- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- sheets

Results for

Sheets - Import export

APD MAQMASTER

Spain

MONOBLOCK WORK BASE. Monobloc cutting table construction system without screws or adjustments. MILLS AND CUTS IN THE SAME OPERATION. The TTRM-3x is the only one on the market capable of cutting and milling in the same operation, so the savings in downtime are substantial. IN THE TTRM-3X THE DISCS ARE NOT CHANGED FOR MILLING OR CUTTING. The cutting and milling head internally incorporates the two cutting and milling discs, therefore, no adjustments need to be made between operation changes. ERGONOMIC CONTROL PANEL WITH SELECTOR FOR CUTTING, MILLING OR BOTH SIMULTANEOUSLY. By turning a selector on the control panel, the operation to be carried out is selected without adjustments, without downtime. THE FEELING DISC VERY CLOSE TO THE MILLING DISC. (the distance between the feeler disc and the cutting disc is reduced to achieve simultaneous folding slots of less than 15mm, useful for making curvatures in the panel, etc.) DISTANCE FROM CUTTING DISC TO VARIABLE MILLING DISC.

Request for a quote

APD MAQMASTER

Spain

Length TTRM 1500 = 4050 mm Height TTRM 1500 = 2450 mm Width TTRM 1500 = 1260 mm Horizontal Cut TTRM1500 = 3000 mm Vertical Cut TTRM 1500 =1500 mm Length TTRM 2100 = 5050 mm Height TTRM 2100 = 3100 mm Width TTRM 2100 = 1460 mm Horizontal Cut TTRM 2100 = 4000 mm Vertical Cut TTRM 2100 = 2100 mm Cutting depth 90 mm Disc diameter 350 mm Voltage 230 / 400V – 50 Hz Power 3CV RPM 3000 OPTIONAL Support rollers Probe system for alucobom. Vertical digital display. Horizontal digital display.

Request for a quote

APD MAQMASTER

Spain

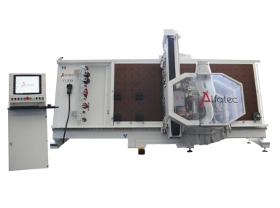

X axis (Longitudinal) 2000 mm Y axis (Horizontal) 4000 mm Z axis (Vertical) – without milling 300 mm POSITIONING DISTANCES X axis (Longitudinal) 108m/dK Y axis (Horizontal) 108m/dK Z axis (Vertical) 10.5m/dK SPINDLE 7.5/9kW fan cooled spindle Maximum power 24000 rpm Maximum rotation speed ISO 30 Tool holders Electric fan TOOLS MAGAZINE Automatic umbrella type tool magazine system Maximum number of tools 10 Maximum disc diameter that can be loaded into the magazine system 150 mm Maximum dimensions of tools that can be loaded in the magazine system 140 mm Diameter / 120 mm Length Number of angled heads that can be loaded into the magazine system 2 OPERATIONAL AREA Vacuum table system with automatic zoning Vacuum table tube dimensions 269 mm * 2000 mm Number of externally controlled vacuum modules 7 X axis reference support 1 And axis reference support 4 Automatic tool length measurement Possibility of operation in two stations

Request for a quote

APD MAQMASTER

Spain

X axis (Longitudinal) 2000 mm Y axis (Horizontal) LEPUS II 4000 mm – LEPUS II L 7000 mm Z axis (Vertical) – without milling 200 mm POSITIONING DISTANCES X axis (Longitudinal) 55 m /dK Y axis (Horizontal) 55 m /dK Z axis (Vertical) 15 m /dK SPINDLE Spindle cooled by 4 fans Maximum power 2.2 kW Maximum rotation speed 18000 rpm ER20 tool holder CONTROL UNIT CNC control Remote network connection, data transfer via Ethernet and USB. OPERATIONAL AREA Dust and chip aspiration system Suction areas in independent spaces Externally controlled vacuum tables LAPUS II 6 – LAPUS II L 8 Automatic tool length measurement Possibility of doing double station processing X axis reference support Y axis reference support LEPUS II 4 – LEPUS II L 9 Metal fences closed on three sides that prevent access to the work area

Request for a quote

APD MAQMASTER

Spain

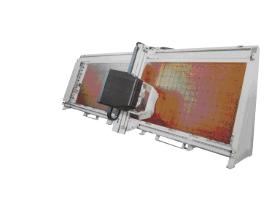

The PLC 3000 Folder is the ideal solution for those looking to fold aluminum sheet efficiently and accurately. With its ergonomic design and robust construction, this folder delivers exceptional performance in every operation. Thanks to its manual design, the PLC 3000 Folder gives the operator complete control over the folding process. Its ease of maneuver allows quick and precise adjustments, guaranteeing bends with constant and uniform radii on the 1.2 mm aluminum sheet. The PLC 3000 Folder is equipped with features that improve its performance and facilitate its use. Its sheet metal clamping system ensures a firm and stable fixation during folding, preventing slipping and ensuring consistent results. In addition, it has adjustable length stops, which allows folding with precise and repeatable measurements. These stops facilitate serial work and speed up the production process, saving time and increasing efficiency.

Request for a quote

APD MAQMASTER

Spain

Manual override Folds composite panels quickly and efficiently, reducing downtime. Continuous and equal folds, the design of the folder guarantees uniform pressure along the entire length of the fold, regardless of its dimensions. Manufactured in 4 or 5 meters in length. It can be manufactured to the size desired by the client upon request.

Request for a quote

APD MAQMASTER

Spain

It has a fixed 8-position tool changer and a carriage to which another tool changer can be attached, always with 8 positions. Thanks to its numerous versions, 1500×3000, 1650×4000, 1650×6000, 2000x 4000 and 2000×8000, the PWI has found various applications in the industrial sector, for example in plastics, aluminum and agglomerates in general. Special versions can be supplied for milling and threading steel profiles and/or bars. PWI offers a wide Z to hold i supports and to hold particular profiles. In its complete version with clamps, it allows alternating compounds and profiles, in order to optimize the machine for different applications in a single work environment. This machine is usually chosen for its versatility and speed, with an interpolation of up to 40 m/min. In this case, CADCAM ITALMAC provides this version of CNC with all the DXF and geometric figure import tools, so that the PWI is recognizable compared to other similar machines.

Request for a quote

APD MAQMASTER

Spain

Vertical CNC woodworking machines with closed table. Vertical CNC machines with three, four and five controlled axes equipped with a fixed Bakelite work table. Suitable for any type of processing, recommended for those who work a lot of panels, since the closed top technology allows both suction cup and nesting operations

Request for a quote

APD MAQMASTER

Spain

Three, four and five controlled axis configurations Bakelite work surface Extreme versatility to adapt to different materials such as PVC and plexiglass Working ranges: 3500×1600 – 2000 mm, 5000×1600 – 2000 mm, 6000×1600 – 2000 mm Work areas divided into 6/8/10 vacuum zones, automatically activated by the software according to the dimensions of the processed panels Benefits: Speed and precision in CNC machining of aluminum panels Greater comfort and productivity for operators Significant space savings compared to horizontal machines Versatility to work with a wide range of materials

Request for a quote

APD MAQMASTER

Spain

Fixed Bakelite work table: Robust and resistant, ideal for demanding jobs. Closed table technology: Allows both suction cup and nesting operations, optimizing your workflow. Controlled axes: Three, four or five axes for greater precision and flexibility in your projects. Suitable for any type of processing: Perfect for cutting, milling, drilling and much more. Ideal for working with panels Horizontal CNC machines with a closed table are especially recommended for those working with wooden panels, as the closed top technology allows for safe and precise clamping using suction cups or sockets.

Request for a quote

APD MAQMASTER

Spain

Tank (liters) 270 liters Aspirated Air (liters/min) 653 liters minute Power (HP/KW) 5.5 hp – 4 kw Head Rotation Speed (rpm) 1,400 rpm Power (V/phase/Hz) 400/3/50 Sound level dB(A) dB (WA) 77 – 97 dB Pressure (bar) 11 bar Dimensions (mm) 1,575 x 680 x 1,150 Weight (Kg) 167 kilos

Request for a quote

VINCO

Spain

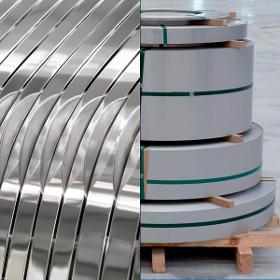

THICKNESS TOLERANCES: According to the EN 10140:2006 Standard. Specified thickness tolerances for cold rolled strip and strip obtained strapping wide precision rolling w. WIDTH TOLERANCES: Width tolerances according to the EN 10140 Standard for nominal widths Other, closer dimensional tolerances are possible under a commercial agreement LENGTH TOLERANCES: According to the EN1040 Standard. Other tolerances are possible under a commercial agreement EDGE CAMBER TOLERANCES: Edge curve tolerances according to the EN 10140 Standard Other edge curve tolerances possible under a commercial agreement RIPPLE - LONGITUDINAL FLATNESS The flatness tolerance of the strips in cut lengths in the direction of rolling must be a maximum of 10 mm over 1000 mm. Any other flatness requirement must be agreed when placing the order.

Request for a quote

VINCO

Spain

THICKNESS TOLERANCES: According to the EN 10140:2006 Standard. Specified thickness tolerances for cold rolled strip and strip obtained strapping wide precision rolling w. WIDTH TOLERANCES: Width tolerances according to the EN 10140 Standard for nominal widths Other, closer dimensional tolerances are possible under a commercial agreement LENGTH TOLERANCES: According to the EN1040 Standard. Other tolerances are possible under a commercial agreement EDGE CAMBER TOLERANCES: Edge curve tolerances according to the EN 10140 Standard Other edge curve tolerances possible under a commercial agreement RIPPLE - LONGITUDINAL FLATNESS The flatness tolerance of the strips in cut lengths in the direction of rolling must be a maximum of 10 mm over 1000 mm. Any other flatness requirement must be agreed when placing the order.

Request for a quote

VINCO

Spain

THICKNESS TOLERANCES: According to the EN 10140:2006 Standard. Specified thickness tolerances for cold rolled strip and strip obtained strapping wide precision rolling w. WIDTH TOLERANCES: Width tolerances according to the EN 10140 Standard for nominal widths Other, closer dimensional tolerances are possible under a commercial agreement LENGTH TOLERANCES: According to the EN1040 Standard. Other tolerances are possible under a commercial agreement EDGE CAMBER TOLERANCES: Edge curve tolerances according to the EN 10140 Standard Other edge curve tolerances possible under a commercial agreement RIPPLE - LONGITUDINAL FLATNESS The flatness tolerance of the strips in cut lengths in the direction of rolling must be a maximum of 10 mm over 1000 mm. Any other flatness requirement must be agreed when placing the order.

Request for a quote

VINCO

Spain

THICKNESS TOLERANCES: According to the EN 10140:2006 Standard. Specified thickness tolerances for cold rolled strip and strip obtained strapping wide precision rolling w. WIDTH TOLERANCES: Width tolerances according to the EN 10140 Standard for nominal widths Other, closer dimensional tolerances are possible under a commercial agreement LENGTH TOLERANCES: According to the EN1040 Standard. Other tolerances are possible under a commercial agreement EDGE CAMBER TOLERANCES: Edge curve tolerances according to the EN 10140 Standard Other edge curve tolerances possible under a commercial agreement RIPPLE - LONGITUDINAL FLATNESS The flatness tolerance of the strips in cut lengths in the direction of rolling must be a maximum of 10 mm over 1000 mm. Any other flatness requirement must be agreed when placing the order.

Request for a quote

VINCO

Spain

THICKNESS TOLERANCES: According to the EN 10140:2006 Standard. Specified thickness tolerances for cold rolled strip and strip obtained strapping wide precision rolling w. WIDTH TOLERANCES: Width tolerances according to the EN 10140 Standard for nominal widths Other, closer dimensional tolerances are possible under a commercial agreement LENGTH TOLERANCES: According to the EN1040 Standard. Other tolerances are possible under a commercial agreement EDGE CAMBER TOLERANCES: Edge curve tolerances according to the EN 10140 Standard Other edge curve tolerances possible under a commercial agreement RIPPLE - LONGITUDINAL FLATNESS The flatness tolerance of the strips in cut lengths in the direction of rolling must be a maximum of 10 mm over 1000 mm. Any other flatness requirement must be agreed when placing the order.

Request for a quote

VINCO

Spain

THICKNESS TOLERANCES: According to the EN 10140:2006 Standard. Specified thickness tolerances for cold rolled strip and strip obtained strapping wide precision rolling w. WIDTH TOLERANCES: Width tolerances according to the EN 10140 Standard for nominal widths Other, closer dimensional tolerances are possible under a commercial agreement LENGTH TOLERANCES: According to the EN1040 Standard. Other tolerances are possible under a commercial agreement EDGE CAMBER TOLERANCES: Edge curve tolerances according to the EN 10140 Standard Other edge curve tolerances possible under a commercial agreement RIPPLE - LONGITUDINAL FLATNESS The flatness tolerance of the strips in cut lengths in the direction of rolling must be a maximum of 10 mm over 1000 mm. Any other flatness requirement must be agreed when placing the order.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

VINCO

Spain

TYPE OF PROCESS ROUTE AND SURFACE FINISH OF PLATES AND COILS EN 10088-2: 2H, 2D, 2B, 2R, 2G, 2J, 1D, 2E, 2K. Tinned or nickel plated strips can be supplied under a commercial agreement. The quality of the surface of a strip is characterised by the following approximate average surface roughness values: Ra < 0.3 µm for tensile strength levels of +C1150 and above. Ra < 0.5 µm for tensile strength levels ranging from +C700 to +C1000.

Request for a quote

VINCO

Spain

TYPE OF PROCESS ROUTE AND SURFACE FINISH OF PLATES AND COILS EN 10088-2: 2H, 2D, 2B, 2R, 2G, 2J, 1D, 2E, 2K. Tinned or nickel plated strips can be supplied under a commercial agreement. The quality of the surface of a strip is characterised by the following approximate average surface roughness values: Ra < 0.3 µm for tensile strength levels of +C1150 and above. Ra < 0.5 µm for tensile strength levels ranging from +C700 to +C1000.

Request for a quote

VINCO

Spain

BARE MATERIAL The strips must be clean and free of detrimental defects, which must be specified by agreement between the customer and the supplier when requesting the quote and in the order. Normally, a small residual layer of lubricant is left on cold-rolled products, which is authorised unless otherwise specified. ROUGHNESS EN 1654 This must be agreed between the customer and the supplier when requesting the quote and confirming the order. SURFACE CONDITION EN 13599 The strips must be clean and free of detrimental defects, which must be specified by agreement between the customer and the supplier in the request for quotes and in the order. Normally, a small residual layer of lubricant is left on cold-drawn products, and this is acceptable unless otherwise specified. Discolouration is acceptable, provided that it is not detrimental to the use of the product. TIN COATINGS Tin coatings for strips and copper strips and copper alloys: Electrolytic s/EN 14436 and Hot dip s/EN 13148

Request for a quote

VINCO

Spain

BARE MATERIAL The strips must be clean and free of detrimental defects, which must be specified by agreement between the customer and the supplier when requesting the quote and in the order. Normally, a small residual layer of lubricant is left on cold-rolled products, which is authorised unless otherwise specified. ROUGHNESS EN 1654 This must be agreed between the customer and the supplier when requesting the quote and confirming the order. SURFACE CONDITION EN 13599 The strips must be clean and free of detrimental defects, which must be specified by agreement between the customer and the supplier in the request for quotes and in the order. Normally, a small residual layer of lubricant is left on cold-drawn products, and this is acceptable unless otherwise specified. Discolouration is acceptable, provided that it is not detrimental to the use of the product. TIN COATINGS Tin coatings for strips and copper strips and copper alloys: Electrolytic s/EN 14436 and Hot dip s/EN 13148

Request for a quote

VINCO

Spain

BARE MATERIAL The strips must be clean and free of detrimental defects, which must be specified by agreement between the customer and the supplier when requesting the quote and in the order. Normally, a small residual layer of lubricant is left on cold-rolled products, which is authorised unless otherwise specified. ROUGHNESS EN 1654 This must be agreed between the customer and the supplier when requesting the quote and confirming the order. SURFACE CONDITION EN 13599 The strips must be clean and free of detrimental defects, which must be specified by agreement between the customer and the supplier in the request for quotes and in the order. Normally, a small residual layer of lubricant is left on cold-drawn products, and this is acceptable unless otherwise specified. Discolouration is acceptable, provided that it is not detrimental to the use of the product. TIN COATINGS Tin coatings for strips and copper strips and copper alloys: Electrolytic s/EN 14436 and Hot dip s/EN 13148

Request for a quote

VINCO

Spain

BARE MATERIAL The strips must be clean and free of detrimental defects, which must be specified by agreement between the customer and the supplier when requesting the quote and in the order. Normally, a small residual layer of lubricant is left on cold-rolled products, which is authorised unless otherwise specified. ROUGHNESS EN 1654 This must be agreed between the customer and the supplier when requesting the quote and confirming the order. SURFACE CONDITION EN 13599 The strips must be clean and free of detrimental defects, which must be specified by agreement between the customer and the supplier in the request for quotes and in the order. Normally, a small residual layer of lubricant is left on cold-drawn products, and this is acceptable unless otherwise specified. Discolouration is acceptable, provided that it is not detrimental to the use of the product. TIN COATINGS Tin coatings for strips and copper strips and copper alloys: Electrolytic s/EN 14436 and Hot dip s/EN 13148

Request for a quote

VINCO

Spain

EN AW-3003 (Al Mn1Cu) - EN 485 0/H111 EN 485 EN AW-3003 (Al Mn1Cu) - EN 485 H14 EN 485 EN AW-3003 (Al Mn1Cu) - EN 485 H16 EN 485 EN AW-3003 (Al Mn1Cu) - EN 485 H18 EN 485 EN AW-3003 (Al Mn1Cu) - EN 485 H24 EN 485 EN AW-3003 (Al Mn1Cu) - EN 485 H26 EN 485 EN AW-3005 (Al Mn1Mg0,5) - EN 485 H111 EN 485 EN AW-3005 (Al Mn1Mg0,5) - EN 485 H14 EN 485 EN AW-3005 (Al Mn1Mg0,5) - EN 485 H22 EN 485 EN AW-3005 (Al Mn1Mg0,5) - EN 485 H24 EN 485 EN AW-3105 (Al Mn0,5Mg0,5) - EN 485 H111 EN 485 EN AW-3105 (Al Mn0,5Mg0,5) - EN 485 H18 EN 485 EN AW-3105 (Al Mn0,5Mg0,5) - EN 485 H24 EN 485"

Request for a quote

VINCO

Spain

EN AW-5005 (Al Mg1(B) EN AW-5052 (Al Mg2,5) EN AW-5083 (Al Mg4,5Mn0,7) EN AW-5086 (Al Mg4) EN AW-5182 (Al Mg4,5Mn0,4) EN AW-5657 (Al 99,85 Mg1(A) EN AW-5754 (Al Mg3) / EN 485 series

Request for a quote

VINCO

Spain

EN AW-6016 (Al Si1,2Mg0,4) - EN 485 T4 EN 485 EN AW-6016 (Al Si1,2Mg0,4) - EN 485 T6 EN 485 EN AW-6082 (Al Si1MgMn) - EN 485 O EN 485 EN AW-6082 (Al Si1MgMn) - EN 485 T4 EN 485 EN AW-6082 (Al Si1MgMn) - EN 485 T6 EN 485 EN AW-7075 (Al Zn5,5MgCu) - EN 485 O EN 485 EN AW-7075 (Al Zn5,5MgCu) - EN 485 T6 EN 485 EN AW-7075 (Al Zn5,5MgCu) - EN 485 T76 EN 485 EN AW-7075 (Al Zn5,5MgCu) - EN 485 T73 EN 485 EN AW-8011A (Al FeSi(A)) - EN 485 O/H111 EN 485 EN AW-8011A (Al FeSi(A)) - EN 485 H18 EN 485 EN AW-8011A (Al FeSi(A)) - EN 485 H24 EN 485 FINISHES: Under a commercial agreement We are able to supply aluminium that can be anodised or is anodised We also offer the following material cleaning options (depending on the alloy): Wash Chemical degreasing

Request for a quote

VINCO

Spain

AW-2017A (Al Cu4MgSi(A)) - EN 485 O EN 485 AW-2017A (Al Cu4MgSi(A)) - EN 485 T4 EN 485 AW-2024 (Al Cu4Mg1) - EN 485 O EN 485 AW-2024 (Al Cu4Mg1) - EN 485 T4 EN 485

Request for a quote

VINCO

Spain

EN AW-1050A (Al 99,5) - EN 485 0/H111 EN 485 EN AW-1050A (Al 99,5) - EN 485 H14 EN 485 EN AW-1050A (Al 99,5) - EN 485 H16 EN 485 EN AW-1050A (Al 99,5) - EN 485 H18 EN 485 EN AW-1050A (Al 99,5) - EN 485 H22 EN 485 EN AW-1050A (Al 99,5) - EN 485 H24 EN 485 EN AW-1050A (Al 99,5) - EN 485 H26 EN 485 EN AW-1070 (Al 99,7) - EN 485 0/H111 EN 485 EN AW-1070 (Al 99,7) - EN 485 H18 EN 485 EN AW-1070 (Al 99,7) - EN 485 H22 EN 485 EN AW-1070 (Al 99,7) - EN 485 H24 EN 485 EN AW-1200 (Al 99,0) - EN 485 0/H111 EN 485 EN AW-1200 (Al 99,0) - EN 485 H14 EN 485 EN AW-1200 (Al 99,0) - EN 485 H18 EN 485 EN AW-1200 (Al 99,0) - EN 485 H19 EN 485 EN AW-1200 (Al 99,0) - EN 485 H24 EN 485 FINISHES: Under a commercial agreement We are able to supply aluminium that can be anodised or is anodised We also offer the following material cleaning options (depending on the alloy): Wash Chemical degreasing

Request for a quote

VINCO

Spain

BARE MATERIAL The strips must be clean and free of detrimental defects, which must be specified by agreement between the customer and the supplier when requesting the quote and in the order. Normally, a small residual layer of lubricant is left on cold-rolled products, which is authorised unless otherwise specified. ROUGHNESS EN 1654 This must be agreed between the customer and the supplier when requesting the quote and confirming the order. SURFACE CONDITION EN 13599 The strips must be clean and free of detrimental defects, which must be specified by agreement between the customer and the supplier in the request for quotes and in the order. Normally, a small residual layer of lubricant is left on cold-drawn products, and this is acceptable unless otherwise specified. Discolouration is acceptable, provided that it is not detrimental to the use of the product. TIN COATINGS Tin coatings for strips and copper strips and copper alloys: Electrolytic s/EN 14436 and Hot dip s/EN 13148

Request for a quoteResults for

Sheets - Import exportNumber of results

64 ProductsCompany type