- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- station motor

Results for

Station motor - Import export

KUZEY GLOBAL

Turkey

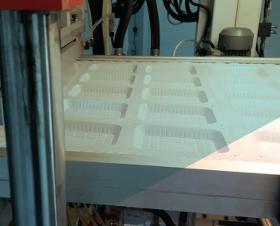

4 Column cutting station 80mm diameter resistant shafts in each column Lower and upper independent servo motor station groups Cutting right – left and forward – reverse motorized adjustment system Max 780°C cutting blade temperature and insulation plate. Fast blade damping system Cutting group stroke lower/upper 750 mm Needle bearing system Piston upper group dearance system Compression force 60 tons

Request for a quote

BALLERSTAEDT & CO. OHG

Germany

The BaCo 2400 is a fully automated, linear motor driven, filling, foil application, foil sealing and capping machine, suitable for creamy to liquid filling media. Capacity: 35-40 pcs per minute Available versions: Fill/Seal, Fill/Cap, Seal/Cap, Fill/Seal/Cap machine frame from aluminium profile indexing transport system for jars horizontally working conveyor for jar infeed and discharge position control for jars in indexing rotary transport dosing pump from 1.4404 10 l hopper with level control filling nozzles driven by LinMot-e-motor pick and place system for pre-cut foils from magazines driven by LinMot-e-motor 1 spot sealer to fix the foil at the sealing rim of the jars sealing system with conduction sealing head capping station with LinMot-e-motor infeed conveyor for caps electric cabinet with operation panel manual central lubrication system safety doors with aluminium profile frame and windows from makrolon

Request for a quote

TASK ITALY SRL

Italy

The machine allows labeling with self-adhesive labels on large cylindrical or shaped bottles and drums, from the food sector to chemicals. It enables working with products of different shapes and sizes with a few simple adjustments. These machines are always tailored to the specifications of the product to be labeled, whether round or rectangular, with one or two label distribution groups. Optional features include non-standard size conveyor belts, pulling motorizations, fixed or rotating accumulation tables, handle centering devices, thermal transfer or ink-jet printing systems. Self-adhesive stations driven by stepper motors for maximum application precision, electronic board for label start signal, precision electronic adjustment of label positioning, motorized top conveyor for stabilizing square-rectangular containers. Production: from 2,000/h to 12,000/h.

Request for a quote

TASK ITALY SRL

Italy

Machine for distributing and smoothing sparkling wine capsules and applying body label, back label, and neck label on cylindrical glass bottles from 187ml to 150cl. The monobloc's production capacity is 800 b/h with complete packaging for sparkling wine, whereas for wine bottles with label and back label, it can reach up to 1,800 b/h. Features include: automatic distributor for the sparkling wine capsule with an inclined loading platform, double optical alignment of the capsule with the brand, pre-smoothing head for inserting the capsule and smoothing using a double pneumatic head, 3 self-adhesive stations driven by stepper motors, electronic board for label start signal, electronic adjustment of label positioning via a touch-screen display, speed adjustment via inverter, full stainless steel safety protections, selection auger for 75cl cylindrical glass bottle format, pulling head, and rectangular bottle collection plate.

Request for a quote

SIEMPELKAMP MASCHINENFABRIK GMBH

Germany

Following product changes or a surface defect detected by the monitoring equipment, the aected mat section has to be rejected and discharged in time before reaching the ContiRoll®-infeed. This is ensured by Siempelkamp’s reject mat system. It is an in-line element of the forming line. Thanks to its modular design, it can be adjusted to the product parameters, enabling reliable press protection and a quick and material ecient plant restart. Features Drive/reject mat unit including track support Reject mat hopper Integration in the belt drive station Motor-adjustable table including belt deection nose Motor-adjustable belt cleaning brush Advantages Distance-controlled activation for an optimised material discharge and minimised rejects volume Options Including disintegrating rollers Including dust ap Hydraulic reject mat drive Nose stroke 3000 mm or 4000 mm

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

MASCOTT ARS LTD

Belarus

The machine is the first row. It is intended for longitudinal sawing of logs on 2-edged beams and slabs. Technical specifications Min / max. log length, mm2000-7000 Min / max. log diameter, mm140-600 (in the stone) Diameter of the saw blades, mm, 2pcs.1200 Shaft diameter, mm70 Number of turns per shaft800 Feed rate, m / min1-30 Power of electric motors with oil station, kW80.5 Input performance, m3 / per hour15-30 Length of the feed table, mm7500 Machine dimensions, mm length without a serving table2600 height 1700 width1200 Weight without a serving table 2950

Request for a quote

EDILIZIA TOOLS SRL

Romania

Welding the four 90 ° corners of the PVC profile frame and fast cleaning the welded corners. Four corner welding machine Cooling station Turning station with servo motor 2 axis CNC corner cleaning machine Automatic and manual usage possibility for CNC corner cleaning machine Production capacity 280 frames / 8 hours

Request for a quoteResults for

Station motor - Import exportNumber of results

8 ProductsCountries

Company type

Category