- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- solvent cleaning

Results for

Solvent cleaning - Import export

ROVIMEX BATTERY AND ENERGY TECHNOLOGIES

Turkey

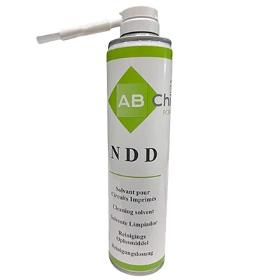

100% ozone friendly solvent - meaning zero ODP. Excellent removal of greases, oils and flux residues and acrylic protective coatings from printed circuit boards (PCBs) Leaves a perfectly clean, dry surface – traditional solvents often leave it greasy. It is harmless to most plastics, rubbers, elastomers and surface coatings. NDD is compatible with a wide range of plastics.

Request for a quote

PERO AG

Germany

Acidic, neutral or alkaline wet media Aqueous media remove dirt particles from surfaces and rinse them off. Aqueous detergents disperse particles, and form or separate emulsions. They act on the surfaces of parts. If required, aqueous media can be used to alter the surface properties of parts by passivation (phosphatising), pickling, etc. In all applications, the treatment of the medium itself is of crucial importance. Aqueous media are powerful detergents. Solvents are wet media that are able to dissolve substances without actually reacting with them. The most commonly used cleaning solvents are hydrocarbons and modified alcohols with a flash point > 55°C, and halogenated hydrocarbons. Solvents remove dirt particles from surfaces and rinse them off. Advantages Short cycle times, energyefficient drying, low solvent consumption, long medium service life and easy treatment.

Request for a quote

PERO AG

Germany

The modular, preassembled PERO S1 units are available at short notice for your specific application The compact S1 degreases and cleans components made from various materials and of many different geometries and degrees of machining. The S1 is designed for dirt and grease removal at low energy and resource consumption. It therfore is the ideal entrylevel unit for cleaning with solvents in a closed system. The integrated distilling unit ensures process safety and efficient cleaning at a consistently high level. Cleaning with hydrocarbons or modified alcohols with a flash point > 55°C; other solvents on request 530 x 320 x 200 mm or 530 x 365 x 250 mm Entrylevel mpdel for cleaning with solvent in closed system Configurable for short cycle times Vapour degreasing in 1st process step Available as 1bath unit with loading of the unit via Manual charging unit Automatic charging unit

Request for a quote

NOVA KIMYA

Turkey

Usage Areas and Features: It can be used safely on all kinds of oily surfaces such as kitchen, bathroom, carpet, armchair, metal, car, leather, etc. It is the ideal type cleaner for hospitals, hotels, factories, restaurants, auto services and homes. Used by diluting 1-20 times in vehicle glove box and glass cleaning. It is a product made from solvents and surfactants. It penetrates, loosens and dissolves burnt and oil residues very strongly. The residues are removed by rinsing. It does not leave any bad odor and residue, it is not flammable. It is applied with hot and cold water.

Request for a quote

OKS SPEZIALSCHMIERSTOFFE GMBH

Germany

Grease lubrication of unsheltered parts subject to heavy loading and/or impacts, such as friction, rolling and pivoting bearings, splined shafts, knockout spindles, threaded spindles and sliding surfaces of all kinds For harsh operating conditions Advantages and benefits Excellently suited as a safety lubricating grease in mixed friction sector with especially good wear protection Effectively protects against corrosion Contains Mox-active to improve performance For best results clean the lubricating point carefully. Clean with solvents like OKS 2610/OKS 2611 Universal Cleaner. Remove the corrosion protection ahead of the initial filling. Fill the bearings in a way that all the functional surfaces for sure get the grease. Slow moving bearings(DN-value < 50,000) should be filled completely, normal moving bearings should be filled to 1/3 of the free inner housing space. Observe the instructions of the bearing or machine manufacturer. Relubrication with a grease gun on to the grease

Request for a quote

OKS SPEZIALSCHMIERSTOFFE GMBH

Germany

Grease lubrication of plain and rolling bearings at high temperatures, e.g. in painting and drying ovens, converters, pouring ladles, heating systems, hot-air fans, charging cranes, vulcanising systems and electric motors Advantages and benefits Excellently suited for long-term lubrication of grease lubricating points subject to high-temperature loading Highly effective due to optimum solid lubricant formula Broad range of uses above normal grease performance areas Reduced maintenance and lubricant costs due to possible safety lubrication Drip-free hot bearing grease for long-term and safety lubrication in a broad temperature range For best results clean the lubricating point carefully. Clean with solvents like OKS 2610/OKS 2611 Universal Cleaner. Remove the corrosion protection ahead of the initial filling. Fill the bearings in a way that all the functional surfaces for sure get the grease.

Request for a quote

WALTER SCHMIDT CHEMIE GMBH

Germany

The all-rounder for household, leisure, car and trade. For cleaning windows, tiles, tiles, glass and chrome. Brings shine to the kitchen, bathroom and toilet. As fuel for fondue preparation and for camping stoves. Can also be used by industry and hobbyists as a solvent or for cleaning in the trade. Available in two different qualities: standard quality and odorless premium quality. Other sizes available on request

Request for a quote

GLOBAL GASES GROUP THAI CO LTD

Thailand

Refrigerant gas R141b solvent, used in cleaning systems and as a refrigerant under the names R-141b or HCFC-141b. 1,1-Dichloro-l-fluoroethane is a haloalkane with the formula C2H3CI2F. It is one of the three isomers of dichlcrofluoroethane. it's a replacement for R11.

Request for a quote

CDA

France

CDA’s Ninon Wrap is an automatic linear labelling machine that employs the adhesive banding/wrap-around labelling technique to label cylindrical products of various sizes. This linear automatic labeller combines a high labelling rate of up to 200 products per minute with exceptional application accuracy. The Ninon Wrap stands out for its user-friendly operation facilitated by an intuitive touch screen and straightforward adjustment. This automatic labelling machine is well-suited for diverse sectors of activity, including: Brewery (beer bottles 25 cl, 33 cl, etc.), Cosmetics (ointment, liquid soap, shampoo, moisturizing products, shower gel, etc.), Food processing (canned fruit and vegetables, sauce, condiments, jam, honey, marmalade, etc.), Chemistry (cleaning products, solvent, motor oil, detergent, etc.), Paint and varnish (pots, seals, cans), etc.

Request for a quote

INTEGRATED CHEMICALS SPECIALTIES

Netherlands

Solvents for applications like: cosmetics, cleaning, coatings and polyurethanes.

Request for a quote

CDI VALLÈS S.L.

Spain

Concentrated chlorinated detergent for agricultural and livestock industries PC35 Washing and cleaning products (including products containing solvents) Powerful detergent, cleans and deodorises in one step. Its special foaming formulation facilitates wetting and thus the detergency process. Does not attack steel, stainless steel, enamelled ceramics or plastics, but should be used at low temperatures and short contact times on aluminium surfaces. It contains alkaline degreasers and surfactants, complexing agents and active chlorine, so it is particularly suitable for the removal of organic residues such as grease, proteins and blood adhering to all types of surfaces. Due to these properties, it is recommended for use in foam projection cleaning.

Request for a quote

CDI VALLÈS S.L.

Spain

Farmyard floor degreaser PC35 Washing and cleaning products (including products containing solvents) Powerful degreaser for deep cleaning of hard floors. Specially formulated to combine maximum cleaning power with anti-foaming and anti-corrosion properties required for use on heavy duty floors such as farm and livestock environments. Suitable for the removal of all types of grease and other organic fouling. Cleaning and degreasing of hard floors on all types of floors in pig farms, poultry farms, etc., can be applied either by scrubbing machine or manually.

Request for a quote

REA ELEKTRONIK GMBH

Germany

REA JET´s HR product family offers high resolution coding and marking systems using especially developed inks to facilitate clean, environmentally-friendly and solvent-free marking on even non-porous surfaces. HR systems are maintenance-free. With each cartridge change a new print-engine is in place. The REA JET HR is designed for endusers for installation right at the production line. Applications — Protection against counterfeiting and traceability — Ideally suited for serialization and track & trace applications — For absorbent and non-absorbent surfaces — Alphanumeric texts, barcodes, 2D codes, Data Matrix codes and logos — Variable data such as date, time, counter, shift code, database contents — Highest print resolution up to 600 dpi, configurable in 16 levels

Request for a quote

JADAM

Portugal

White spirit, mineral spirits, or mineral turpentine, turpentine substitute, petroleum spirits, is a petroleum-derived clear liquid used as a common organic solvent in painting White spirit is often used as a paint thinner The word "mineral" in "mineral spirits" or "mineral turpentine" is to distinguish it from distilled spirits (alcoholic beverages) or from true turpentine (distilled tree resin) It is insoluble in water and used as an extraction solvent, as a cleaning solvent, as a degreasing solvent and as a solvent in aerosols, paints, lacquers, varnishes, and asphalt products Uses: Degreasing and lubricating, Solvent and paint thinner,Portable stoves Industries: Household chemicals,Painting materials,Hydrocarbon solvents,Dry cleaning Properties: Initial boiling point (IBP) 145–174°C Final boiling point (IBP+21)°C Average relative molecular mass 150 Relative density 0.780 @15°C Flash point 31–54°C Solubility in water (w) < 0.1% CAS Number 64741-92-0 EC Number 232-489-3 UN no. 1268

Request for a quote

DISTRIBUCIONES JULMARSA S.L.

Spain

Green Polyester film, single coated with a rubber resin pressure sensitive adhesive. APPLICATIONS Masking in powder coating applications. Protects large areas of circuit boards from chemicals fumes or splashes. Masking of circuit boards during solder stripping and nickel/gold plating of contact fingers. PRODUCT BENEFITS Resists baking temperatures of 170°C to 190°C during 20min. Operating temperature range: ‐30°C to 130°C. Eliminates silicone contamination and need for PCB cleaning solvents. Easy application and removal. Non‐silicone adhesive removes cleanly. Good adhesion to substrate. Excellent conformability.

Request for a quote

SAMES KREMLIN

France

Automatic Cleaning System for the applicator spray head Description Automatic cleaning of the contamination on the atomizer. It is specially designed for atomizers like ACCUBELL® and PPH models (equipped with all the existing types of bells : ø35 mm, ø50 mm, ø65 mm or ø80mm). Performance Air shroud cleaning device for a steady application Air/material cyclonic separator Productivity Increase your working time by reducing production stops Automatic process managed by paint automation Sustainability Reclaiming all cleaning material Operators spend less time cleaning with solvent

Request for a quote

WEESAFE

France

WeeTex Max is a high performance of wiping that’s ideal for applying or cleaning all of petroleum based products. They are especially effective in low linting applications where cleaning solvents are used to clean or prepare a surface. This wiper has a good capacity for absorbing oil based liquids 75 GM2 – Polypropylene

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

PNZ-PRODUKTE GMBH

Germany

Suitable for dilution of all solvent-based products. Brush Cleaner cleans and degreases tools, machines and dirty substrates.

Request for a quote

PNZ-PRODUKTE GMBH

Germany

Suitable for thinning of all solvent-based products. Special Thinner cleans and degreases tools, machines and soiled substrates. Also suitable for deresination of surfaces (among others larch, pine).

Request for a quote

DE SMET ENGINEERS & CONTRACTORS

Belgium

De Smet Engineers & Contractors has been involved in all steps of the production of vegetable oils from oilseeds crushing for the construction of Edible Oils Plants; in this article you will find a more detailed understanding about the process of vegetable oil extraction: First step: Preparation of the oil containing material prior to solvent extraction Cleaning and Drying The plant feedstock must be cleaned so that foreign matters are removed. This applies particularly to sand/silicate and iron which may damage the preparation plant equipment. For some seeds or for some processes the incoming material moisture must be controlled and adjusted for better efficiency of subsequent operations. Mechanical preparation Most of raw materials needs to broken to reduce the particle size to ensure proper cooking and flaking. They are then heated in cooking / conditioning equipment and their moisture further controlled in addition to be softened before the next mechanical operations. After cooking, heated grits are flaked so that the oil cells are broken and the oil more readily available for further solvent extraction or mechanical pressing. Pressing Oilseeds containing above 20 to 25% (rapeseed, sunflower seeds, cottonseeds...) are generally pressed mechanically in order to extract most or part of the oil available in the feedstock. This operation is done through full pressing for maximum oil recovery leaving up to 5 to 10% in the final cake which is marketed as such or through a low pressure pre-pressing operation producing a cake with higher residual oil content which is then recovered in the solvent extraction plant. Dehulling Oil extraction plants produce a solid finished product in addition to the extracted oil; this product (cake or meal) is normally used as an important component for animal feed recipes. Depending on the meal destination, its protein content often needs to be increased and its fibre content minimized. Such characteristics are generally achieved through decortication or dehulling operations that separate the outer part of the feedstock before extracting the oil. Second step: Solvent extraction of the material suitably prepared Extraction In the solvent extractor, solids (Flakes from the flaking machines or cakes from the pre-presses) are conveyed through the equipment while a mixture of hexane and oil (miscella) is sprayed counter-current. The extractor produces therefore deoiled solids containing solvent and miscella. Desolventization Deoiled solids coming out of the extractor are conveyed to a dedicated equipment that completely removes the remaining solvent while preserving the meal quality: the desolventizer. This apparatus is usually combined with additional sections for drying and cooling the meal to the required storage and market parameters. Miscella distillation Solvent contained in the miscella is completely removed under vacuum and optimum temperature for preserving oil quality. The solvent from the distillation as well as the one removed at meal desolventization stage are then recycled to the extractor. Solvent recovery Since the air entering the process together with material fed to the extractor is laden with solvent when it is removed from the plant it first pass through a specially designed absorption column to limit emission to an acceptable level. Meal treatment The extracted meal is often subject for further treatment, including grinding to obtain the required granulometry or pelletizing to reduce its volume during transport.

Request for a quote

LUBCON LUBRICANTS UK LTD

United Kingdom

Cleaning and maintenance of a machine is essential for long and reliable operation. LUBCON has a wide product range of cleaning agents and solvents for industrial uses as well as for application in the food and packaging sector. Whether industrial, biodegradable cleaners or a sugar-dissolving lubricant for clean and residue-free surfaces, we have the solution for almost every application.

Request for a quote

KLN ULTRASCHALL AG

Germany

Solvent cleaning machines / non-flammable solvent Compact • Standard with Automation • Freely programmable • Ultrasound and Agitation • Vapor Rinse • Freebord drying • Non-flammable Solvents • Meets YOUR BUDGET with Premium Features

Request for a quote

KLN ULTRASCHALL AG

Germany

KLN manufactures various cleaning machines acc. to ATEX (ATmosphère EXplosibles) for the use of combustible liquids. The cleaning machines can be used separately or in combination with other methods. The cleaning tanks must be operated at a well ventilated place. The combustible cleaning agent can be filled in directly into the tanks. The ultrasonic generators are set up separately. A safety thermostat (setting 15°C below the flash point) controls the adherence to a max. temperature and in case of excess temperature it switches the machine off. The cover included in the delivery avoids emissions from the tank during standstills. The machines can also be used in connection with aqueous cleaning methods. Options: • heating • extraction • cooling tube • ultrasonic frequencies 30 and/or 40 kHz • automation system • product carrier

Request for a quote

UNECOL ADHESIVE IDEAS, S.L.

Spain

Cleaning solvent for use in welded joints in polyethelyene (PE), polypropylene (PP), polybutene (PB) and Polyvinylidene fluoride (PVDF) pipes.

Request for a quote

PERO AG

Germany

In industrial parts cleaning, wet media are used in 70 to 90 % of all cleaning processes. Wet media include aqueous solutions – similar to detergents we use to wash our dishes or laundry – as well as nonaqueous solvents. For each cleaning task, project engineers must choose the best wet medium, taking into account ecological and economic considerations. Workpieces and parts are produced in finetuned production processes that often require the use of special consumables and process chemicals. Parts are generally made from specific materials, and their contamination after machining is determined by the processes they have undergone. When assessing the environmental impact of cleaning media, one sometimes comes to surprising conclusions. First of all, the energy input and use of resources must be assessed.

Request for a quote

PERO AG

Germany

After production of repair, the workpieces are lowered in a parts carrier into the immersion tank. A pump feeds cold cleaning agent containing solvents into the tank so that dirt is dissolved and removed by flooding. Persistent dirt can be removed manually with the flowthrough brush. The cleaning medium in the tank is constantly recirculated through a filter. Cleaning with sprayable cold cleaning agents containing hydrocarbons with a flash point > 60 °C Manual cleaning station Continuous filtration of cleaning medium Immersion tank suitable for wide range of workpieces Available as 1bath unit with loading of the unit via Manual loading

Request for a quote

NOVA KIMYA

Turkey

Usage Areas and Features: It is a very powerful degreaser. Does not contain flammable materials. It leaves absolutely no residue or sediments. It destroys the structure of the oil layers on the applied surface and absorbs it. The saturation rate is much higher than gasoline, diesel, thinner, etc., flammable and combustible materials. It does not have a corrosive effect on metals, does not rust and does not wear. It does not risk human health, does not harm nature, is biodegradable. Form of Use and Quantity: Applied by brush, dipping and wiping methods.

Request for a quote

FAC GB SRL

Italy

SOLVENT FOR CLEANING AND FOR DILUTE POLYCHLOROPRENE ADHESIVE S 700 is a solvent mixture to dilute polychloroprene adhesive type “CU”. Excellent also to clean brushes and machinery.

Request for a quote

GIDROLAST CO., LTD

United Kingdom

Gidrolast knows heavy trucks. We cut our teeth building hydraulic cylinders for heavy trucks all the way back in 1993. Hydraulic cylinders on trucks are subjected to all forms of contamination that would destroy a poorly designed cylinder. Dirt, grit, rain, salt, tar, chemicals, solvents and cleaning agents all combine to attack the cylinder and its seals. Despite all this, the cylinders are still expected to perform. Cylinder failure means downtime, employee overtime, loss of vehicle availability, less productivity and reduced profit. Gidrolast cylinders are built tough to meet these conditions. They can be found mounted on garbage trucks, dump trucks, belly dumpers, semi end dumpers, boom trucks, knuckle boom loaders, road pavers, concrete mixers, concrete pumps, mobile cranes, tilt beds and tow trucks. Applications include dump cylinders, aerial boom cylinders, compaction cylinders, outrigger cylinders, tilt cylinders, swing cylinders, plough lift cylinders, and more.

Request for a quoteResults for

Solvent cleaning - Import exportNumber of results

42 ProductsCountries

Company type

Category

- Cleaning machines, industrial (7)

- Solvents and thinners (4)

- Cleaning, industrial (3)

- Paint brushes and rollers (3)

- Disinfectants, non-medical (2)

- Silicones (2)

- Carboxylic and anhydric acids (1)

- Chemical catalysts (1)

- Chemicals - Basic Products & Derivatives (1)

- Cleaning - steel and metals (1)

- Cleaning and maintenance - equipment and supplies (1)

- Cleaning and maintenance products, household (1)

- Electric and electronic components - machines for manufacturing (1)

- Industrial cutting machine tools (1)

- Labelling machines (1)

- Laboratory equipment and instruments (1)

- Marble and natural stones (1)

- Platform hoists (1)

- Refrigerants (1)

- Screen printing on plastics and PVC (1)