- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- sintered ceramic

Results for

Sintered ceramic - Import export

XIAMEN NINESUN IMP. & EXP. CO., LTD

China

Features: Made of ground sintered SmCo magnet Powder is mixed with resin and molded like NdFeB bonded magnet No need to be coated because it is difficult to erode and oxidize High-BH (maximum) High-Br and Hc with high-operating temperature, low-temperature coefficient, counter-demagnetization, decay resistance Main products cover SmCo5 and Sm2Co17 magnets, samarium cobalt powder, various assemblies and more OEM orders are welcomed Applications: Widely used in motors, watches, transducers, instruments, positional detectors, generators, radars and more High quality, competitive price, best service

Request for a quote

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

Silicon nitride (Si3N4) is a high-melting-point material with high fracture toughness and excellent thermal shock resistance, It is considered to be one of the few monolithic ceramic materials that can withstand severe thermal shock and thermal gradient generated by hydrogen and oxygen rocket engines.

Request for a quote

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

Silicon Nitride (Si3N4) is 60% lighter than steel but strong enough to survive some of the most demanding applications in a variety of industries. This lightweight, the high-strength ceramic material is used as an alternative to stainless steel, super alloys, tungsten carbides, and first-generation ceramics such as Al2O3 and ZrO2. It offers excellent thermal shock resistance and high fracture toughness, compatibility with nonferrous metal melts, and improved structural reliability compared to other ceramic materials. When extreme conditions like these push equipment to its limits, Silicon Nitride (Si3N4) industrial ceramics deliver high performance where other materials fail. Typically, Heavy-duty diesel engines. Jet engine igniters. Oil wells thousands of feet underground. Applications for silicon nitride include: Foundries Electronics Oil & Gas Automotive Aerospace

Request for a quote

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

Silicon Nitride Ceramic Bar: Silicon Nitride (Si3N4) is 60% lighter than steel but strong enough to survive some of the most demanding applications in a variety of industries. This lightweight, high-strength ceramic material is used as an alternative to stainless steel, super alloys, tungsten carbides and first-generation ceramics such as Al2O3 and ZrO2. It offers excellent thermal shock resistance and high fracture toughness, compatibility with nonferrous metal melts, and improved structural reliability compared to other ceramic materials. Silicon Nitride (Si3N4) Characteristics: >Good thermal shock resistance >Creep resistance >Low density >High fracture toughness >High hardness and wear resistance >Electrical resistivity

Request for a quote

XIAMEN INNOVACERA ADVANCED MATERIALS CO., LTD

China

The boron nitride setter plate is made of high purity 99.7% boron nitride ceramics, has a high operating temperature in an inert gas (2100℃) and vacuum (1900℃) environment. It has excellent thermal shock resistance which can be used for applications having sudden temperature changes. It will not react or wet with a wide range of molten metals and glass. It is also a good electrical insulator. Boron nitride ceramic setter plate for sintering AlN Si3n4 Substrates. The maximum size to produce is 480mm x 480mm, plain holes, thread holes, grooves or shoulders could be machined on the plate. In this field, we can offer precision machined components. Features of 99.7% Boron Nitride: * High thermal conductivity * Low thermal expansion * Good thermal shock resistance * High electrical resistance * Low dielectric constant and loss tangent * Microwave transparency * Non-toxic * Easily machined — non-abrasive and lubricious * Chemically inert * Not wet by most molten metals

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

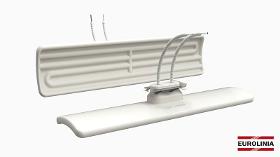

EUROLINIA

Belarus

Made of high-alumina chamotte containing 65 to 72% Aluminum oxide. Sintered high-alumina ceramics' high thermal conductivity allows obtaining the most uniform temperature across the radiation surface, providing uniform and high-quality radiant heating. These elements are often used in thermoforming machines, drying chambers, infrared tunnels and panels, heating and drying equipment, and various commercial heaters. Estimated service life at least 8,000 - 10,000 hours of non-stop operation. Maximun temperature 750°C. Comply with all international standards and are interchangeable with all known brands (FTE/FSR/FSF/HTC/HTE).

Request for a quote

EUROLINIA

Belarus

Made of high-alumina chamotte containing 65 to 72% Aluminum oxide. Sintered high-alumina ceramics' high thermal conductivity allows obtaining the most uniform temperature across the radiation surface, providing uniform and high-quality radiant heating. These elements are often used in thermoforming machines, drying chambers, infrared tunnels and panels, heating and drying equipment, and various commercial heaters. Estimated service life at least 8,000 - 10,000 hours of non-stop operation. Maximun temperature 750°C. Comply with all international standards and are interchangeable with all known brands (FTE/FSR/FSF/HTC/HTE).

Request for a quote

EUROLINIA

Belarus

Made of high-alumina chamotte containing 65 to 72% Aluminum oxide. Sintered high-alumina ceramics' high thermal conductivity allows obtaining the most uniform temperature across the radiation surface, providing uniform and high-quality radiant heating. These elements are often used in thermoforming machines, drying chambers, infrared tunnels and panels, heating and drying equipment, and various commercial heaters. Estimated service life at least 8,000 - 10,000 hours of non-stop operation. Maximun temperature 750°C. Comply with all international standards and are interchangeable with all known brands (FTE/FSR/FSF/HTC/HTE).

Request for a quote

EUROLINIA

Belarus

Made of high-alumina chamotte containing 65 to 72% Aluminum oxide. Sintered high-alumina ceramics' high thermal conductivity allows obtaining the most uniform temperature across the radiation surface, providing uniform and high-quality radiant heating. These elements are often used in thermoforming machines, drying chambers, infrared tunnels and panels, heating and drying equipment, and various commercial heaters. Estimated service life at least 8,000 - 10,000 hours of non-stop operation. Maximun temperature 750°C. Comply with all international standards and are interchangeable with all known brands (FTE/FSR/FSF/HTC/HTE).

Request for a quote

EUROLINIA

Belarus

Made of high-alumina chamotte containing 65 to 72% Aluminum oxide. Sintered high-alumina ceramics' high thermal conductivity allows obtaining the most uniform temperature across the radiation surface, providing uniform and high-quality radiant heating. These elements are often used in thermoforming machines, drying chambers, infrared tunnels and panels, heating and drying equipment, and various commercial heaters. Estimated service life at least 8,000 - 10,000 hours of non-stop operation. Maximun temperature 750°C. Comply with all international standards and are interchangeable with all known brands (FTE/FSR/FSF/HTC/HTE).

Request for a quote

PVA INDUSTRIAL VACUUM SYSTEMS GMBH

Germany

OV heat treatment furnaces are high performance most efficient furnaces with a wide working-temperature and application range. Due to the compatibility with all kind of process gases and the fully automatic process runs they are especially suitable for the economic application in industrial productions for example to produce hard metals or the cleaning and purification of graphite. Applications: • operating temperatures up to 1.100 °C: heat treatment, brazing, reduction, degassing and debinding • operating temperatures up to 1.350 °C: heat treatment, brazing, degassing, debinding and sintering • operating temperatures up to 1.600 °C: debinding and sintering of hard metals • operating temperatures up to 1.800 °C: sintering of non-oxydic ceramics • operating temperatures up to 2.000°C: CVD- and pyrolytic processes, degassing, cleaning, sintering • operating temperatures up to 2.400 °C: CVD-processes, degassing, cleaning • operating temperatures above 2.

Request for a quote

NIPPON KORNMEYER CARBON GROUP GMBH

Germany

NKCG offers a complete portfolio of carbon-based products for vacuum sintering process of hard metals and ceramics.

Request for a quoteResults for

Sintered ceramic - Import exportNumber of results

13 ProductsCountries

Company type