- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- standard rivets

Results for

Standard rivets - Import export

HONSEL-GROUP

Germany

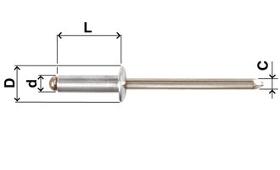

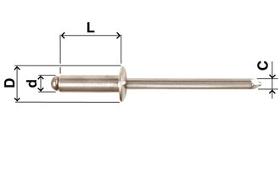

The classic model. The designation ALFO® stands for the product range of HONSEL open standard blind rivets that are available with dome, countersunk or large dome head. It covers the versions and special types described in DIN EN ISO 15977 to 15984 as well as 16582 and 16584. “Special types” by our definition are rivets with a function as described in the above standards, but with differences in certain dimensions, functional properties or material combinations.

Request for a quote

HONSEL-GROUP

Germany

HONSEL ALFO® FLEX blind rivets have been specially optimised for often problematic riveting in very soft materials or with slightly too large drill hole diameters. Due to the thinner wall thickness of the blind rivet sleeve, less force is required to deform the blind rivet sleeve. This improved deformation leads to a higher residual rivet mandrel locking. A thinner wall thickness of the blind rivet sleeve also means less influence on the hardening fluctuations caused by the annealing process. Result: The riveting function is much more consistent compared to conventional rivets. On request, the material combinations steel/steel and stainless steel/stainless steel (A2 and A4) are available as flat, countersunk or large heads. large head with a corresponding minimum quantity. Why ALFO® FLEX . Compensation for excessively large drill holes . improved residual mandrel locking . lower breaking forces . less wear on the tool . higher clamping force . ideal for soft material

Request for a quote

HONSEL-GROUP

Germany

The OPTO multigrip blind rivet with his especially embossed rivet shaft, is distinctly different to a standard blind rivet. Due to his constructive structural, the rivet guarantees lots of excellent performance characteristics: — large grip range — good filling capacity of the borehole — non-positive locking of the captive mandrel without clearance — no rattling sounds — dustproof and splash water-tight Preferred applications for OPTO multigrip blind rivets can be found in the field of vehicle manufacturing, in air conditioning technology as well as in the production of tanks and cntainers. Furthermore, this rivet type is excellently suited for use as a repair rivet. Honsel develops for this blind rivet type special variants for the serial producti on, too, e. g. large grip range low grip range with a diameter up to 8,0 mm!

Request for a quote

SFS GROUP GERMANY GMBH

Germany

A wide grip range: A single PolyGrip® blind rivet can replace to up to fi ve different dimensions of DIN standard blind rivets. • Outstanding hole fi lling capability: The rivet body expands radially during the setting process and compensates hole tolerances, centering deviations and differences in diameter, thus always building up a playfree and tight joint. • Safe rest mandrel locking: PolyGrip® blind rivets neither generate rattling noises due to free moving rest mandrels nor do they allow the risk of loss of the rest mandrel. • Splash waterproof are the PolyGrip® blind rivets under certain conditions too. Hole fi lling and rest mandrel locking make of them a real alternative to closed end rivets when it is essential to prevent water fl owing through the whole joint and not only through the rivet body. • A large closing head: for a high tensile and unbuttoning resistance.

Request for a quote

SFS GROUP GERMANY GMBH

Germany

The PolyGrip® blind rivet nuts Die PolyGrip® blind rivet nuts are the logical further development of many years of experience with our PolyGrip® multi-range blind rivets. Thanks to the benefi ts of its large drilling hole tolerance and the option of covering various grip ranges with just one fastener, the PolyGrip® blind rivet nut has become a fi rst-choice connector in many industrial applications and in trade. PolyGrip® blind rivet nuts – The GESIPA® blind rivet nuts with large grip range Bringing together multiple dimensions saves handling and storage costs while also permanently reducing the risk of confusion in the workplace and the quality problems this can result in. Large grip range: Ideally, the one PolyGrip® blind rivet nut can replace up to fi ve different dimensions of DIN standard blind rivet nuts thanks to the large grip range.

Request for a quote

HONSEL-GROUP

Germany

The OPTO multigrip blind rivets in black (RAL 9005) and white (RAL 9010) are available from stock and provide a fast, flexible solution for a variety of applications. On request, colors from all major scales are produciable. Furthermore, we offer anodized rivets or designs with large painted heads eg. for facades.

Request for a quote

HONSEL-GROUP

Germany

Pneumatic-hydraulic, with permanent and intermittent extraction The BZ 103A is the latest version of the standard tool for reliable blind rivet processing and a real classic. With reduced noise, outstanding ergonomics, individual setting of the rivet pin exhausting, an extensive scope of supply with all the necessary accessories and high-quality packaging, the BZ 103A has been proven in thousands of applications.

Request for a quote

HONSEL-GROUP

Germany

The power pack. For blind rivets up to 6.4 mm. The setting force of 20,000 N and the very large stroke of 30 mm enables not only standard blind rivets but also high-strength versions such as HONSEL FERO® Bulb and FERO® Bolt (or comparable products) and folding blind rivets up to 6.4 mm diameter to be quickly and reliably set in one step. Uncompromisingly powerful. Rivdom eBZ 2 has a modern brushless DC (BLDC) motor. Ergonomy and comfort: Quick-release mechanism: No more than one open-jaw wrench for maintenance! Individual return mode setting When using manual return mode, the trigger has to remain pressed until the rivet is sheared. When the trigger is released, the tool moves back to the front starting position. In addition Rivdom eBZ tools offer an automatic return mode. L-Boxx: Sturdy and flexible. High-quality RivdomPLUS battery system Extended 24-month manufacturer's warranty.

Request for a quote

HONSEL-GROUP

Germany

Grounding blind rivets offer a simple and reliable way of grounding a product. This is achieved by pressing the respective toothing on the conductor in the material. The grounding conductor can be used with standard cable sockets easily. The processing of grounding blind rivets can be doen with all kinds of standard type rivet tools.

Request for a quote

SFS GROUP GERMANY GMBH

Germany

Working range The rivet setting tool is designed for setting standard speed rivets from 2.4 - 4.8 mm Ø of all materials, as well as up to 4 mm Ø in stainless steel. Technical data Traction power: 3,500 N at 6 bar Stroke: 26 mm Operating pressure: 5-7 bar Air hose connection: 6 mm Ø (1/4’’) Weight: 3.0 kg Advantages • Also perfectly designed for fixed installation in production lines or semi-automatic workstations • Very practical for processing blind rivets in positions that require a vertical rivet setting process • Can be suspended on a balancer • Quick setting process, fast rates • Safe working through disposable mandrel and optional automatic switchoff • Ergonomic handling for fatigue-free work • Light and compact design • Modular construction based on the TAURUS® design • Softgrip • Tool-free conversion (spreader nosepiece and spring)

Request for a quote

SFS GROUP GERMANY GMBH

Germany

Working range The rivet setting tool is designed for setting standard speed rivets from 2.4 - 6 mm Ø of all materials. Technical data Traction power: 6,500 N at 6 bar Stroke: 30 mm Operating pressure: 5-7 bar Air hose connection: 6 mm Ø (1/4’’) Weight: 3.3 kg Advantages • Also perfectly designed for fixed installation in production lines or semi-automatic workstations • Very practical for processing blind rivets in positions that require a vertical rivet setting process • Can be suspended on a balancer • Quick setting process, fast rates • Safe working through disposable mandrel and optional automatic switchoff • Ergonomic handling for fatigue-free work • Light and compact design • Modular construction based on the TAURUS® design • Softgrip • Tool-free conversion (spreader nosepiece and spring)

Request for a quote![Angle head 90° compact [Kopie]](/filestore/vig280/opt/product/25/cb/product_96283e92.jpg)

SFS GROUP GERMANY GMBH

Germany

The angle head 90° is designed for use in very narrow and confined spaces. The rugged design makes it possible to set blind rivets with a high setting force even in working areas that are difficult to access. The angle head 90° can set standard blind rivets with a diameter up to 6.4 mm in all materials and 8 mm in aluminium with a setting force up to 20 kN. The smallest edge distance is 15 mm, the head length 110 mm. The 17/45 WK nosepiece is included in the scope of delivery as standard. Nosepieces from 17/18 to 17/40 can also be used with the angle head 90°; however, this depends on the working range of the respective tool type (AccuBird® Pro, PowerBird® Pro or PowerBird® Pro Gold Edition). Advantages • Realisation of small edge clearances • High setting force in tight installation areas • Large stroke • Simple assembly • Compact and robust design • Simple jaws maintenance • Use of standard jaws

Request for a quote

HONSEL-GROUP

Germany

According to the ARCO body-bound rivet the folding rivet forms a large upset head too. Thisguarantees an equal distribution of forces, so that especially plastics and other soft or vulnerable materials resist against cracking or pullthrough. Typically this rivet is used in all areas of industrial light weight constructions. As a result of the locked mandrel in the connection, the spread rivet is splash water resistant. VVG offers two different types – the standard split rivet and a high strength version with neoprene washer.

Request for a quote

HONSEL-GROUP

Germany

CERTO® – The Leak-tight Thanks to their cup-shaped rivet sleeves, CERTO® sealing blind rivets are the specialists when it comes to liquid-tight riveting. Thanks to this special design, the breakstem is also captive. The rivet forms a smooth, burr-free blind head and is suitable for automatic riveting. Blind rivets are one of the most extensively used fasteners worldwide. An almost endless diversity of types, sizes and formats ensure solutions for all applications. For years, HONSEL has focused primarily on the manufacture of non-standard blind rivets.

Request for a quote

SFS GROUP GERMANY GMBH

Germany

• 2.4 mm up to 6.4 mm Ø alu and copper • Up to 6 mm Ø steel & 5 mm Ø stainless steel • Up to fl ange diameter 11.4 mm • Rivet body lengths above 30 mm • Traction power up to 11,770 N (6-7 bar air pressure) • Cost effective from an annual quantity of around 500.000 blind rivets (related to the german market) • Up to 50 % time and costs savings compared to standard blind rivet devices • Rivet pistol has a large action radius • No trained personnel required for operation • Can be easily integrated into fully-automatic production systems • Up to 40 blind rivets can be processed every minute • Electronic system controls • Maintenance display & simple fault diagnosis • Customer-specifi c software modifi cation is possible • Rivet mandrels are disposed of by vacuum system • Optional Spring loaded trigger system • Interface for external memory programmable control system (SPS) can be realised via GESIPA® interface

Request for a quote

SFS GROUP GERMANY GMBH

Germany

Fields of application: • Perfectly suited for highly stressed applications in shell construction • Structural components (e.g. safety components, etc.) Strength: • "10.9" or "12.9" for blind rivet nut steel • "10.9" for blind rivet stud steel • "8.8" for blind rivet nut aluminum Customer benefits: • Fast assembly with one-sided accessibility • Solution for highly stressed applications • Process monitoring possible • Mechanical properties significantly higher than standard steel blind rivet nuts • Optimization of joints in various applications (e.g. weight reduction) • Combination with customer-specific requirements and other GESIPA® innovations

Request for a quote

FRANCE FIL INTERNATIONAL

France

This plate can be fitted to all meat rolls and roll crocs on the market. It is riveted to the standard hole drilled in all our meat rolls.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

FAR SRL SISTEMI DI FISSAGGIO

Italy

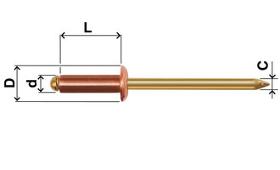

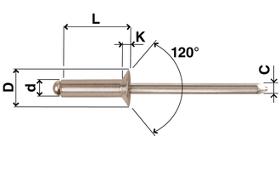

With reference to the Specifications: EN ISO 15977 dome head EN ISO 15978 countersunk head SURFACE TREATMENTS ON ALUMINIUM: Anodizing : it is possible on all rivet bodies in aluminium alloy, except for sealed rivet bodies due to the particular methodology of production. Epoxy painting.

Request for a quote

FAR SRL SISTEMI DI FISSAGGIO

Italy

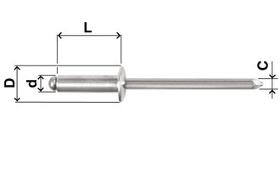

With reference to the Specification: EN ISO 16582

Request for a quote

FAR SRL SISTEMI DI FISSAGGIO

Italy

MATERIALS: Body: Steel C4C (EN 1.0303) Nail: white zinc plated steel with Chrome III. SURFACE TREATMENTS: Zinc plating: white zinc plated with Chrome III with minimum thickness of 5mm Epoxy painting.

Request for a quote

FAR SRL SISTEMI DI FISSAGGIO

Italy

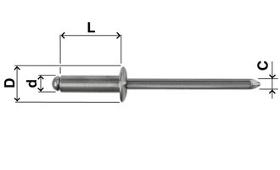

MATERIALS: Body: AlMg2,5 (EN AW 5052) Nail: AlMg5 (EN AW 5019) SURFACE TREATMENTS ON ALUMINIUM: Anodizing: it is possible on all rivet bodies in aluminium alloy, except for sealed rivet bodies due to the particular methodology of production. Epoxy painting.

Request for a quote

FAR SRL SISTEMI DI FISSAGGIO

Italy

With reference to the Specifications: EN ISO 15977 dome head EN ISO 15978 countersunk headSURFACE TREATMENTS ON ALUMINIUM: Anodizing : it is possible on all rivet bodies in aluminium alloy, except for sealed rivet bodies due to the particular methodology of production. Epoxy painting.

Request for a quote

FAR SRL SISTEMI DI FISSAGGIO

Italy

SURFACE TREATMENTS ON ALUMINIUM: Anodizing: it is possible on all rivet bodies in aluminium alloy, except for sealed rivet bodies due to the particular methodology of production. Epoxy painting.

Request for a quote

FAR SRL SISTEMI DI FISSAGGIO

Italy

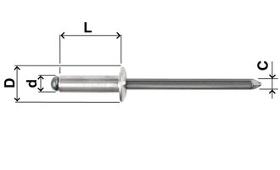

With reference to the Specification: EN ISO 15983 dome head EN ISO 15984 countersunk head 522 525 Materials: Body: Austenitic stainless steel (A2) - Aisi304Cu - X3CrNiCu18-9-4 (EN 1.4567). Nail: Austenitic stainless steel (A2) - Aisi304 - X5CrNi18-10 (EN 1.4301).

Request for a quote

FAR SRL SISTEMI DI FISSAGGIO

Italy

With reference to the Specification: EN ISO 15983 dome head EN ISO 15984 countersunk head 522 525 Materials: Body: Austenitic stainless steel (A2) - Aisi304Cu - X3CrNiCu18-9-4 (EN 1.4567). Nail: Austenitic stainless steel (A2) - Aisi304 - X5CrNi18-10 (EN 1.4301).

Request for a quote

FAR SRL SISTEMI DI FISSAGGIO

Italy

Materials: Body: Copper-Nickel alloy, with 80% of Copper and 20% of Nickel - ISO429 Nail: Austenitic stainless steel (A2) - Aisi304 - X5CrNi18-10 (EN 1.4301).

Request for a quote

FAR SRL SISTEMI DI FISSAGGIO

Italy

Body: Austenitic stainless steel (A4) - Aisi316Cu - X3CrNiCuMo 17-11-3-2 (EN 1.4578) Nail: Austenitic stainless steel (A4) - Aisi316 - X5CrNiMo17-12-2 (EN 1.4436).

Request for a quote

FAR SRL SISTEMI DI FISSAGGIO

Italy

With reference to the Specification: EN ISO 15983 dome head EN ISO 15984 countersunk head 522 525 Materials: Body: Austenitic stainless steel (A2) - Aisi304Cu - X3CrNiCu18-9-4 (EN 1.4567). Nail: Austenitic stainless steel (A2) - Aisi304 - X5CrNi18-10 (EN 1.4301).

Request for a quoteResults for

Standard rivets - Import exportNumber of results

42 ProductsCountries

Company type