- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- steel most

Results for

Steel most - Import export

APICURE PARIS IMPORT-EXPORT

France

Original double-walled insulated mug with a capacity of 330 ml. Made from recycled stainless steel, with a bamboo lid and matching comfortable handle. With distinctive recycled stainless steel. Presented in an individual kraft designer box and recycled bag. Steel is one of the most in-demand materials and can be found almost everywhere, from everyday products to large constructions. With countless properties, including durability and its high degree of reuse, making it a highly valued alternative in sustainability solutions. Properly processed, it allows you to obtain new resources of infinite use.

Request for a quote

XIAMEN NINESUN IMP. & EXP. CO., LTD

China

Stainless Steel Foil is the most widely used decorative materials

Request for a quote

PERGEL METAL

Turkey

Steel Construction, especially used in the construction industry, is one of the most trending materials. Steel construction houses have become very popular in recent years. It is more preferable compared to classical construction structures. It is at the forefront with its durability and fast construction. In particular, it can be said that there will be more developments in this regard in the coming years. Steel Construction will be able to see in more areas. In this regard, you can get a quality service from our company.

Request for a quote

MAROVT D.O.O.

Slovenia

Only high-quality steel is appropriate for high-quality products which are mostly assembled in the cars of our customers. By using hot forging process, we shape different types of carbon steel, all types of alloy steel and most of the time stainless steel.The Hot forging process and thus the transformation of steels has a number of specific points in its process. We have directed the development of forging into forging stainless steels, as these steels are increasingly present in automotive engines as well as in other segments of the use of forged parts. The advantage of stainless steels is that they are corrosion-resistant, and do not require additional surface protection. Through the hot forging process, we are able to transform both ferritic, martensitic and austenitic stainless steels.

Request for a quote

MAROVT D.O.O.

Slovenia

Precision forged parts are forged parts where very narrow tolerance can be achieved by following the forging process permanently. Our processes enable forging with the +/- 0.1mm tolerance. We are specialized in the production of precision forged parts weighing between 0.001kg and 1kg made of different material. The advantage of precision forged parts is that they can be used mostly in different compounds and without additional mechanical machining. Hot die drop forging is the method in our company – sticks are heated and inserted into the appropriate forging tool.After the forging process, we trim and pierce the semi-finished products to meet many shapes and other requirements. We shape stainless, alloy and carbon steels. In most cases, more complex and larger forgings are further machined.Due to the specificity of precision forgings, we provide the minimum necessary additional machining and thus reduce the machining times.

Request for a quote

FRIEDR. FREEK GMBH

Germany

The HSHP – Drum Heater (220 °C) is suitable for steel drums (and with restrictions also for plastic drums). The outer material is a Teflon which is released for contact with food. The material possesses high levels of chemical and acid resistance. However, products such as waxes, soaps and materials with high water content can be heated excellently as well. The drum heating jacket is lightweight, robust and free of silicone. The excellent thermal transfer properties due to the perfect fit result in homogenous temperatures. Our silicone-free high-temperature drum heater is available in the standard size of 200 liters but can also be made to customer specification.

Request for a quote

NOVELTY STEEL

Turkey

Sheet metal fabrication is the process of bending, cutting, punching, assembling sheet metal to form into the desired form. Special tools, such as band saws and chops saws, can also be used in the sheet metal fabrication process. These ensure even cutting throughout the process. Parts are fabricated from a single piece of sheet metal so designs should have a uniform thickness. Although carbon steel is the most prominent material for metal fabrication, stainless steel would be necessary for high corrosive environments whereas aluminium is primarily considered when weight of the product is a major limitation.

Request for a quote

NOVELTY STEEL

Turkey

Sheet metal fabrication is the process of bending, cutting, punching, assembling sheet metal to form into the desired form. Special tools, such as band saws and chops saws, can also be used in the sheet metal fabrication process. These ensure even cutting throughout the process. Parts are fabricated from a single piece of sheet metal so designs should have a uniform thickness. Although carbon steel is the most prominent material for metal fabrication, stainless steel would be necessary for high corrosive environments whereas aluminium is primarily considered when weight of the product is a major limitation.

Request for a quote

NOVELTY STEEL

Turkey

Sheet metal fabrication is the process of bending, cutting, punching, assembling sheet metal to form into the desired form. Special tools, such as band saws and chops saws, can also be used in the sheet metal fabrication process. These ensure even cutting throughout the process. Parts are fabricated from a single piece of sheet metal so designs should have a uniform thickness. Although carbon steel is the most prominent material for metal fabrication, stainless steel would be necessary for high corrosive environments whereas aluminium is primarily considered when weight of the product is a major limitation.

Request for a quote

TROTEC GMBH

Germany

Our hero made of stainless steel for self-pumped waterNone of our high-quality submerged waste water pumps of the TWP series transports more water per hour. With its resistant pump housing, the submerged pump TWP 11000 ES made of stainless steel withstands even the most extreme weather conditions. The solid submerged pump guarantees an above-average and at the same time maintenance-free service life for water withdrawal from ponds, garden wells, cisterns or rain barrels as well as for pumping out and recirculating water in swimming pools and whirlpools, flooded basements, garages and building/drainage pits. This high degree of versatility makes the TWP 11000 ES an indispensable universal helper for passionate hobby gardeners, facility managers, homeowners or craftsmen.

Request for a quote

GSW SCHWABE AG

Germany

When you deal with industrial surface treatment and your expertise is the cleaning, brushing, polishing or coating of strip steel, you most likely do not want to spend any worries about the run of the material. That’s where our Winding Lines keep your worries away – because they take care of a safe run! They work with high tension and special monitoring and deflectors to do this, with the result of a clean wound beginning to end. The machine design thus calls for especially high drive power and precision expansion systems; even something so simple as the machine base is designed special to cope with the forces… To control the precision of one layer to the next, we utilize external edge controls and servo-drive the Reels for adjustment. This way we meet the typical low tolerances in this industry – after all, the coil is the product!

Request for a quote

NOVELTY STEEL

Turkey

In a belt conveyor system, pulleys play a crucial role by altering the direction of the belt in a vertical plane. They create a continuous loop for uninterrupted operation. The pulley, also referred to as a drum, and its accompanying shaft combine to create a unified structure. Their operational features are interdependent. The evolution of conveyor pulley construction has advanced from fabricated wood to cast iron and, currently, steel fabrication. Pulleys are produced in various sizes, with the standard steel pulley being the most widely employed in conveyor systems.

Request for a quote

INDUSTRIAL BRUSHWARE LIMITED T/A IBEX INDUSTRIAL BRUSHES

United Kingdom

Rotary wire brushes are used for cleaning and deburring. They are available in a variety of diameters and bore sizes. Wire materials cover most types of steel & non- sparking configurations & range from fine to very coarse.they are available in all sizes and wire specifications. Steel, Stainless Steel, Bronze, Copper or Brass.

Request for a quote

FRAMEX

Spain

Ball pen and roller pen set made of Recycled Stainless Steel. Ball pen with twist mechanism and roller with cap, both with metal clip and blue ink, with shiny finish barrel and Recycled Stainless Steel logo included. Presented in a cork case. Steel is one of the most demanded materials and can be found almost everywhere, from everyday products to major constructions. With countless properties, including durability and a high level of reusability, it is a much valued alternative for sustainable solutions. Properly treated, new resources of infinite use can be obtained. Pen and Roller. Jumbo Refill Recycled Stainless Steel

Request for a quote

TOSYALI MAKINA A.S.

Turkey

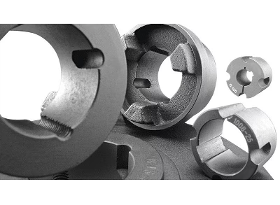

Bushings and hubs are available in many models that offer specific benefits in a variety of power transmission applications from automotive to papermaking. Our products are made of high quality steel. Most are phosphate coated or blackened to increase corrosion resistance. We offer taper, QD and keyless bushings, as well as welded and bolted hubs. Additionally, our SH bushings are resistant to heavy loads (for both torque and axial forces) and extreme temperatures. All bushings are easy to install and remove using basic tools, ensuring minimal downtime each time they are installed. A good example of this is our FX keyless bushings with 360-degree shrink fit. This allows components to be easily positioned and mounted without the need for a keyway.

Request for a quote

WESTFÄLISCHE DRAHTINDUSTRIE GMBH

Germany

With its sites in Hamm, Schwerte and Zweibrücken/Ixheim, the Westfälische Drahtindustrie bright steel division is one of the most important bright steel manufacturers in the world.The company has a recognised high level of expertise in the field of bar steel production.

Request for a quote

KAMAT GMBH & CO. KG

Germany

The KamJet is our solution for trouble-free extreme high pressure blasting on a mobile platform. The trailer mounted high pressure unit is powered by a 175kW Volvo diesel engine and produces pressures up to 3,000 bar for up to eight hours on a full tank of fuel. The KamJet mobile high-pressure unit with advanced control unit, optionally suitable for powering the Gekko system. Only high quality parts used - Our KamJet is a complete solution and comes mounted on a twin axle trailer that can travel at speeds of up to 100km/h. All parts and pipework on our units are made from stainless steel. Most importantly, it is equipped with a state of the art control system with touch screen or remote control that fully automatically controls the output pressure and speed. This makes it easy for the user to operate the machine and ensures uninterrupted operation. The KamJet can also be used with two users.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

TASK ITALY SRL

Italy

The automatic single-head cappers are designed to apply aluminum caps or screw-on and snap-on plastic caps to glass or PET bottles. All closure heads are made entirely of stainless steel, as well as most of the machine components. The speed variation is electronic, controlled by an inverter. Other capping systems are available to meet different needs: cork, crown, twist-off. It is also possible to combine 2 turrets on the same machine with different combinations, for example, screw cap + cork, cork + crown, screw cap + T-cork. The range of single-head cappers is designed for productions of up to approximately 2,500 bottles per hour and can be integrated with automatic cap feeding systems of both mechanical and pneumatic types.

Request for a quote

NINGBO FRIMA INDUSTRY CO. LTD.

China

Custom CNC Machined Shafts Check out our Custom CNC machined Shafts as below table: FRIMA(ISO 9001& IATF16949 Certified), provides precision custom machined parts in a wide range of materials to your specifications. We provide inventory management with release schedules, including in time delivery and blanket orders that are available for our clients' convenience. We are able to save our clients' money with the capability to stock our clients’ parts in our 8,000 sq. foot warehouse until they are needed. We work with a wide variety of materials, specializing in precision CNC machined parts from 1" to 6" in length and .032" to 4" inches in diameter, while holding tolerances to specification. Which is the Best Material for Custom CNC Machined Shafts ? Aluminum Brass (including using 360 brass half-hard) Beryllium Copper Bronze High Temperature Alloys Most Grades of Steel Nickel Nitronic 60 Stainless Steel Titanium Please visit at https://www.frimaparts.

Request for a quote

GFE-SOLUTIONS EUROPE SP. Z O.O.

Poland

GFE Solutions is a specialized engineering services company. Our engineers are mainly from Eastern Europe – to our customers we offer onsite- and offsite-engineering-services. All our specialists speak and write fluently English, some of them German and other languages. Our customers are mainly from machine building, automotive and steel processing industry. Most of them are from Germany and other EU-countries. Some companies have outsourced their whole engineering department to us, while others are using GFE Solutions for special project or simple engineering support. We only recruit fully experienced engineers from Eastern Europe. Many of them hold several diploma and are specialists in their qualifications. GFE Solutions also has long-established partnerships with most well-known technical universities

Request for a quote

GFE-SOLUTIONS EUROPE SP. Z O.O.

Poland

GFE Solutions is a specialized engineering services company. Our engineers are mainly from Eastern Europe – to our customers we offer onsite- and offsite-engineering-services. All our specialists speak and write fluently English, some of them German and other languages. Our customers are mainly from machine building, automotive and steel processing industry. Most of them are from Germany and other EU-countries. Some companies have outsourced their whole engineering department to us, while others are using GFE Solutions for special project or simple engineering support. We only recruit fully experienced engineers from Eastern Europe. Many of them hold several diploma and are specialists in their qualifications. GFE Solutions also has long-established partnerships with most well-known technical universities

Request for a quote

GFE-SOLUTIONS EUROPE SP. Z O.O.

Poland

GFE Solutions is a specialized engineering services company. Our engineers are mainly from Eastern Europe – to our customers we offer onsite- and offsite-engineering-services. All our specialists speak and write fluently English, some of them German and other languages. Our customers are mainly from machine building, automotive and steel processing industry. Most of them are from Germany and other EU-countries. Some companies have outsourced their whole engineering department to us, while others are using GFE Solutions for special project or simple engineering support. We only recruit fully experienced engineers from Eastern Europe. Many of them hold several diploma and are specialists in their qualifications. GFE Solutions also has long-established partnerships with most well-known technical universities

Request for a quote

VOSSE SP. Z O.O.

Poland

New in our offer! Sheet steel laser cutting! Most important paramenters of our laser machine and its possibilities Eagle eVision 1530 laser cutter with 6000W power 1. The size of the processed sheet 1500x3000 mm 2. Max. Weight of the processed material 900 kg 3. Positioning speed - X-axis 150m / min 4. Positioning speed - Y-axis 150m / min 5. Positioning speed - Z-axis 150m / min 6. Max. Cutting speed 150 m / min 7. Acceleration for X and Y axes 3 m / s2 8. Cutting accuracy (for 1 mm sheet) + -0.1 mm CNC control - Beckhoff TwinCAT CNC Positioning accuracy + - 0.05 mm Maximum thickness of the sheet metal blank Structural steel 25mm Stainless steel 25mm Aluminum 20mm Copper 12mm Brass 15mm

Request for a quote

IMETA SRL

Italy

This machine opens cans of any type, having a can height between 50mm and 270mm. It is entirely made of stainless steel. Maintenance of the most exposed parts (blades and gears) is simple – there is no need for qualified staff. Cutting and opening of the can is done in a single movement using the same lever. Magnetic fittings keep the cover in place.

Request for a quote

IMETA SRL

Italy

This machine opens cans of any type, having a can height between 50mm and 270mm (other dimensions available on request). It is entirely made of stainless steel. Maintenance of the most exposed parts (blades and gears) is simple – there is no need for qualified staff. Cutting and opening of the can is carried out in a single movement using the same lever. Magnetic fittings keep the cover in place. Electric motor 220V monophase 50Hz (380V 50Hz triphase, available on request)

Request for a quote

AMETEK SPECIALTY METAL PRODUCTS

United States

Surgical Implant 316L is a double melted stainless steel, regarded as a medical grade, this stainless steel is melted to achieve high levels of purity and cleanliness. It has excellent resistance to both general and intergranular corrosion, and pitting and crevice corrosion. The double melting allows for superior surface finish. Surgical implant 316L Stainless Steel is our most commonly sold medical stainless steel. Beyond removing impurities, this process, in combination with the unique nickel and chromium content of 316, tends to facilitate the formation of the surface chromium oxide layer that makes stainless steel corrosion resistant. There is some belief that surgical implant 316L forms a more substantial surface layer, and that this plays a strong role in protecting the host body from reactions to the nickel content of the material. Please note that we have a minimum order value of £10,000.

Request for a quote

AMETEK SPECIALTY METAL PRODUCTS

United States

Because of its strength, unique density and corrosion resistance, titanium has found applications in many industries. For high quality tubing products, it’s often a better substance to use than competing materials like stainless steels or super alloys. Titanium tubes are light weight and exceptionally corrosion and heat resistantThe density of titanium is about 60 per cent of that of steel- or nickel-based alloys giving significant weight savings in aerospace structures. The tensile strength is better than that of austenitic or ferritic stainless steels. Titanium is exceptionally corrosion resistant and exceeds the resistance of stainless steels in most environments. The metal is non-magnetic too, and has good heat transfer properties, with a melting point higher than steel alloys. Titanium is easily worked. Please note that we have a minimum order value of £10,000.

Request for a quote

SAMES KREMLIN

France

The Cyclomix™ Expert is an innovative, industrial solution that is configured to meet the needs of the customer. Description Capable of metering 1 component as well as mixing 2 and 3 component materials Flexible modular design - up to 24 programmable components PH version available for acid-catalyzed coatings Handles up to 50 recipes Constant flow technology Performance Production flush 5-step programmable sequence Weekend flush 6-step p rogrammable sequence Continuous ratio and pot life monitoring Multiple flow meter options available to meet your requirements Productivity Consistent finish quality Reduced labor - on demand mixing In-line static mixer reduces flushing solvent and faster color changes Reduced fluid waste Less rework Reduced hazardous waste Sustainability All stainless-steel construction compatible with most materials PH (acid catalyst) version available Filter/regulators assemblies are standard equipment, constructed of stainless steel compatible with most...

Request for a quote

AMETEK SPECIALTY METAL PRODUCTS

United States

Stainless steel powder 304L is a corrosion resistant material that exhibits good property stability below 1000°F. 304L powder is often the most practical stainless steel choice for parts that need the benefit of an austenitic grade. 304 Stainless steel exhibits better overall corrosion resistance than 303 grade. This material is a good choice for parts that will not be subjected to demanding machining operations. A major benefit of this material is the balance of good material performance and economical cost. The 300 Series Powders are austenitic stainless steels typically used for powdered metallurgy (P/M) press and sinter applications to make near net shape parts for a variety of industrial applications.

Request for a quoteResults for

Steel most - Import exportNumber of results

40 ProductsCountries

Company type

Category

- Computer engineering (2)

- Industrial sheet metal work (2)

- Measurement and control instruments (2)

- Steel (2)

- Steel & Metals (2)

- 3D software (1)

- Accelerometers (1)

- Advertising gadgets (1)

- Ballpoint pens (1)

- Blades and knives, industrial (1)

- Bottling and filling - machinery and equipment (1)

- Coil winders (1)

- Conveyor systems (1)

- Cutting - steels and metals (1)

- Driveshafts and micro-motors - electric (1)

- Electroheat - machines and equipment (1)

- Grinding - machine tools (1)

- Machine tools, cutting - parts and accessories (1)

- Machine tools, metal machining - parts and accessories (1)

- Mechanical transmission systems and components (1)