- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- silo systems

Results for

Silo systems - Import export

IFA TECHNOLOGY GMBH

Germany

As a specialist company according to the German Water Resources Act (WHG), IFA Technology offers expert planning and consulting for the storage of liquids or bulk materials. In the area of so-called LAU plants and systems (plants and systems for storage, filling and handling), our product range includes tank farms and silo systems which, depending on the requirements, consist of mild steel, stainless steel, plastic and GRP tanks. To meet the legal requirements, LAU plants and systems from IFA Technology can be supplied specially coated (HALAR, Teflon, etc.), varnished or painted.

Request for a quote

ELKON GMBH

Germany

ELKON Bag Cement Feeding System consists of cement feeding bunker, intermediary cement feeding screw and control panel. The operator puts the cement bag into the cement feeding hopper and tears it by means of the cutters on the hopper. Then the cement is transferred to the cement silo by cement screw. This system can be used to feed 1 unit of cement silos as well as 2 units of silo by using distribution valve.

Request for a quote

ROBINSON CO.

Turkey

Silo Discharger are an indispensable part of industrial enterprises. They are usually used for fast and efficient unloading of materials accumulated in silos. These machines are used in many sectors, for example, cement, flour, semolina, sugar, bran and many more are important for the storage and use of industrial materials. Application Fields ◾ At food processing industry ◾ Flour and semolina mills ◾ Macaroni factories ◾ Feed mills ◾ At other similar industrial plants

Request for a quote

PARSMEGA MAKINA

Turkey

Funnel-shaped silos have an angle of 45º or 60º, which allows the grain to flow with its own fluidity. However, 45º conical bottoms are used for grains, and 60º conical bottoms are used for feeding purposes, moist grains or low-fluidity materials. Conical bottom silos are produced from 5 tons to 1,000 tons. Generally, they are operated in a continuous discharge state. Low energy consumption and operating costs during the unloading process are one of the reasons why these silos are preferred. Special steel structures, chassis and platforms have been developed for conical bottom silos. These steel structures are placed at the bottom of the silo to add height to the silo unit. These combined systems are designed for easy and healthy loading of wagons.

Request for a quote

PARSMEGA MAKINA

Turkey

Valves are generally used to control the product flow under flat-bottom silos with tunnel systems, chain conveyors and conical-bottom silos. It has a wide application area with its galvanized steel structure.

Request for a quote

PARSMEGA MAKINA

Turkey

Ladders and platforms are produced completely modularly with galvanized sheets. Holes; It is drilled with the latest technology punching machines to facilitate screwing operations. Exterior and interior stairs; It can be joined to existing holes using fasteners. Standard silo external ladder safety system allows people to reach the roof safely. The rest platform is placed under the roof entrance cover for easy access to the roof or for your safety when entering the silo.

Request for a quote

DOHOGNE SYSTEM SA

Belgium

Product = Pellets Extraction System = by gravity > belt conveyor under silo bottom 1 x 200m³ silo, Ø5m56 Product = Pellets Extraction System = by gravity > lorry (Belgium)

Request for a quote

DOHOGNE SYSTEM SA

Belgium

Modular, extendable silos, adapted to industrial storage capacities for all bulk products and allowing for complete emptying and refilling with another product without requiring any intermediate cleaning. DOHOGNE SYSTEM silos are constructed from curved panels with external bolts, are self-cleaning, can be dismantled and are interchangeable. Their thickness varies from 2 to 4 mm, and standard dimensions are 940 x 1940 mm. Robust, sealed silos resulting from over 50 years’ experience, complying with European standard EN 1991-4 and with all specific static and dynamic storage criteria. Prefabricated silos, cheap to transport, meaning that: -It is possible to install the silos within an existing complex since they arrive on site in component parts, without needing extensive access as required by a classic, welded-construction silo; -Rapid assembly techniques do not require heavy infrastructure on site.

Request for a quote

DOHOGNE SYSTEM SA

Belgium

Modular, extendable silos, adapted to industrial storage capacities for all bulk products and allowing for complete emptying and refilling with another product without requiring any intermediate cleaning. DOHOGNE SYSTEM silos are constructed from curved panels with external bolts, are self-cleaning, can be dismantled and are interchangeable. Their thickness varies from 2 to 4 mm, and standard dimensions are 940 x 1940 mm. Robust, sealed silos resulting from over 50 years’ experience, complying with European standard EN 1991-4 and with all specific static and dynamic storage criteria. Prefabricated silos, cheap to transport, meaning that: -It is possible to install the silos within an existing complex since they arrive on site in component parts, without needing extensive access as required by a classic, welded-construction silo; -Rapid assembly techniques do not require heavy infrastructure on site.

Request for a quote

DOHOGNE SYSTEM SA

Belgium

Modular, extendable silos, adapted to industrial storage capacities for all bulk products and allowing for complete emptying and refilling with another product without requiring any intermediate cleaning. DOHOGNE SYSTEM silos are constructed from curved panels with external bolts, are self-cleaning, can be dismantled and are interchangeable. Their thickness varies from 2 to 4 mm, and standard dimensions are 940 x 1940 mm. Robust, sealed silos resulting from over 50 years’ experience, complying with European standard EN 1991-4 and with all specific static and dynamic storage criteria. Prefabricated silos, cheap to transport, meaning that: -It is possible to install the silos within an existing complex since they arrive on site in component parts, without needing extensive access as required by a classic, welded-construction silo; -Rapid assembly techniques do not require heavy infrastructure on site.

Request for a quote

DOHOGNE SYSTEM SA

Belgium

Modular, extendable silos, adapted to industrial storage capacities for all bulk products and allowing for complete emptying and refilling with another product without requiring any intermediate cleaning. DOHOGNE SYSTEM silos are constructed from curved panels with external bolts, are self-cleaning, can be dismantled and are interchangeable. Their thickness varies from 2 to 4 mm, and standard dimensions are 940 x 1940 mm. Robust, sealed silos resulting from over 50 years’ experience, complying with European standard EN 1991-4 and with all specific static and dynamic storage criteria. Prefabricated silos, cheap to transport, meaning that: -It is possible to install the silos within an existing complex since they arrive on site in component parts, without needing extensive access as required by a classic, welded-construction silo; -Rapid assembly techniques do not require heavy infrastructure on site.

Request for a quote

DOHOGNE SYSTEM SA

Belgium

Modular, extendable silos, adapted to industrial storage capacities for all bulk products and allowing for complete emptying and refilling with another product without requiring any intermediate cleaning. DOHOGNE SYSTEM silos are constructed from curved panels with external bolts, are self-cleaning, can be dismantled and are interchangeable. Their thickness varies from 2 to 4 mm, and standard dimensions are 940 x 1940 mm. Robust, sealed silos resulting from over 50 years’ experience, complying with European standard EN 1991-4 and with all specific static and dynamic storage criteria. Prefabricated silos, cheap to transport, meaning that: -It is possible to install the silos within an existing complex since they arrive on site in component parts, without needing extensive access as required by a classic, welded-construction silo; -Rapid assembly techniques do not require heavy infrastructure on site.

Request for a quote

DOHOGNE SYSTEM SA

Belgium

Photo : Assembly roof Modular, extendable silos, adapted to industrial storage capacities for all bulk products and allowing for complete emptying and refilling with another product without requiring any intermediate cleaning. DOHOGNE SYSTEM silos are constructed from curved panels with external bolts, are self-cleaning, can be dismantled and are interchangeable. Their thickness varies from 2 to 4 mm, and standard dimensions are 940 x 1940 mm. Robust, sealed silos resulting from over 50 years experience, complying with European standard EN 1991-4 and with all specific static and dynamic storage criteria. Prefabricated silos, cheap to transport, meaning that: -It is possible to install the silos within an existing complex since they arrive on site in component parts, without needing extensive access as required by a classic, welded-construction silo; -Rapid assembly techniques do not require heavy infrastructure on site.

Request for a quote

DOHOGNE SYSTEM SA

Belgium

Modular, extendable silos, adapted to industrial storage capacities for all bulk products and allowing for complete emptying and refilling with another product without requiring any intermediate cleaning. DOHOGNE SYSTEM silos are constructed from curved panels with external bolts, are self-cleaning, can be dismantled and are interchangeable. Their thickness varies from 2 to 4 mm, and standard dimensions are 940 x 1940 mm. Robust, sealed silos resulting from over 50 years’ experience, complying with European standard EN 1991-4 and with all specific static and dynamic storage criteria. Prefabricated silos, cheap to transport, meaning that: -It is possible to install the silos within an existing complex since they arrive on site in component parts, without needing extensive access as required by a classic, welded-construction silo; -Rapid assembly techniques do not require heavy infrastructure on site.

Request for a quote

DOHOGNE SYSTEM SA

Belgium

Modular, extendable silos, adapted to industrial storage capacities for all bulk products and allowing for complete emptying and refilling with another product without requiring any intermediate cleaning. DOHOGNE SYSTEM silos are constructed from curved panels with external bolts, are self-cleaning, can be dismantled and are interchangeable. Their thickness varies from 2 to 4 mm, and standard dimensions are 940 x 1940 mm. Robust, sealed silos resulting from over 50 years’ experience, complying with European standard EN 1991-4 and with all specific static and dynamic storage criteria. Prefabricated silos, cheap to transport, meaning that: -It is possible to install the silos within an existing complex since they arrive on site in component parts, without needing extensive access as required by a classic, welded-construction silo; -Rapid assembly techniques do not require heavy infrastructure on site.

Request for a quote

DOHOGNE SYSTEM SA

Belgium

Ø12m35 Total height 10 m Product = dry woodchips, protection against explosions Extraction System = Planetary screw extractor ( The Netherlands ) Modular, extendable silos, adapted to industrial storage capacities for all bulk products and allowing for complete emptying and refilling with another product without requiring any intermediate cleaning. DOHOGNE SYSTEM silos are constructed from curved panels with external bolts, are self-cleaning, can be dismantled and are interchangeable. Their thickness varies from 2 to 4 mm, and standard dimensions are 940 x 1940 mm. Robust, sealed silos resulting from over 50 years’ experience, complying with European standard EN 1991-4 and with all specific static and dynamic storage criteria.

Request for a quote

DOHOGNE SYSTEM SA

Belgium

Photo : The inside of silos DOHOGNE SYSTEM have a completely smooth wall what allows the complete emptying for all bulk products. Modular, extendable silos, adapted to industrial storage capacities for all bulk products and allowing for complete emptying and refilling with another product without requiring any intermediate cleaning. DOHOGNE SYSTEM silos are constructed from curved panels with external bolts, are self-cleaning, can be dismantled and are interchangeable. Their thickness varies from 2 to 4 mm, and standard dimensions are 940 x 1940 mm. Robust, sealed silos resulting from over 50 years’ experience, complying with European standard EN 1991-4 and with all specific static and dynamic storage criteria.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

DOHOGNE SYSTEM SA

Belgium

Modular, extendable silos, adapted to industrial storage capacities for all bulk products and allowing for complete emptying and refilling with another product without requiring any intermediate cleaning. DOHOGNE SYSTEM silos are constructed from curved panels with external bolts, are self-cleaning, can be dismantled and are interchangeable. Their thickness varies from 2 to 4 mm, and standard dimensions are 940 x 1940 mm. Robust, sealed silos resulting from over 50 years’ experience, complying with European standard EN 1991-4 and with all specific static and dynamic storage criteria. Prefabricated silos, cheap to transport, meaning that: -It is possible to install the silos within an existing complex since they arrive on site in component parts, without needing extensive access as required by a classic, welded-construction silo; -Rapid assembly techniques do not require heavy infrastructure on site.

Request for a quote

DOHOGNE SYSTEM SA

Belgium

Modular, extendable silos, adapted to industrial storage capacities for all bulk products and allowing for complete emptying and refilling with another product without requiring any intermediate cleaning. DOHOGNE SYSTEM silos are constructed from curved panels with external bolts, are self-cleaning, can be dismantled and are interchangeable. Their thickness varies from 2 to 4 mm, and standard dimensions are 940 x 1940 mm. Robust, sealed silos resulting from over 50 years’ experience, complying with European standard EN 1991-4 and with all specific static and dynamic storage criteria. Prefabricated silos, cheap to transport, meaning that: -It is possible to install the silos within an existing complex since they arrive on site in component parts, without needing extensive access as required by a classic, welded-construction silo; -Rapid assembly techniques do not require heavy infrastructure on site.

Request for a quote

DOHOGNE SYSTEM SA

Belgium

Modular, extendable silos, adapted to industrial storage capacities for all bulk products and allowing for complete emptying and refilling with another product without requiring any intermediate cleaning. DOHOGNE SYSTEM silos are constructed from curved panels with external bolts, are self-cleaning, can be dismantled and are interchangeable. Their thickness varies from 2 to 4 mm, and standard dimensions are 940 x 1940 mm. Robust, sealed silos resulting from over 50 years’ experience, complying with European standard EN 1991-4 and with all specific static and dynamic storage criteria. Prefabricated silos, cheap to transport, meaning that: -It is possible to install the silos within an existing complex since they arrive on site in component parts, without needing extensive access as required by a classic, welded-construction silo; -Rapid assembly techniques do not require heavy infrastructure on site.

Request for a quote

DOHOGNE SYSTEM SA

Belgium

Product = dry woodchips, protection against explosions Extraction System = Planetary screw extractor + Sand color paint (Portugal) Modular, extendable silos, adapted to industrial storage capacities for all bulk products and allowing for complete emptying and refilling with another product without requiring any intermediate cleaning. DOHOGNE SYSTEM silos are constructed from curved panels with external bolts, are self-cleaning, can be dismantled and are interchangeable. Their thickness varies from 2 to 4 mm, and standard dimensions are 940 x 1940 mm. Robust, sealed silos resulting from over 50 years’ experience, complying with European standard EN 1991-4 and with all specific static and dynamic storage criteria.

Request for a quote

ELKON GMBH

Germany

The cement stored in the cement silos can be quickly discharged to the cement trailers (bulk carrier) by means of ELKON telescopic cement loading bellow. This system has a special structure with support legs allowing the bulk carrier parking under the discharge point and is equipped with a suitable bellow for feeding the material. ELKON telescopic cement loading bellow is equipped with level indicator to stop loading and lift up the bellow when it is in contact with the cement (material filling process is finalized). The bellow is also equipped with fan filter system to prevent powder during the material filling process. The system includes a control panel as well.

Request for a quote

ELKON GMBH

Germany

Cement material supplied with big bags or bags can be transferred into cement silos by means of ELKON Big Bag/Bag Pneumatic Cement Feeding System. ELKON Big Bag/Bag Pneumatic Cement Feeding System consists of cement feeding hopper, intermediary feeding screw, pressure tank, compressor, loading crane and control panel. This feeding system, which has a capacity of 15 tons/hour, is equipped with 2 tons crane to lift the big bags and dispatch into the feeding hopper. The complete set of ELKON Big Bag/Bag Pneumatic Cement Feeding System fits into 1 unit 40’OT container and thus it can be easily transported to overseas countries.

Request for a quote

ELKON GMBH

Germany

In some countries, cement is widely delivered by railway. The cement carried in wagons can be transferred to the cement silos with special pneumatic cement feeding system developed by ELKON. ELKON Cement Delivery System from Railway consists of wagon feeding hopper, intermediary feeding screw, material holding tank, pressure tank, compressor and control panel. The system which has a cement feeding capacity of 50 tons / hour can also be used to feed a large number of cement silos.

Request for a quote

ELKON GMBH

Germany

ELKON horizontal cement silos are preferred in cases where the silo location is planned to be changed frequently or in projects with height restrictions. In horizontal cement silos designed by experienced engineers of ELKON, materials with similar properties such as cement, lime, fly ash, sand etc. can be stored. Horizontal cement silos are used by placing them on the ground without the need for any foundation and ground connection, and when they need to be transported, they can be loaded and transported on the truck without the need for a crane in a very short time by means of adjustable telescopic legs. 40 and 70 ton capacity models are used both for storage and dosing. These silos with heavy-duty structures have been designed for both sea and land transportation. With axle and tyres which are presented optionally, the silo can be easily towed to the desired location on its own structure.

Request for a quote

ELKON GMBH

Germany

ELKON Cement silos are precisely manufactured by the fully automatic welding robots in production molds in ELKON-3 factory which is dedicated only for the production of cement silos. For easy and efficient transportation, ELKON provides a wide range of bolted type cement silos with the capacity of 50, 75, 100, 150, 300 and 500 tons.

Request for a quote

LIPP GMBH BEHÄLTER UND SYSTEMLÖSUNGEN

Germany

WIDE RANGE OF TANK ACCESSORIES FOR TECHNICAL EQUIPMENT Whether grain silos, biogas systems or liquid manure containers, Lipp places the greatest importance on quality, safety, a long service life and cost efficiency over its entire product portfolio – including accessories. The whole is more than the sum of its parts. That is especially true for Lipp container solutions and systems as special attention is paid to all parts – including tank accessories – to ensure quality, safety, longevity and cost efficiency. A broad range of technical tank accessories is available for all containers. Some are produced in house and some are purchased via partners or carefully selected suppliers with whom Lipp has established long term relationships based on trust. ACCESSORIES Container bottoms Container insulation Pumping and stirring technology Overflow gutters Container heating Steps, platforms and operating bridges Overpressure and underpressure protection devices Pipeline construction

Request for a quote

LIPP GMBH BEHÄLTER UND SYSTEMLÖSUNGEN

Germany

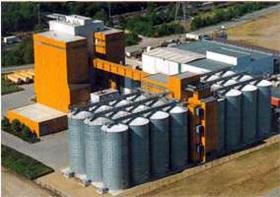

GUARANTEED OPTIMUM STORAGE FOR A WIDE VARIETY OF MATERIALS The storage of bulk materials needs to be not only cost effective but also safe, and systems should be easy to integrate in production processes. LIPP Double Seam technology and welded LIPP tanks have proven to be particularly suitable for bulk storage applications in industry and agriculture. LIPP silos provide a high level of stability and total leak tightness and protect bulk materials from moisture. The smooth internal walls of the silos are a benefit that pays dividends when storing special media. All kinds of bulk materials Grain Soya Silage fodder Woodchips Pellets Clinker brick Cement SILOS FOR STORING GRAIN AND OTHER FOODSTUFFS Grain, soya and other foodstuffs are precious commodities and a major asset in agriculture and they need to be stored particularly carefully. With the tried and tested Lipp Double Seam System, Lipp silos offer major benefits in terms of design and leak tightness.

Request for a quote

IFA TECHNOLOGY GMBH

Germany

IFA Technology offers the complete range of conveying systems, storage systems and handling systems in mechanical engineering. Our plants and systems can be integrated into your own conveyor line or designed as completely automated systems. External plant components can also be integrated into our superordinate control system. Our plants and systems are mainly used for bagging or bottling or batch loading systems. Application of conveying, storage and handling systems: Dosing and application of liquids in the plant process Dosing and mixing of powders, fibres and liquids Bagging and bottling systems integrated into a production line Silo systems and tank systems with conveying paths and mixing systems Pipe shell plants

Request for a quoteResults for

Silo systems - Import exportNumber of results

55 ProductsCompany type

Category

- Silos, metal (26)

- Concrete mixers (6)

- Goods handling systems, continuous (4)

- Oils, cooking - machinery and equipment (3)

- Tanks, metal (3)

- Silos, farm (2)

- Weight and mass - measurement and regulation instruments (2)

- Agglomeration and emulsification machines for the food processing industry (1)

- Agricultural Production (1)

- Agriculture - Machines & Equipment (1)

- Air-conditioning systems, vehicles (1)

- Bag filling machinery and equipment (1)

- Cereals and grains (1)

- Clutches (1)

- Concrete preparing - machinery and equipment (1)

- Measurement and regulation equipment and instruments - output and flow (1)

- Silos, plastic (1)