- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- spring-applied brakes

Results for

Spring-applied brakes - Import export

KENDRION (VILLINGEN) GMBH

Germany

The Elevation Line includes both DC spring-pressure single-disc brakes as well as spring-pressure double-disc brakes which comply with EN 81 (Safety Regulations Concerning the Design and Installation of Elevators). Integrated micro-switches allow for remote inquiry of the brake condition (armature position, wear, armature bearing). Owing to the patented safety concept, the otherwise mandatory testing of the dual-circuit braking system of the spring-pressure brake at the approval of the elevator system can be dropped. The brake can be used in places where short construction lengths with respective system components like motor, gear and brake must be realized. The Elevation Line is primarily used for elevators, but can be used wherever the brake must meet demanding safety requirements. Electromagnetic spring-pressure brakes build up the braking torque when the current is switched off.

Request for a quote

KENDRION (VILLINGEN) GMBH

Germany

The EEX Line includes spring-pressure single-disc brakes provided with explosion protection for explosion-hazardous areas. The spring-pressure brake with firedamp protection is suitable for underground excavations with danger of firedamp. In spring-pressure brakes with explosion protection, those parts which might ignite explosive mixtures are incorporated in a housing. If the mixture inside the housing explodes, the latter prevents a transfer of the explosion to the mixtures surrounding the housing. The brake is equipped with four thermal circuit breakers and one micro-switch. The micro-switch prevents starting against the unlifted brake. The thermal circuit breakers are series-connected with the micro-switch and interrupt the control circuit of the machine as soon as there is an inadmissibly high temperature at the brake. The brake is seawater-resistant. By means of the attached hand lifting feature, the braking effect can be manually neutralized.

Request for a quote

KENDRION (VILLINGEN) GMBH

Germany

The Compact Line includes spring-pressure single-disc brakes that can be mounted as complete units to the motor with very little assembly work. The compact design is of advantage when limited space complicates mounting. Electromagnetically-operated spring-applied brakes build up the braking torque when the current is switched off.

Request for a quote

KENDRION (VILLINGEN) GMBH

Germany

The Classic Line includes DC spring-pressure single-disc and multi-disc brakes which, due to their robust design and the variable connection technology, meet the requirements of demanding applications. Electromagnetically-operated spring-applied brakes build up the braking torque when the current is switched off and the electromagnetic force is therefore neutralized.

Request for a quote

KENDRION (VILLINGEN) GMBH

Germany

The Slim Line includes spring-pressure single-disc brakes for brake discs mounted non-positive on the shafts to be retarded. The brake disc, which is permanently connected to the shaft, can be designed as a motor fan. Owing to the single-disc brake design, SLIM LINE brakes are particularly flat. Based on the working principle, residue-free lifting is achieved. Electromagnetically-operated spring-pressure brakes build up the braking torque when the current is switched off.

Request for a quote

KENDRION (VILLINGEN) GMBH

Germany

The VARIO LINE includes DC spring-pressure single-disc brakes, which can be matched to the individual application due to a wide range of variants. Electromagnetically-operated spring-pressure brakes build up the braking torque when the current is switched off. By means of the electromagnetic force or an additionally mounted hand lifting device, the braking effect can be neutralized. Fitting dimensions and the grading of the type series of the VARIO LINE are matched to IEC motors.

Request for a quote

KENDRION (VILLINGEN) GMBH

Germany

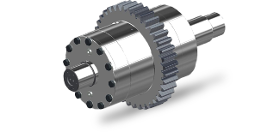

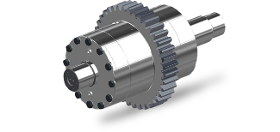

The spring-applied single-disc brakes in the Servo Line series are designed to operate dry. They can be mounted to the A-face or B-face end shield inside the servo motor. The braking action generated by the compression springs is neutralized by applying the electromagnetic principle involving generation of a magnetic field. The brakes engage in unpowered condition and release when DC voltage is applied. The brakes are equipped with a flange and firmly fastened with screws. Thanks to a specially developed and patented manufacturing method, the rated air gap tolerance can be reduced to a few hundredths of a millimetre, providing enhanced power. Moreover, the brakes have a toothed hub/friction disc connection with minimal circumferential backlash. Standard version is suitable for flange mounting and face mounting.

Request for a quote

ENGIFIELD - MECHANICAL POWER TRANSMISSION

Spain

Power off electromagnetic brake - spring applied (holding) is design to stop the movement when the electricity is off.

Request for a quote

KENDRION (VILLINGEN) GMBH

Germany

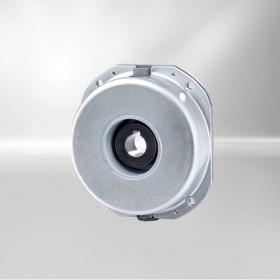

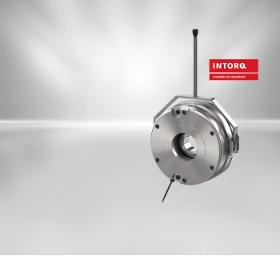

Do you need a spring-applied brake that reliably fulfills your desired basic functionality and can quickly be put to work? Then the BFK457 is the perfect match! The integrated fastening screws and fixed air gap ensure that it is easy to install. Its compact design helps to reduce costs and minimize installation space. further explanation: INTORQ BFK457 Compact — Braking torque range 0,12 Nm to 125 Nm INTORQ BFK457 Double-brake — 2x4 Nm to 2x125 Nm

Request for a quote

KENDRION (VILLINGEN) GMBH

Germany

High braking torque and small installation space: The compact and powerful BFK464-R dual-circuit spring-applied brake from INTORQ does it economically. This brake works with a split armature plate and two independent coil circuits. It reliably complies with the legal requirements for redundancy, such as for use in passenger elevators. In addition to the reliable braking torque, the high switching dynamics add even more safety. Switching noises are kept to a minimum. This is achieved by the well-engineered damping system. Another plus is the compact design: The rotor neck only minimally protrudes into the motor bearing shield, and the gear teeth of the rotor are particularly short.

Request for a quote

KENDRION (VILLINGEN) GMBH

Germany

High-performance drives are introducing completely new requirements for brake technology. On the one hand, the motor speeds and drive torques are constantly increasing. On the other hand, the installation space for the brake is shrinking. So, brakes are preferred which are both very efficient and require little space. The INTORQ BFK468 multi-pole spring-applied brakes meet precisely these requirements. Taking advantage of modern multi-coil technology, it reliably ventilates through its large air gap even when operating under strong forces. This level of performance is second to none!

Request for a quote

HENSE SYSTEMTECHNIK GMBH & CO. KG

Germany

The swivel motors with attached hydraulically released spring-applied multi-disc brake are recommended if a swivel position must remain unchanged once it has been reached – even over an unlimited period of time – despite the effect of a load torque. The brake is used solely to hold the load. It should only be noted that large transmission delays in the lines can cause time differences between the switching off of the swivel motor and the application of the released brake caused by spring force. In order to provide our customers with the right drive for all areas of application, the HSB swivel motor is available in a total of 5 different versions. We have listed the most important data below. You can find all further details in our data sheet.

Request for a quote

HENSE SYSTEMTECHNIK GMBH & CO. KG

Germany

The swivel motors with attached hydraulically released spring-applied multi-disc brake are recommended if a swivel position must remain unchanged once it has been reached – even over an unlimited period of time – despite the effect of a load torque. The brake is used solely to hold the load. It should only be noted that large transmission delays in the lines can cause time differences between the switching off of the swivel motor and the application of the released brake caused by spring force. In order to provide our customers with the right drive for all areas of application, the HSB swivel motor is available in a total of 5 different versions. We have listed the most important data below. You can find all further details in our data sheet.

Request for a quote

HENSE SYSTEMTECHNIK GMBH & CO. KG

Germany

The swivel motors with attached hydraulically released spring-applied multi-disc brake are recommended if a swivel position must remain unchanged once it has been reached – even over an unlimited period of time – despite the effect of a load torque. The brake is used solely to hold the load. It should only be noted that large transmission delays in the lines can cause time differences between the switching off of the swivel motor and the application of the released brake caused by spring force. In order to provide our customers with the right drive for all areas of application, the HSB swivel motor is available in a total of 5 different versions. We have listed the most important data below. You can find all further details in our data sheet.

Request for a quote

HENSE SYSTEMTECHNIK GMBH & CO. KG

Germany

The swivel motors with attached hydraulically released spring-applied multi-disc brake are recommended if a swivel position must remain unchanged once it has been reached – even over an unlimited period of time – despite the effect of a load torque. The brake is used solely to hold the load. It should only be noted that large transmission delays in the lines can cause time differences between the switching off of the swivel motor and the application of the released brake caused by spring force. In order to provide our customers with the right drive for all areas of application, the HSB swivel motor is available in a total of 5 different versions. We have listed the most important data below. You can find all further details in our data sheet.

Request for a quote

HENSE SYSTEMTECHNIK GMBH & CO. KG

Germany

The swivel motors with attached hydraulically released spring-applied multi-disc brake are recommended if a swivel position must remain unchanged once it has been reached – even over an unlimited period of time – despite the effect of a load torque. The brake is used solely to hold the load. It should only be noted that large transmission delays in the lines can cause time differences between the switching off of the swivel motor and the application of the released brake caused by spring force. In order to provide our customers with the right drive for all areas of application, the HSB swivel motor is available in a total of 5 different versions. We have listed the most important data below. You can find all further details in our data sheet.

Request for a quote

HENSE SYSTEMTECHNIK GMBH & CO. KG

Germany

The swivel motors with attached hydraulically released spring-applied multi-disc brake are recommended if a swivel position must remain unchanged once it has been reached – even over an unlimited period of time – despite the effect of a load torque. The brake is used solely to hold the load. It should only be noted that large transmission delays in the lines can cause time differences between the switching off of the swivel motor and the application of the released brake caused by spring force. In order to provide our customers with the right drive for all areas of application, the HSB swivel motor is available in a total of 5 different versions. We have listed the most important data below. You can find all further details in our data sheet.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

KENDRION (VILLINGEN) GMBH

Germany

Wherever there is only a very limited installation space available and a powerful brake is still required, we are sure to be “new fans”. Developed from the requirements of the industrial truck industry, the advantages of the BFK552 will certainly also make you curious in intralogistics and in the area of all general motor applications!

Request for a quote

KENDRION (VILLINGEN) GMBH

Germany

Wherever there is only a very limited installation space available and a powerful brake is still required, we are sure to be “new fans”. Developed from the requirements of the industrial truck industry, the advantages of the BFK551 will certainly also make you curious in intralogistics and in the area of all general motor applications!

Request for a quote

KENDRION (VILLINGEN) GMBH

Germany

The spring-applied brakes of the INTORQ BFK453 series were specially developed for use in industrial trucks. Particularly in reach trucks, they enable load-dependent braking or higher speeds. The latter results in shorter cycles and thus more efficient operations. What makes this fail safe brake particularly unique is the high braking torque and small installation space. The compact design means that lower access heights are possible on the industrial trucks, thus enabling much more ergonomic designs.

Request for a quote

KENDRION (VILLINGEN) GMBH

Germany

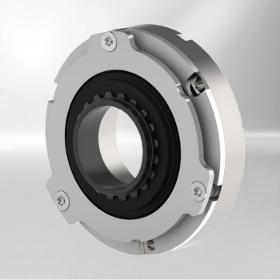

The BFK455 double-brake from INTORQ is a dual spring-applied brake with four friction surfaces and two electrically and mechanically separated brake circuits. The brake circuits can be individually controlled. Separate connecting lines can be used to control the brake circuits individually. The switching state of the two spring-applied brakes is monitored by two individual microswitches. The dual spring-applied brake is designed for one brake alone to provide the necessary braking torque. The second brake is used for redundancy, thus complying with the legal requirements for elevator standards. The BFK455 dual spring-applied brake from INTORQ is a redundant brake system with effective and stable noise reduction. It is ideally suited to elevator and platform applications.

Request for a quote

KENDRION (VILLINGEN) GMBH

Germany

Whenever the going gets tough, our BFK470 spring-applied brakes promise reliable performance. We have designed this IP66-sealed product line especially for dusty or humid operating conditions – such as wind power or crane facilities. Even extreme temperatures don't bother these brakes. They feature consistent protection and a unique modularity. You benefit from optimal versatility by using components which are freely configurable with each other. In other words, you get many variation options, all with rapid delivery times.

Request for a quote

KENDRION (VILLINGEN) GMBH

Germany

When operating in crane and port facilities, a braking system must primarily be reliably protected and, secondly, must operate very powerfully. The INTORQ BFK 471 product series combines these two features perfectly. These specially sealed brakes have a newly designed hand-release mechanism which, like the brakes themselves, is IP66 compliant. This series also features high braking torque and requires only a compact installation space.

Request for a quote

KENDRION (VILLINGEN) GMBH

Germany

Our versatile modular system ensures that the INTORQ BFK458 is a true all-around talent. It includes both standard solutions that can be used universally and specific solutions for special industry requirements. The highlight is the coordinated components that can be freely configured with each other. With this unique system developed by INTORQ, brakes can be assembled to fit almost any task. You benefit from the wide variety of options, fast project planning and rapid delivery. further explanation: INTORQ BFK458 Double-brake — Braking torques from 2 x 2 Nm to 2 x 600 Nm INTORQ BFK458 ATEX — Braking torques from 1,5 Nm to 600 Nm

Request for a quote

KENDRION (VILLINGEN) GMBH

Germany

The spring-applied brakes which are ideally suited for robotics is designed for robotics solutions and loads of up to appr. 20 kg, but it can also be used in other applications requiring small geometrical dimensions. With regard to their power density the slim single-disc brakes are flatter and lighter than the market standard, and due to their large inner diameter they are well suited for hollow-shaft drives. This makes them perfect for applications in lightweight robots with integrated drives. There is a growing demand for safety technology in order to avoid injuries by collisions, especially if the control technology or even the power supply fails. In this case electromagnetic brakes are usually the method of choice. As safety brakes they bring moving masses to a stop, keep loads in position and therefore prevent humans and material assets from being affected.

Request for a quote

OGE GROUP

Germany

Spring Applied Electric Brakes provide positive stopping and reliable holding of rotating devices on demand every time.

Request for a quoteResults for

Spring-applied brakes - Import exportNumber of results

27 ProductsCountries

Company type