- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- compressed air

Results for

Compressed air - Import export

OMEGA AIR

Slovenia

We are a producer of custom made pressure vessels according to PED or ASME standards. Pressure vessels are tanks, designed to store compressed air. Pressure vessels can also be designed for any other technical gas. Volume of pressure vessel depends on compressor capacity and on consumption of compressed air. Each of our pressure vessels is calculated, assembled, tested and guaranteed to conform standards and to withstand the process necessary for your application.

Request for a quote

OMEGA AIR

Slovenia

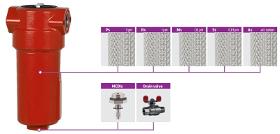

AAF compressed air filters are designed for the protection of the downstream compressed air system and equipment with lower airflows against defects and other failures. They ensure high efficient removal of solid particles, water, oil aerosols, hydrocarbons, odour and vapours from compressed air systems up to 16 bar. Required compressed air quality according to standard ISO 8571-1 can be achieved with 5 different grades of filter elements (P, R, M, S and A). Optional internal and external condensate drains should be used for efficient condensate draining from the filter housing.< /br> <b>Features</b> <ul> <li>A wider range of different models for different flow rates, including larger 2” and 3” sizes. </li> <li>Convenient design for assembly of several filters and for wall mounting</li> <li>AVELOCK antivibration element lock system<li> <li>Needle felt drainage layer instead of foam for improved thermal resistance<li> <li>X2-COAT internal anti-corrosion protection<li> </ul>

Request for a quote

OMEGA AIR

Slovenia

MAA-DRY membrane air dryers have been developed for high efficient removal of water vapours from compressed air. Super fine coalescing filter is required upstream.

Request for a quote

OMEGA AIR

Slovenia

COM-Dry dryers have been designed for continuous separation of water vapour from compressed air thus reducing dew point. Drying consist of two steps. Refrigerant dryer first eliminates large majority of water and reduces dew point down to PDP +3°C. Further reduction of dew point is carried out by adsorption dryer. Operation of dryer is more simple compared to conventional heat regenerated adsorption dryer while average compressed air losses present only up to 4,6 %.

Request for a quote

OMEGA AIR

Slovenia

Refrigerated compressed air dryer RDL utilizes a natural evolution of the RDP series. Drying is achieved on the principle of cooling which takes place inside highly efficient and ultra-compact 3 stage heat exchanger. This series is designed with focus on essential components. Its compact size, optimized layout and innovative solutions reduce manufacturing costs whilst maintaining the same levels of reliability, quality and attention to details. RDL refrigerated compressed air dryer is designed and manufactured with respect to the environment using recyclable materials.

Request for a quote

OMEGA AIR

Slovenia

Refrigeration dryers RDT have been designed to effectively separate water from the compressed air thus lower pressure dew point all the way down to +3 °C. The main difference between RDP and RDT series is that RDT has timer controlled drain instead of an automatic drain. Drying is achieved on the principle of cooling which takes place inside a highly efficient and ultra-compact 3 stage heat exchanger. In the first stage (air-air heat exchanger) hot and humid inlet air is being pre-cooled by the cold outgoing air. In the second stage (air-refrigerant heat exchanger) intensive water condensation takes place due to the cooling of the air. All condensed water is separated from the main compressed air stream in the third stage by the integrated demister. A proven and robust design enables efficient and reliable operation, fast installation and simple maintenance.

Request for a quote

OMEGA AIR

Slovenia

Refrigeration dryers have been designed to effectively separate water from the compressed air thus lower pressure dew point all the way down to +3°C. Drying is achieved on the principle of cooling which takes place inside highly efficient and ultra-compact 3 stage heat exchanger. In the first stage (air-air heat exchanger) hot and humid inlet air is being precooled by the cold outgoing air. In the second stage (air-refrigerant heat exchanger) intensive water condensation takes place due to cooling the air. All condensed water is separated from the main compressed air stream in the third stage by the integrated demister. A proven and robust design of refrigeration dryers enables efficient and reliable operation, fast installation and simple maintenance.

Request for a quote

OMEGA AIR

Slovenia

We are producing replacement filter elements according to ISO 8573-1. Alternative filters are tested by IUTA. Discover our range of replacement filters: ABAC, AGRE, AIRFILTER ENGINEERING, ALMIG, ALUP, ATLAS COPCO, ATS, BALMA, BEA, BEKO, BOGE, CECCATO, CHAUMECA, CHICAGO PNEUMATIC, CKD, COMPAIR, CTA, DELTECH, DOMNICK HUNTER, DONALDSON, EKOMAK, FIAC, FINITE, FUSHENG, HANKISON, HIROSS, HITACHI, INGERSOLL RAND, KAESER, KNOCKS, KOBELCO, KSI, MARK, MATTEI, MAUGUIERE, MIKROPOR, OMI, ORION, PNEUMATECH, PREVOST, PUSKA, SCHNEIDER, SMC, SPX NGF, SULLAIR, WALKER, WORTHINGTON CREYSSENSAC, ZANDER, ZONDER.

Request for a quote

OMEGA AIR

Slovenia

Desiccant adsorption compressed air dryer A-DRY has been designed to separate water moisture from compressed air thus reducing the dew point in the system. A-DRY is a range of products offering our customers a wide array of dried air solutions with volumetric flow rates ranging from 6 Nm³/h to 200 Nm³/h. An innovative new design of desiccant adsorption dryer A-DRY, developed with consideration of our customers, enables fast and reliable installation, use and servicing. Installation is simple with our ready to use controller while minimising the number of parts and motions required for assembly and disassembly makes servicing fast and reliable.

Request for a quote

OMEGA AIR

Slovenia

BF HP filters are designed for protection of the downstream compressed air system and equipment against defects and other failures in high pressure applications. Due to their robust welded carbon steel construction, are used for installation in heavy industrial applications with high air flows.They ensure high efficient removal of solid particles, water, oil aerosols, hydrocarbons, odour and vapours from compressed air systems up to 25 bar. Required compressed air quality according to standard ISO 8571-1 can be achieved with 6 different grades of filter elements (B, P, R, M, S and A). Optional external condensate drains should be used for efficient condensate draining from filter housing. Fluid group 1 on request.

Request for a quote

OMEGA AIR

Slovenia

AAFs filters are designed for applications in paint industry. Quantity of substances that could cause impairments in paint wetting applications or cause defects in paint work have been reduced to a minimum. To meet the required compressed air quality appropriate “paint compatible” filter element must be installed into filter housing.

Request for a quote

OMEGA AIR

Slovenia

Refrigeration high pressure compressed air dryers for compressed air RDHP makes the most of manufacturing and functional advantages of heat exchangers, designed for high pressure working conditions. Drying is achieved on the principle of cooling which takes place with highly efficient three stage air thermal management. Excellent performance with low pressure drop and constant pressure dew point is standard on this series. Robustness, simple and ergonomic component layout guarantees functionality and efficiency.

Request for a quote

OMEGA AIR

Slovenia

AAF HT series - Aluminium high temperature compressed air filters are designed for very high efficient removal of solid particles, water and oil aerosols, from compressed air systems in high-temperature applications. To be able to achieve the required compressed air quality, an appropriate filter element (BHT, N25HT, N5HT, XRHT, XMHT, XSHT) must be installed into the filter housing.

Request for a quote

OMEGA AIR

Slovenia

BF filters are designed for protection of the downstream compressed air system and equipment against defects and other failures. Due to their robust welded carbon steel construction, are used for installation in heavy industrial applications with high air flows.They ensure high efficient removal of solid particles, water, oil aerosols, hydrocarbons, odour and vapours from compressed air systems up to 16 bar. Required compressed air quality according to standard ISO 8571-1 can be achieved with 6 different grades of filter elements (B, P, R, M, S and A). Optional external condensate drains should be used for efficient condensate draining from filter housing. Fluid group 1 on request.

Request for a quote

OMEGA AIR

Slovenia

SPF stainless steel sterile filter housings are specially designed for applications in process industry, where the risk for corrosion of compressed air system components is very high. Required compressed air quality according to standard ISO 8571-1 can be achieved with appropriate filter element. SPF process filter housing can be used in variety of applications. For applications not listed please contact us or your local distributor. For oil removal, coalescing filter element must be installed and flow direction inside-out must be provided. General arrangement is filter head on the bottom and filter bowl on the top. Fluid group 1 on request.

Request for a quote

OMEGA AIR

Slovenia

SF stainless steel sterile filters are designed for high-efficient sterile filtration of compressed air, process air and technical gasses. SF sterile filters provide high-efficient removal of sub-micron particles down to 0,01μm including microorganisms (bacteria). Filter housing surface is polished down to grade Ra0,8. Required compressed air quality according to standard ISO 8571-1 can be achieved with appropriate filter element. All components meet the FDA requirements for contact with food in accordance with the Code of Federal Regulations (CFR), title 21. Fluid group 1 on request.

Request for a quote

OMEGA AIR

Slovenia

Water-cooled aftercooler ACW series has been designed to reduce compressed air temperature thus water vapour content in compressed air system. Hot compressed air/gas passes through the tubes. Cooling water passes around the tubes in counter flow. ACW aftercooler ensures the maximum performance and protection of all equipment, such refrigeration dryers, adsorption dryers and filters, positioned downstream of this unit.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

OMEGA AIR

Slovenia

Thermal mass flow sensor OS 401/OS421 is suitable for consumption measuring in different compressed air systems. The version with a display shows the volumetric flow and the total compressed air consumption. The keyboard enables setting of tube diameters and consumption counter. Various settings such as gas type, flow unit, reference standards, can also be set.

Request for a quoteResults for

Compressed air - Import exportNumber of results

19 ProductsCountries

Company type