- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- stainless steel tubes- seamless

Results for

Stainless steel tubes- seamless - Import export

AMETEK SPECIALTY METAL PRODUCTS

United States

Alloy 209 is a fully austenitic nitrogen strengthened stainless steel, having twice the yield strength and superior corrosion resistance at room temperature when compared to 316/316L or 317/317L stainless steels. This grade does not become magnetic when cooled to sub-zero temperatures or to a cold working process and has high resistance to sulphide stress corrosion cracking in both annealed and cold worked/ cold worked & aged form up to 30 HRc hardness. Please note that we have a minimum order value of £10,000.

Request for a quote

AMETEK SPECIALTY METAL PRODUCTS

United States

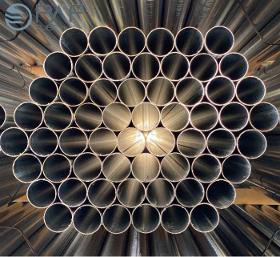

Stainless steel grades cover a wide range of compositions which result in the generation of a variety of microstructures and mechanical properties. This group of alloys is useful for the replacement of mild steel in structures and components. Stainless Steel tubes manufactured by Fine Tubes have an excellent combination of corrosion resistance, metallurgical stability and formabilityStainless steels are favoured because they are very cost effective. They also have an excellent combination of corrosion resistance, metallurgical stability, formability, and are easily welded. Their fabrication characteristics, good mechanical properties and attractive finished appearance make high quality stainless steel tubing a popular choice in a range of industries. Please note that we have a minimum order value of £10,000.

Request for a quote

STAPPERT INTRAMET SA

Belgium

Stainless steel tubes 1.4301 304L 1.4404 316L 1.4571 316TI, 321, 1.4541 Stainless steel round bars 1.4301 1.4404 1.4571 1.4541 1.4021 1.4006 1.4104 Welded and seamless stainless steel tubes 904L 1.4539 UB6 - Full stainless steel round bars UB6 904L 1.4539 Refractory tubes and round bars 309 1.4828 1.4833 310 310S 1.4841 1.4845- Duplex tubes UNS S31803 1.4462 Super duplex tubes UNS S32750 S32760 1.4410 1.4501 Duplex super duplex full round bars 1.4462 1.4410 1.4501 Stainless steel sheets 1.4301 304L 1.4404 316L 1.4571 316TI, 321, 1.4541 Refractory sheet 309 1.4828 1.4833 310 310S 1.4841 1.4845- Duplex sheets UNS S31803 1.4462 Super duplex sheets UNS S32750 S32760 1.4410 1.4501 Stainless steel sheets UB6 904L 1.4539 Alloy tubes 600; 601; 800; 825 Hastelloy C276 - Tubes and sheets 2.4816; 2.4851; 2.4856; 2.4360 Duplex super duplex stainless steel flanges 904L UB6 1.4539

Request for a quote

STAPPERT INTRAMET SA

Belgium

Stainless steel tubes 1.4301 304L 1.4404 316L 1.4571 316TI, 321, 1.4541 Stainless steel round bars 1.4301 1.4404 1.4571 1.4541 1.4021 1.4006 1.4104 Welded and seamless stainless steel tubes 904L 1.4539 UB6 - Full stainless steel round bars UB6 904L 1.4539 Refractory tubes and round bars 309 1.4828 1.4833 310 310S 1.4841 1.4845- Duplex tubes UNS S31803 1.4462 Super duplex tubes UNS S32750 S32760 1.4410 1.4501 Duplex super duplex full round bars 1.4462 1.4410 1.4501 Stainless steel sheets 1.4301 304L 1.4404 316L 1.4571 316TI, 321, 1.4541 Refractory sheet 309 1.4828 1.4833 310 310S 1.4841 1.4845- Duplex sheets UNS S31803 1.4462 Super duplex sheets UNS S32750 S32760 1.4410 1.4501 Stainless steel sheets UB6 904L 1.4539 Alloy tubes 600; 601; 800; 825 Hastelloy C276 - Tubes and sheets 2.4816; 2.4851; 2.4856; 2.4360 Duplex super duplex stainless steel flanges 904L UB6 1.4539

Request for a quote

STAPPERT INTRAMET SA

Belgium

Stainless steel tubes 1.4301 304L 1.4404 316L 1.4571 316TI, 321, 1.4541 Stainless steel round bars 1.4301 1.4404 1.4571 1.4541 1.4021 1.4006 1.4104 Welded and seamless stainless steel tubes 904L 1.4539 UB6 - Full stainless steel round bars UB6 904L 1.4539 Refractory tubes and round bars 309 1.4828 1.4833 310 310S 1.4841 1.4845- Duplex tubes UNS S31803 1.4462 Super duplex tubes UNS S32750 S32760 1.4410 1.4501 Duplex super duplex full round bars 1.4462 1.4410 1.4501 Stainless steel sheets 1.4301 304L 1.4404 316L 1.4571 316TI, 321, 1.4541 Refractory sheet 309 1.4828 1.4833 310 310S 1.4841 1.4845- Duplex sheets UNS S31803 1.4462 Super duplex sheets UNS S32750 S32760 1.4410 1.4501 Stainless steel sheets UB6 904L 1.4539 Alloy tubes 600; 601; 800; 825 Hastelloy C276 - Tubes and sheets 2.4816; 2.4851; 2.4856; 2.4360 Duplex super duplex stainless steel flanges 904L UB6 1.4539

Request for a quote

STAPPERT INTRAMET SA

Belgium

Stainless steel tubes 1.4301 304L 1.4404 316L 1.4571 316TI, 321, 1.4541 Stainless steel round bars 1.4301 1.4404 1.4571 1.4541 1.4021 1.4006 1.4104 Welded and seamless stainless steel tubes 904L 1.4539 UB6 - Full stainless steel round bars UB6 904L 1.4539 Refractory tubes and round bars 309 1.4828 1.4833 310 310S 1.4841 1.4845- Duplex tubes UNS S31803 1.4462 Super duplex tubes UNS S32750 S32760 1.4410 1.4501 Duplex super duplex full round bars 1.4462 1.4410 1.4501 Stainless steel sheets 1.4301 304L 1.4404 316L 1.4571 316TI, 321, 1.4541 Refractory sheet 309 1.4828 1.4833 310 310S 1.4841 1.4845- Duplex sheets UNS S31803 1.4462 Super duplex sheets UNS S32750 S32760 1.4410 1.4501 Stainless steel sheets UB6 904L 1.4539 Alloy tubes 600; 601; 800; 825 Hastelloy C276 - Tubes and sheets 2.4816; 2.4851; 2.4856; 2.4360 Duplex super duplex stainless steel flanges 904L UB6 1.4539

Request for a quote

STAPPERT INTRAMET SA

Belgium

Stainless steel tubes 1.4301 304L 1.4404 316L 1.4571 316TI, 321, 1.4541 Stainless steel round bars 1.4301 1.4404 1.4571 1.4541 1.4021 1.4006 1.4104 Welded and seamless stainless steel tubes 904L 1.4539 UB6 - Full stainless steel round bars UB6 904L 1.4539 Refractory tubes and round bars 309 1.4828 1.4833 310 310S 1.4841 1.4845- Duplex tubes UNS S31803 1.4462 Super duplex tubes UNS S32750 S32760 1.4410 1.4501 Duplex super duplex full round bars 1.4462 1.4410 1.4501 Stainless steel sheets 1.4301 304L 1.4404 316L 1.4571 316TI, 321, 1.4541 Refractory sheet 309 1.4828 1.4833 310 310S 1.4841 1.4845- Duplex sheets UNS S31803 1.4462 Super duplex sheets UNS S32750 S32760 1.4410 1.4501 Stainless steel sheets UB6 904L 1.4539 Alloy tubes 600; 601; 800; 825 Hastelloy C276 - Tubes and sheets 2.4816; 2.4851; 2.4856; 2.4360 Duplex super duplex stainless steel flanges 904L UB6 1.4539

Request for a quote

STAPPERT INTRAMET SA

Belgium

Stainless steel tubes 1.4301 304L 1.4404 316L 1.4571 316TI, 321, 1.4541 Stainless steel round bars 1.4301 1.4404 1.4571 1.4541 1.4021 1.4006 1.4104 Welded and seamless stainless steel tubes 904L 1.4539 UB6 - Full stainless steel round bars UB6 904L 1.4539 Refractory tubes and round bars 309 1.4828 1.4833 310 310S 1.4841 1.4845- Duplex tubes UNS S31803 1.4462 Super duplex tubes UNS S32750 S32760 1.4410 1.4501 Duplex super duplex full round bars 1.4462 1.4410 1.4501 Stainless steel sheets 1.4301 304L 1.4404 316L 1.4571 316TI, 321, 1.4541 Refractory sheet 309 1.4828 1.4833 310 310S 1.4841 1.4845- Duplex sheets UNS S31803 1.4462 Super duplex sheets UNS S32750 S32760 1.4410 1.4501 Stainless steel sheets UB6 904L 1.4539 Alloy tubes 600; 601; 800; 825 Hastelloy C276 - Tubes and sheets 2.4816; 2.4851; 2.4856; 2.4360 Duplex super duplex stainless steel flanges 904L UB6 1.4539

Request for a quote

AMETEK SPECIALTY METAL PRODUCTS

United States

21Cr-6Ni-9Mn is a high manganese nitrogen strengthened, austenitic stainless steel. It combines high strength in the annealed condition, excellent resistance to oxidation at high temperatures as well as good resistance to lead oxide and a high level of corrosion resistance at ambient temperatures. The alloy can be fabricated and formed much the same as type 304 and 316, and is readily wieldable. It remains nonmagnetic after severe cold work. Please note that we have a minimum order value of £10,000.

Request for a quote

AMETEK SPECIALTY METAL PRODUCTS

United States

Alloys 304 (S30400) and 304L (S30403) stainless steels are variations of the 18 percent chromium – 8 percent nickel austenitic alloy, the most familiar and most frequently used alloy in the stainless steel family. High strength, excellent corrosion resistance and minimized carbon content make Alloy 304 and 304L Stainless Steels useful for applications where welding is required. Uses include architectural mouldings and trim, welded components of chemical, textile, paper, pharmaceutical and chemical industry processing equipment. Other advantages are its resistance to oxidation, excellent formability, ease of fabrication and cleaning, excellent strength to weight ratio and good toughness at cryogenic temperatures. For severely corrosive environments,the lower content of Type 304L is preferred because of its greater immunity to intergranular corrosion. Please note that we have a minimum order value of £10,000.

Request for a quote

ATTEC ULUSLARARASI DIS TICARET A.S.

Turkey

Bright steel EN 10278 The surface is significantly improved due to at least one additional work step – the primary material is beeing drawn, pickled or grinded for this purpose. The bending behaviour can be significantly improved due to additional heat treatment. Facts and Figures Diameter (OD)19,0 mm – 120,0 mm MaterialS235JRC S355J2 C15, C30, C45 other materials upon request Treatment condition+C, +SH, +SL (h7) +QT, annealed TestsUS testing (extra charged) ATTEC Uluslararasi Dis Ticaret A.S. Barbaros Mah. Mor Sumbul Sk Varyap Meridian I Blok No: 1 Kat:17 D:238 Atasehir 34746 Istanbul/Turkiye Mr.Ahmet Becenoglu Export Marketing Manager Tel: +90 216 488 88 90 – 98 Fax:+90 216 488 98 38 Gsm:+90 532 787 90 89

Request for a quote

ATTEC ULUSLARARASI DIS TICARET A.S.

Turkey

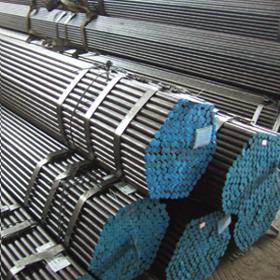

BOILER TUBES •EN 10216-2 •EN 10216-3 •EN 10217-2 •EN 10217-3 Seamless tubes for pressure purposes EN 10216-2 •unalloyed and alloyed tubes, increased temperature Seamless boiler tubes of this standard have extraordinary temperature and pressure resistance. Due to the production process, a great deal can be offered with regard to purpose-optimized steel qualities. Facts and Figures Diameter (OD)21,0 mm – 610 mm Wall thickness (WT)2,0 mm – 60,0 mm MaterialP195 GH P235 GH, P265 GH, 16Mo3 13CrMo4-5, 25CrMo4 10CrMo9-10 Treatment condition+N TestsTC1 (not including US testing) TC2 (including US testing) VersionsBlack, painted Device pressure standardsAD-2000 W0, AD 2000 W4, PED ATTEC Uluslararasi Dis Ticaret A.S. Barbaros Mah. Mor Sumbul Sk Varyap Meridian I Blok No: 1 Kat:17 D:238 Atasehir 34746 Istanbul/Turkiye Mr.Ahmet Becenoglu Export Marketing Manager Tel: +90 216 488 88 90 – 98 Fax:+90 216 488 98 38 Gsm:+90 532 787 90 89

Request for a quote

CYBERSTEEL

Russia

GENERAL TUBES & PIPES (GTP) These tubes & pipes for general application are used as elements for pipelines in a wide variety of industries BOILER TUBES Boiler tubes are used in the heat generation industry as part of tubular components for boilers in power and industrial plants. INSTRUMENTATION TUBING (IT) High precision stainless steel tubing. HEAT EXCHANGER TUBING (HEX) Heat exchanger tubes are designed to transfer heat and are mostly used in the heating, cooling, ventilation, condensation and evaporation processes. HOLLOW BARS (HB) Thick-walled seamless stainless steel tubes used for mechanical purposes.

Request for a quote

HS UMFORMTECHNIK GMBH

Germany

Our stainless steel pipes offer the following characteristics: pipe ends deburred quantity delivered in accordance with customer’s specifications well and protective transport packed

Request for a quote

HS UMFORMTECHNIK GMBH

Germany

Suction lances / suction tubes can be delivered in different diameters right from stock. We also can manufacture according to your drawing and/or sketch or sample. material: stainless steel AISI 304 or aluminium AlMgSi 0.5 F22 in all common tube dimension 40.0 / 50.0 and 60.3 mm right from stock special versions can be realised at short notice and for short delivery

Request for a quote

EC PLAZA

South Korea

Since UHP (Ultra High Purity) tubes with high corrosion resistanceas well as good internal roughness and cleanliness are needed in Semiconductor field,TRIS provides tube OD size from 1/4 inch to 2 inch for EP (Electro Polishing) process with high quality. TRIS is a supplier to Global Semiconductor manufacturers through EP companies. Since 2004, TRIS has been supplying more than 1 million meters of seamless clean BA tube every year.

Request for a quote

SHENZHEN HONGSUN PRECISION TECHNOLOGY CO., LTD

China

Do you sell or make similar products?

Sign up to europages and have your products listed

ANKARA BRONZ

Turkey

It is the quality with the best malleability feature among the austenitics. Its malleability capability is around 78% and it is named as the automat of stainless steel. Although the sulfur (S) addition improves its malleability, it also reduces corrosion resistance (lower than 304) and weakens its formability, it is especially not suitable for straight bending. Despite sulfur, its toughness degree is the same as 304.

Request for a quote

AMETEK SPECIALTY METAL PRODUCTS

United States

Fine Tubes has a long history of manufacturing high-quality tubes for nuclear fuel rods, going back to the UK’s first generation of gas cooled reactors in the 1970s. Today we support customers worldwide at the earliest stages of design engineering for new builds, plant maintenance, global life extension projects and Small Modular Reactors (SMR). Nuclear Fuel Rods and Cans Our tubes are deployed in the nuclear fuel rods and cans of advanced gas-cooled reactors. Here they endure extreme temperatures and pressures. Precision, quality, and performance are crucial. Please note that we have a minimum order value of £10,000.

Request for a quote

AMETEK SPECIALTY METAL PRODUCTS

United States

UNS NO8904, commonly known as 904L, is a low carbon high alloy austenitic stainless steel which is widely used in applications where the corrosion properties of AISI 316L and AISI 317L are not adequate. The addition of copper to this grade gives it corrosion resistant properties superior to the conventional chrome nickel stainless steels, in particular to sulphuric, phosphoric and acetic acids. However, there is limited use with hydrochloric acids. It also has a high resistance to pitting in chloride solutions, a high resistance to both crevice and stress corrosion cracking. Alloy 904L performs better than other austenitic stainless steels due to the higher alloying of nickel and molybdenum. The grade is non-magnetic in all conditions and has excellent formability and weldability. The austenitic structure also gives this grade excellent toughness, even down to cryogenic temperatures. Please note that we have a minimum order value of £10,000.

Request for a quote

AMETEK SPECIALTY METAL PRODUCTS

United States

The high precision seamless tubes manufactured at Fine Tubes begin their journey as seamless tube extrusions, in a range of different sizes. This material is reduced in size several times until it gradually reaches the exact specifications our customers require. Each time we perform a reduction process, the tube needs to be cut, cleaned and heat treated before the next one can commence. Please note that we have a minimum order value of £10,000.

Request for a quote

AMETEK SPECIALTY METAL PRODUCTS

United States

The microstructures inside duplex stainless steels are approximately 50 per cent austenite and 50 per cent ferrite, and consequently duplex products share the physical properties of both ferritic and austenitic grades. Duplex stainless steels are resistant to the cracking caused by chloride stress corrosion in austenitic grades, and have improved resistance to localised corrosion. This family of stainless steels has roughly twice the yield strength of their counterpart austenitic grades . Higher hardness values provide better wear resistance for high precision tubes. Duplex stainless steel tubes have high hardness and wear resistance propertiesDuplex steels are easily welded and formed, similar to austenitic grades. Depending on chromium, nickel and molybdenum content, duplex stainless steels are divided into four main categories: lean duplex, duplex, super duplex and hyper duplex. Please note that we have a minimum order value of £10,000.

Request for a quote

AMETEK SPECIALTY METAL PRODUCTS

United States

347 (UNS S34700/1.4550) is a fully austenitic niobium stabilised stainless steel. The addition of Niobium reduces the creation of carbide precipitation in service between 430 to 900 degrees C and during welding processes and increases the mechanical strength of the material. This grade has good resistance to oxidation and corrosion along with good creep strength and can be used at temperatures where carbide precipitation may occur in non-stabilised grades e.g., 304. It is used principally in aerospace exhaust manifolds and engine components, chemical processing equipment running at high temperatures and in nuclear processing piping. Please note that we have a minimum order value of £10,000.

Request for a quote

AMETEK SPECIALTY METAL PRODUCTS

United States

6 Mo (UNS S31254) is a super austenitic stainless steel with a high level of molybdenum and nitrogen, providing high resistance to pitting and crevice corrosion as well as high strength compared with conventional austenitic stainless steels such as 316L. The alloy can provide excellent resistance to stress corrosion cracking allowing tube cold formingand may be used without the necessity to re-anneal at testing up to 120°C. Please note that we have a minimum order value of £10,000.

Request for a quote

AMETEK SPECIALTY METAL PRODUCTS

United States

Grade 316 is the standard molybdenum-bearing grade, second inoverall volume production to 304 amongst the austenitic stainless steels. The molybdenum gives 316 better overall corrosion resistant properties than Grade 304, particularly higher resistance to pitting and crevice corrosion in chloride environments. Grade 316L, the low carbon version of 316 and has very high immunity from sensitization (grain boundary carbide precipitation). It is extensivly used in the oil and gas and chemical industries for its cost effective corrosion resistance and ease of fabrication. There is commonly no appreciable price difference between 316 and 316L stainless steel. The austenitic structure also gives these grades excellent toughness, even down to cryogenic temperatures. Compared to chromium-nickel austenitic stainless steels, 316L stainless steel offers higher creep, stress to rupture and tensile strength at elevated temperatures. Please note that we have a minimum order value of £10,000.

Request for a quote

AMETEK SPECIALTY METAL PRODUCTS

United States

S20910 stainless steel provides a combination of good corrosion resistance and strength not found in any other commercial material available in its price range. This austenitic stainless steel has corrosion resistance greater than that provided by types 316 and 316L, plus approximately twice the yield strength at room temperature in the annealed condition. In addition S20910 stainless steel has very good mechanical properties at both elevated and sub-zero temperatures a well as outstanding cryogenic properties. And, unlike many austenitic stainless steels, 22-13-5 stainless steel can be heavily cold worked to enhance its yield strength and remain non-magnetic. Please note that we have a minimum order value of £10,000.

Request for a quote

AMETEK SPECIALTY METAL PRODUCTS

United States

Grade 316 is the standard molybdenum-bearing grade, second in overall volume production to 304 amongst the austenitic stainless steels. The molybdenum gives 316 better overall corrosion resistant properties than Grade 304, particularly higher resistance to pitting and crevice corrosion in chloride environments. Grade 316L, the low carbon version of 316 and has very high immunity from sensitization (grain boundary carbide precipitation). It is extensively used in the oil and gas and chemical industries for its cost effective corrosion resistance and ease of fabrication. There is commonly no appreciable price difference between 316 and 316L stainless steel. The austenitic structure also gives these grades excellent toughness, even down to cryogenic temperatures. Compared to chromium-nickel austenitic stainless steels, 316L stainless steel offers higher creep, stress to rupture and tensile strength at elevated temperatures. Please note that we have a minimum order value of £10,000.

Request for a quote

AMETEK SPECIALTY METAL PRODUCTS

United States

Alloys 304 (S30400) and 304L (S30403) stainless steels are variations of the 18 percent chromium – 8 percent nickel austenitic alloy, the most familiar and most frequently used alloy in the stainless steel family. High strength, excellent corrosion resistance and minimized carbon content make Alloy 304 and 304L Stainless Steels useful for applications where welding is required. Uses include architectural mouldings and trim, welded components of chemical, textile, paper, pharmaceutical and chemical industry processing equipment. Other advantages are its resistance to oxidation, excellent formability, ease of fabrication and cleaning, excellent strength to weight ratio and good toughness at cryogenic temperatures. Please note that we have a minimum order value of £10,000.

Request for a quoteResults for

Stainless steel tubes- seamless - Import exportNumber of results

45 ProductsCountries

Category

- Pipes and tubes, stainless steel (38)

- Stainless steels (10)

- Pipes and tubes, steel (6)

- Seamless pipes and tubes - ferrous metal (2)

- Boilers, stainless steel (1)

- Handrails and bannisters (1)

- Industrial piping (1)

- Pipe and tube fittings - ferrous metal (1)

- Pipes and tubes - non-ferrous metal (1)

- Steel & Metals (1)