- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- machines product

Results for

Machines product - Import export

INGENIERIA IRADI S.L.

Spain

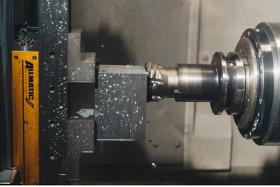

Machining according to drawing, from prototypes and unit batches to small and medium-sized production runs We specialize in serial production and machining of all components that require machining on lathes, milling machines, and machining centres.

Request for a quote

FORMEX MAQUINARIA

Spain

CLEANLY DOSES AND INJECTS FOOD MASSES OF DIFFERENT DENSITIES AND CHARACTERISTICS: viscous, liquid, soft, creamy, dense, sugary, etc. THE MIXTURE CAN HAVE SOLID PARTICLES INCORPORATED. For small and medium productions, although they can also be integrated into a working line or conveyor to achieve a higher degree of automation. IDEAL FOR DISPENSING PRODUCTS SUCH AS: muffins, plum-cakes, tartlets, custards, jams, sauces, fruit fillings, delicate fillings such as mousse, salad dressings, soups, Russian salad, creams with cereals, dairy products, etc. A WIDE RANGE OF ACCESSORIES AND DOSING OUTPUTS provide versatility when working with different products efficiently: mould conveyor, hose and hand gun, transfer pump, rotary cutting gun, injector nozzles, elevator, etc., elements that will make your work more precise.

Request for a quote

FORMEX MAQUINARIA

Spain

•Continuous dosing as the belt advances. •Manual adjustment of the dosing head height, which lowers automatically for each dose. •Adjustable belt speeds on the screen. •The dosing control is managed by a servomotor system that gives the machine greater speed, smoothness and precision to work with a wide variety of densities. •Thanks to the servomotor the user can control the dosage quantity electronically as well as loading and/or unloading speeds. •Anti-drip movement with suction of the product. •All this with great precision and with the facility to pre-record these parameters in more than 100 recipes.

Request for a quote

FORMEX MAQUINARIA

Spain

•You can dispense: bonbon, liqueur bonbon and praline bonbon. •The chocolate can have solid particles up to 3 mm thick. •Model manufactured according to production needs and adapted to the customer's moulds. •The dosing area, both the tank and the dosing nozzles, are heated to facilitate the hot dosing of the chocolate at an adjustable temperature, ensuring an ideal condition of the product. •Volumetric dosing. •The conveyor belt incorporates a vibration system at the product outlet to eliminate any bubbles that may have originated in the product during dosing. •Removable head for easy cleaning and with the possibility of being interchangeable. •A tray loader can be added at the beginning of the belt or a topping unit after dosing.

Request for a quote

FORMEX MAQUINARIA

Spain

WITH THIS MACHINE YOU WILL BE ABLE TO MAKE: Butter biscuits, almond doughs, curly biscuits, homemade biscuits, polvorones, perrunillas, mantecados, etc. •Uniform and fast production, avoiding punishing the dough or any alteration of its natural characteristics. •For medium and large productions, depending on the product and model. •Easy and quick change of moulds. •Intelligent production management by means of HMI panel, recipe programming. WIRE CUTTING AND MOULDS WITH A GREAT VARIETY OF SHAPES AND SIZES: For dense or hard doughs.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

STE TECPHARM

Spain

The OPTIMA TABLET COATER is a perforated coating pan designed for the film coating of tablets or pellets, suitable in aqueous and organic coatings, for the pharmaceutical industry. PATENTED COATING TECHNOLOGY THAT INCREASES THE BATCH SIZE RANGE FROM 10% TO 100% AND OPTIMIZES THE PARAMETER ADJUSTMENT FULLY AUTOMATICALLY. Its high technology allows an automatic adjustment control of the flow, avoiding the damp, saving coating and optimizing the processing time. Innovative high-quality equipment certified by accredited entities. Fully designed and built in Europe following regulatory requirements and GMP´s normative. The OPTIMA TABLET COATER controls each critical variable which is decisive for the dynamic equilibrium, such as: ■ Applied liquid flow. ■ Inlet airflow. ■ Exhaust airflow. ■ Inlet and exit air temperature. ■ Tablet temperature during the process. ■ Turning the speed of the pan drum.

Request for a quoteResults for

Machines product - Import exportNumber of results

7 ProductsCompany type

Category

- Machine tools, metal machining - parts and accessories (1)

- Machine tools - metal machining (1)

- Food industry - machinery and equipment (1)

- Cocoa and chocolate - machines and equipment (1)

- Food Processing (1)

- Biscuit making (1)

- Cakes and pastries, factory-baked (1)

- Chocolates, filled (1)

- Pharmaceutical industry - machinery and equipment (1)

- Plastic material processing (1)