- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- steel and metal processing

Results for

Steel and metal processing - Import export

SCHMALE MASCHINENBAU GMBH

Germany

The X2000NC is a modular, fully servo-electric wire and tube bending machine that can be configured to customer specifications with various servo-electric units such as NC finger benders, bending slides and presses up to a force of 7000kN. Due to the variable positioning possibilities of the units, a great variety of different forming processes can be realized on the machine. This makes it possible to produce a wide variety of wire, tube and strip products on one X2000NC. Dimensions: from app. 5,50m x 2,50m, app 10 - 30 to.

Request for a quote

SCHMALE MASCHINENBAU GMBH

Germany

A clamping ring machine is a system for the automatic production of clamping rings. Schmale Maschinenbau Gmbh is one of the leading manufacturers of clamping ring machines in Europe. On our clamping ring machines, the strip material is profiled, bent and cut. Automatically closures are supplied and welded. The finished clamping ring is calibrated and stored. Via a servo-electric transfer, all processing stations are connected to each other and operated simultaneously. Thus, cycle rates of up to 28 clamping rings per minute can be realized.

Request for a quote

J.D. GECK GMBH

Germany

Our competences ,Flexible and toolbased sheet metal processing ,2D laser cutting, punched and folded parts. ,Bent wire parts madetomeasure ,Manual and automated welding. We would be happy to manufacture your preliminary products. More information available at https//www.geck.de

Request for a quote

SCHMALE MASCHINENBAU GMBH

Germany

X2000NC for producing door strikers Modular tool set on an X2000NC line for the production of door strikers from 8 mm wire. Striker sprinter tool, 3 stations, 2 m back wall, feeding of coil material via NC roller infeed, cycle output: approx. 60 pcs/min, ready-to-use, weight approx. 10 t Door striker production With these specifications, our X2000NC is the world’s fastest system for the production of door strikers for the automotive industry. With tool changes, different striker shapes can be achieved, as well as processing details such as upsetting or tapering at wire ends. Our one-of-a-kind production model enables cycle times of more than 60 pcs/minute. For this reason, we’d prefer not to share the technical details of our strategy online. If you’re interested, please arrange a meeting with a member of our field sales team. Incidentally, we also build assembly systems for coupling door strikers to striker plates.

Request for a quote

ANDREAS BERG STAHL- UND MASCHINENBAU E.K.

Germany

We process the following materials: ■ chrome-nickel steel ■ various types of steel ■ non-ferrous metals ■ various aluminium alloys steel processing, stainless steel, machine engineering, tool engineering, metal processing, sheet steel processing, material 16 Mo3, Hardox, 1.4301, 1.4571, 1.4404, S355, S235, metal products, steel products, supplier construction machinery, power station, energy station, offshore equipment, pipes, steel halls, metal construction, profiles, handrails, balconies, stairs, roofing, pallet warehouse, pallet inverters, scrap conveyors, transport racks, special frames, devices, die blocks, barrel press, fork shoes, fork extensions, industrial gates, fences, customized constructions, industrial service, furnaces, playgrounds, sports fields, cladding, casing, housing, covers, noise-protection cabins, machine frames, large milled parts, conveyor technology, conveyor line, plunge pools, tank barrels and much more

Request for a quote

TYROLIT - SCHLEIFMITTELWERKE SWAROVSKI AG & CO K.G

Austria

Thanks to many years of experience in steel and metal processing, Tyrolit is a global leader in the steel and foundry industry, particularly in tools for automatic fettling. Modern foundries use high-tech automatic grinding machines, and Tyrolit optimises these processes economically and qualitatively with an attractive range of tools. Tyrolit offers a wide range of tools, including grinding rings, grinding segments, edge-stable resin-bonded grinding wheels and diamond cutting wheels for grey and nodular cast iron. The use of diamond enables a considerable increase in performance. Application engineers provide support in finding efficient solutions, for example when combining diamond and conventional tools. . High economic efficiency . Above-average tool life . Highest surface quality . Reduced noise and dust emissions . Clean cutting quality . Maximum product safety

Request for a quote

ZS INDUSTRIES CO., LTD

China

Material: Steel: carbon steel, stainless steel, alloy steel Non-ferrous metals: Alu, brass Plastic Process: Machining/stamping/welding Surface treatment Assembly Testing Application: Agricultural & farm machinery Animal feeding device

Request for a quote

ILK IHRACAT AS.

Turkey

Sigma profiles provide an easy and versatile installation opportunity thanks to its channel structure. Sigma profiles are used in many areas such as conveyor, chassis, table, cabinet, cnc, area closure and are a special material that meets the needs of the industry. The reasons why aluminum is preferred in applications: Aluminum is lightweight. It weighs only a third of the same volume of steel. Aluminum is resistant to weather conditions, foodstuffs and many liquids and gases used in everyday life. It has an attractive appearance for both interior and exterior use and this appearance can be maintained for a long time. The strength of various aluminum alloys is equal to or higher than the strength of normal structural steel. Aluminum is an elastic material. Therefore, it is resistant to sudden impacts. In addition, its strength does not decrease at low temperatures, as is the case with steels. It is an easy metal to process. It conducts heat and electricity as well as copper.

Request for a quote

CESAL ELEKTRO S.R.O.

Czech Rep.

The maximum sheet size we can process is 2000x1250mm Maximum sheet thickness 3mm

Request for a quote

CESAL ELEKTRO S.R.O.

Czech Rep.

Allow us to briefly introduce ourselves and at the same time offer the services of our company. we precisely manufacture sheet metal parts, cabinets, covers and control cabinets made of steel, aluminum or copper sheet up to a thickness of 3 mm we treat the surface with powder paints, galvanizing we describe the screen printing method we weld or press bolts, nuts, screws onto sheet metal we have exact connector tools for 100% visual quality we make various moldings, signs (e.g. grounding) or bridges for attaching cables assembly, pre-assembly, packaging we have our own trucking company TIG, MAG and laser beam welding - we produce in small and large series

Request for a quote

FRIGORTEC GMBH

Germany

The POWDRYER™ PD08 metal powder dryer is used to dry inorganic metal powder for the complex additive manufacturing (3D printing) process. It corrects the manufacturer’s fluctuating metal powder qualities, thus optimizing the metal powder’s flowability. It also reduces the number of air inclusions in finished workpieces. Significantly higher material densities are the result. Fields of application > Particularly for metal printing products where maximum strength is required > For the printing of alloys of aluminium, titanium, tool steel, etc. > Special tools for the metal-processing industry, machine and system engineering, prototype development, and more > Aviation, aerospace, and automotive industries, plus medical and dental technology

Request for a quote

AB ANDOLŠEK ALEŠ, CNC-INŽENIRING S.P.

Slovenia

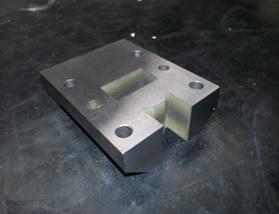

Aluminium custom made components - housing for sliding guides. Our machined parts have become an important part of: ●control lines, ●automatic assembly, ●robotic grippers, ●independent stations, ●pallet systems, ●pneumatic systems and ●production lines. Our main activity is production of individual custom components, from less demanding to very demanding and complex ones. We do our best to ensure that the services are provided with quality and in the shortest possible time. We support you by having more than 3 tons of material in stock, which guarantees us an immediate start of production. Which results in shorter delivery times and immediately providing you a new spare part.

Request for a quote

AB ANDOLŠEK ALEŠ, CNC-INŽENIRING S.P.

Slovenia

Our focus is on quality manufactured and quick delivery times while keeping a competitive pricing level. We are working with various materials like aluminium alloys, plastic, metal and steel. Our technically advanced metal processing services with 3- and 5-axis CNC milling work allow us to meet clients’ specific requirements. We do our best to ensure that the services are provided with quality and in the shortest possible time. We support you by having more than 3 tons of material in stock, which guarantees us an immediate start of production. Which results in shorter delivery times and immediately providing you a new spare part. We are being part of many development companies. We have become an important part of: ●control lines, ●automatic assembly, ●robotic grippers, ●independent stations, ●pallet systems, ●pneumatic systems ●and production lines.

Request for a quote

UNITED PROARC CORPORATION

Taiwan R.O.C.

High precision CNC cutting machine designed to be a reliable, cost effective machine in streamline appearance for high performance cutting requirements. 1.Advanced CNC controller - high performance control system 2.High accuracy - ±0.1mm 3.High bevel speed 4.Precision linear way - with copper cover for durable lifetime 5.Rigid structure, strong and precision grinding I-rail. 6.Automatic torch height control 7.Durable sealed cable chain for X & Y axes with better protection 8.Applied industries - offshore wind power, steel structure industry, metal processing industry, etc. OPTION : 1.Oxyfuel cutting torch 2.Tube cutting 3.Total cutting solution, includes: -Track foundation (H beam) -Fume extraction table -Dust collector 4.Nesting Software 5.Center drill device 6.LED lamp 7.Anti-spatter spray device *CE Conformity

Request for a quote

UNITED PROARC CORPORATION

Taiwan R.O.C.

High precision CNC cutting machine 1. Advanced CNC controller - high performance control system 2. High accuracy - ±0.1mm 3. Precision linear way with copper cover for durable lifetime 4. Rigid structure, strong and precision grinding I-rail. 5. Gas control system for Oxyfuel cutting 6. Cutting thickness max. 300mm 7. Durable sealed cable chain for X&Y axes with better protection 8. Applied industries - offshore wind power, steel structure industry, metal processing industry, etc. OPTION : 1. IHT automatic flame cutting torch 2. Plasma / oxyfuel bevel cutting 3. Tube cutting 4. Total cutting solution, includes: -Track foundation (H beam) -Fume extraction table -Dust collector 5. Nesting Software 6. Center drill device 7. LED lamp 8. Anti-spatter spray device *CE Conformity

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

PVA INDUSTRIAL VACUUM SYSTEMS GMBH

Germany

VSG systems offer a poven and economic solution for the inductive melting of metals or alloys under vacuum or protective gas atmosphere and subsequent casting. Applications: The VSG furnaces can be universally employed for melting and casting under high vacuum or different gas atmospheres in the laboratory or production, e.g. alloying, degassing, purification melting, re-melting processing of noble metals highly pure, highly alloyed steel. • Processing of: ◦noble metals ◦ processing of highly pure, highly alloyed steel ◦ High temperature resistant materials on Fe- Ni- Co- basis ◦ Solar-silicon and other special material ◦ Special- / super alloys

Request for a quote

GASTRO - HAAL, S.R.O.

Slovakia

We offer our production capacity and supply services in the field of stainless steel sheet metal processing. We can ensure the entire production process from design to delivery, based on the supplied drawing documentation (DWG, DFX, EDGE, PDF).

Request for a quote

OMKON INTERNATIONAL KFT.

Hungary

Place of OriginTURKEY Brand NameOMKON ModelOMKON - HDG Structural Steel SectorStructural Steel and Steel Structure Building Components , Metal processing: Cutting & Drawing , Metal processing: Fabrication Application FieldBUILDING, CONSTRUCTION AND STRUCTURAL STEEL,METALWORKS ,PREFABRICATED BUILDINGS ,INDUSTRIAL PLANTS MaterialSteel DescriptionStructural Steel Fabrication adhering to your Steel Structure Projects. Surface Treatment is as per your Coating Specification. Hot Dip Galvanizing applied as per applying Standard Norms. For more detailed requests please contact us along with your specific project requirement. ColorGalvanize DimensionsAdhering to Project Drawings enabling Transportation Supply Ability300 TON / MONTH Packaging & DeliveryBULK LOADING IN BUNDLES Packaging DetailsPLEASE INFORM YOUR SPECIFIC REQUIREMENTS IF ANY StandardsDIN EN ISO 9001:2015 | EN ISO 3834-2 | EN 1090-2 Exc.3 |UNE EN ISO 1461 - European Standard IncotermEX-WORKS IZMIR-TR

Request for a quote

OREMUS S.R.O.

Czech Rep.

Our work starts with precise and efficient material cutting using modern machines. Our Laser and plasma cutters are available for sheet metal processing of all grades. Laser Trumpf 4kW with interchangeable table 4000x2000mm cuts mild steel of max. 18mm with both oxygen or nitrogen. Plasma Omnicut/Hypertherm where portal is also fitted with an acetylene burner; table size 6500 x 2000mm, usually cuts max. thickness 100mm

Request for a quote

MECALTEX MECANICA GERAL DE PRECISÃO LDA

Portugal

large aluminium milling operations

Request for a quote

RPWORLD

China

CNC Machining at RPWORLD meet the diverse needs of clients ranging from single part to low- to mid-volume production. Our CNC machines run 24/7, ensuring that your high precision, complex geometries parts delivered in as fast as 3 days. We have equipped with 3-axis, 4-axis, and 5-axis machines, drilling machines, lathe machines and EDM, which are designed for creating complex shapes with high precision. The cutting-edge machines offer tight tolerances DIN ISO 2768 medium (fine), and wide machining range from 1mm to 1600mm. Industries Applied: - Medical Device Manufacturing - Automotive - Scientific Instrument - Mechanical Engineering - Robotic - Design

Request for a quoteResults for

Steel and metal processing - Import exportNumber of results

84 ProductsCountries

Category

- Steels and metals - machining (30)

- Milling - steels and metals (29)

- Turning - steels and metals (26)

- Bending - steels and metals (16)

- Cutting - steels and metals (11)

- Steel & Metals (8)

- Steel & Metal Transformation (7)

- Grinding - steels and metals (3)

- Sintering - steels and metals (3)

- Stamping - steels and metals (3)

- Folding - steels and metals (2)

- Forming - steels and metals (2)

- Galvanization - steels and metals (2)

- Perforation of steels and metals (2)

- Pipes and tubes, stainless steel (2)

- Plasma cutting machines (2)

- Abrasives, mechanical (1)

- Assemblies, hydraulic (1)

- Bending machine tools (1)

- Boring - steels and metals (1)