensional and efficient methods. Thin design makes the robot ideal for usage in different sectors from automotive to furniture industry. Unlike traditional welding methods, you can achieve the quality from first to last part. In addition to TIG welding, We are also working with other welding methods such as stainless steel welding (MIG/MAG) and spot welding depending on our client's needs and material preferences.

Request for a quote

DOGRAR METAL

Turkey

Our machine selection may bend 240 and 300 IPE and NPI. and pipes from 21 to 76. Moreover, we can process from 15x15 rolling mills to 60x60 rolling mills also, from 20^5 sheet bar to 80x20 sheet bar.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

DOGRAR METAL

Turkey

Our machines with 2500x6000 mm and 2500x12000 mm capacities can cut 2-30 mm galvanized steel and ST 37 and 2-15 mm stainless steel. Also, they may process as inclined method for the sheets thicker than 10 mm. With our plasma cutting machines that can cut up to 12 meters in length, high thickness materials can be processed with high precision. With this production method, which has high durability and low energy consumption, production can be made at low cost. With the oxygen cutting method, we can shape materials up to 200.00 mm in thickness with additional fprhnologies such as micro-joint at a speed of 15 mitpr per minute.

Request for a quote

DOGRAR METAL

Turkey

Our machines with 1500x3000 mm and 2000*4000 mm capacities can process 0.5 - 20 mm stainless steel, S235 JR and aluminium and 0,5 - 8 mm copper, brass and titanium at high speed. No matter whether manufacturing low quantities or mass production, we are guaranteeing ISO 9001:2015 quality level and the best raw material optimization, thanks to powerfull TRUMPF machinery since 2004. The determining factor in quality and efficiency is the machine as a complete system of laser power and functions. That's exactly why you can’t produce a good part without good technology, and we always adopt the principle of production with the best technology. At the same time, with the automatic loading units we have, we can place the raw material in the machine without damaging the surface quality, and we can save a lot of time in this process compared to the traditional loading method.

Request for a quote

ZS INDUSTRIES CO., LTD

China

Material: Carbon steel: S235JR, S355JR Stainless steel: SS304, SS316 Aluminum alloy Process: Flame/plasma/laser cutting Punching/bending CO2 welding Machining Application: Agricultural & farm machinery Off-shore industry Construction equipment General machinery

Request for a quote

ZS INDUSTRIES CO., LTD

China

Part size 400*400*500mm laser cutting, flame cutting the sheets and then welding,finally wet painting

Request for a quote

AAAGILER GMBH

Germany

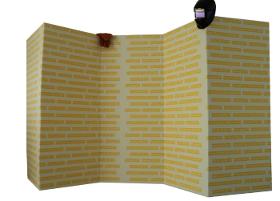

Discover our highly effective mobile welding protection wall made of cardboard - the perfect solution to protect your working environment from flying sparks and fire hazards during welding and grinding. This cut-to-size cardboard combines welding protection with environmental protection.

Request for a quote

ANDREAS BERG STAHL- UND MASCHINENBAU E.K.

Germany

Your expert in welding technics like MIG, MAG, WIG, resistance spot & stud welding, e-welding, welding robots For the returning serial welding tasks, 2 gantry welding robot system are available. With a machining length of up to 8 meters (26,2 ft), we can lealize complex customer requests thanks to 10 treatment axis performance. We are authorized to weld structural steelwork in accordance to EN1090

Request for a quote

NOVELTY STEEL

Turkey

Carbon Steel and Stainless Steel Robot Laser Welding Part Manufacturing

Request for a quote

NOVELTY STEEL

Turkey

Novelty Steel Designs and manufactures various steel frames for various structures and machinery. We produce bespoke steel frames based on the client drawings and preferences. Our modern steelwork fabrication shops have computer-aided design and detailing (CAD), which is linked directly to factory floor computer numerically controlled (CNC) machinery, creating a genuine seamless CAD/CAM environment. The accuracy of the computer-generated details being transmitted directly to the CNC machinery increases the quality standards of the production. Novelty Steel has adapted EN 1090-2 standards into its manufacturing processes supervised by experienced quality management team.

Request for a quote

NOVELTY STEEL

Turkey

Novelty Steel is an experienced fabricator of structural steel fabrications for plant constructions such as Bulk Handling Equipment, HRSG plants, Steel and Wood Industries. Some examples of the fabrications are: Steel Silos and tanks Inlet Ducts and Silencers Stair Towers Bunkers and Hoppers Pipe Supports Exhaust Stacks Our modern steelwork fabrication shops have computer-aided design and detailing (CAD), which is linked directly to factory floor computer numerically controlled (CNC) machinery, creating a genuine seamless CAD/CAM environment. The accuracy of the computer-generated details being transmitted directly to the CNC machinery increases the quality standards of the production. Novelty Steel has adapted EN 1090-2 standards into its manufacturing processes supervised by experienced quality management team.

Request for a quote

NOVELTY STEEL

Turkey

Novelty Steel Designs and manufactures various steel frames for various structures and machinery. We produce bespoke steel frames based on the client drawings and preferences. Our modern steelwork fabrication shops have computer-aided design and detailing (CAD), which is linked directly to factory floor computer numerically controlled (CNC) machinery, creating a genuine seamless CAD/CAM environment. The accuracy of the computer-generated details being transmitted directly to the CNC machinery increases the quality standards of the production. Novelty Steel has adapted EN 1090-2 standards into its manufacturing processes supervised by experienced quality management team.

Request for a quote

NOVELTY STEEL

Turkey

Novelty Steel is an experienced fabricator of structural steel fabrications for plant constructions such as Bulk Handling Equipment, HRSG plants, Steel and Wood Industries. Some examples of the fabrications are: Steel Silos and tanks Inlet Ducts and Silencers Stair Towers Bunkers and Hoppers Pipe Supports Exhaust Stacks Our modern steelwork fabrication shops have computer-aided design and detailing (CAD), which is linked directly to factory floor computer numerically controlled (CNC) machinery, creating a genuine seamless CAD/CAM environment. The accuracy of the computer-generated details being transmitted directly to the CNC machinery increases the quality standards of the production. Novelty Steel has adapted EN 1090-2 standards into its manufacturing processes supervised by experienced quality management team.

Request for a quoteResults for

Steels and metals -welding - Import exportNumber of results

192 ProductsCountries

Company type

Category

- Welding work - steels and metal (113)

- Steels and metals - welding and brazing (82)

- Autogenous welding machines (6)

- Welding, soldering and brazing - equipment and supplies (5)

- Steel & Metals (4)

- Sheet metals - stamping (3)

- Bending - steels and metals (2)

- Metal structural work (2)

- Milling - steels and metals (2)

- Stainless steels (2)

- Forming - steels and metals (1)

- Furniture - restaurants, bars and cafés (1)

- Grinding - steels and metals (1)

- Industrial piping (1)

- Offshore construction (1)

- Recycling - machines and installations (1)

- Steel (1)

- Turning - steels and metals (1)