- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- welding consumables

Results for

Welding consumables - Import export

EUROPONTEX IMPORTAÇÂO & EXPORTAÇÂO

Portugal

Stick Electrode, fluxes, solid wires, SAW wires, flux-Cored wires, welding Processes and Machines.

Request for a quote

MAGAGER, UNIPESSOAL, LDA

Portugal

Silicone-free water-based anti-splash Spraymig H2O, based on highly efficient water-soluble substances. It prevents splashes from sticking to robot nozzles, tips and workpieces and considerably extends the life of the nozzles. Allows quick changing and cleaning of nozzles. It is possible to paint, galvanize, varnish parts. A preliminary test is recommended. Very low consumption for high effectiveness. Water-based and odorless. No influence on porosity and cold cracking. No influence of the diffusible hydrogen content in the weld metal. Soluble and silicone-free. Biodegradable. Allows you to lacquer parts. Physical and chemical properties: Appearance: clear colorless liquid. Density at 20 °C: 1.00. Pure pH: 7. Propellant gas: dimethyl ether. Base: water-based emulsion of organic substances

Request for a quote

MAGAGER, UNIPESSOAL, LDA

Portugal

Silicone-free water-based anti-splash Spraymig H2O, based on highly efficient water-soluble substances. It prevents splashes from sticking to robot nozzles, tips and workpieces and considerably extends the life of the nozzles. Allows quick changing and cleaning of nozzles. It is possible to paint, galvanize, varnish parts. A preliminary test is recommended. Very low consumption for high effectiveness. Water-based and odorless. No influence on porosity and cold cracking. No influence of the diffusible hydrogen content in the weld metal. Soluble and silicone-free. Biodegradable. Allows you to lacquer parts. Physical and chemical properties: Appearance: clear colorless liquid. Density at 20 °C: 1.00. Pure pH: 7. Volume: Spray: 400 ml (liquid), 520 ml (nominal) Propellant gas: dimethyl ether. Base: aqueous emulsion of organic substances.

Request for a quote

MAGAGER, UNIPESSOAL, LDA

Portugal

Protection of welded joints. Allows welded parts to be lacquered. GALVASPRAY sprays a protective zinc finish. High resistance to oxidation and corrosion (more than 80 hours in salt fog) Quick drying (about 5 minutes) and no drips. Volume: 400 ml (liquid) - 520 ml (nominal). Propellant gas: propane/butane. Base: zinc powder in vegetable resin. Instructions for use: Clean and degrease the area to be treated. Shake the can before using for at least 1 minute. Spray 25 cm away from the piece in short, even passes.

Request for a quote

MAGAGER, UNIPESSOAL, LDA

Portugal

aluminum welding wire MIG/MAG (GMAW) Welding | ED701763 General purpose filler alloy for 5XXX and 6XXX series alloys The most widely used soldering alloy High strength filler metal

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

MAGAGER, UNIPESSOAL, LDA

Portugal

Copper clad solid wire used in general purpose, single or multipass soldering for use with CO2 shielding gas or Air/CO2 mixture. MIG/MAG welding (GMAW)

Request for a quote

MAGAGER, UNIPESSOAL, LDA

Portugal

For welding with self-shielded cored wire (FCAW-S)

Request for a quote

MAGAGER, UNIPESSOAL, LDA

Portugal

Smooth and stable arc. Well suited for positional welding (particularly vertical and overhead). Good slag removal even in narrow spaces. Stick (SMAW)

Request for a quote

MARXAM PROJECT

Poland

The steel welding process is a key technology for the production of metal structures. We weld stainless steel structural elements, as well as entire structures made of structural steel, stainless steel, aluminum and its alloys. The main welding types used by us are: a) arc welding with a consumable electrode in the shield of inert gasses (MIG welding) and active gasses (MAG welding); b) arc welding with a non-consumable electrode in protective gasses (TIG welding); c) 3D laser welding. The specificity of the welding services and its belonging to special processes mean that it is carried out in our plant only by qualified employees who undergo regular training to improve their qualifications. The uncompromising approach allowed us to weld in industries with increased requirements: automotive, aviation and railway. In the metal welding process, we can also use a welding robot, which allows us to achieve high repeatability and welding quality for small and large production series.

Request for a quote

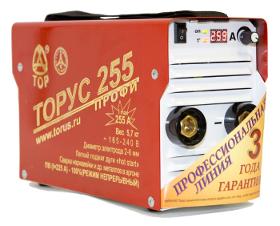

COMPANY TOR

Russia

TORUS-255 has the widest possible range of arc welding currents (from 20 to 255 A), which makes it possible to use it both for welding very thin metals, including in the TIG mode (welding with non-consumable electrode), and for continuous welding of large metal structures using an electrode up to 6 mm in diameter. The operating margin in the ТОРУС-255 device is such that it can be effectively used not only for the MMA and TIG modes, but also in the surfacing and cutting modes. At the same time, the weight of the device itself is traditionally not big – only 5.7 kg. Like all devices of the ТОРУС line, ТОРУС-255 has increased reliability with all its maximum parameters. A 3-year manufacturer’s warranty is a guarantee of its high performance in the most severe operating conditions.

Request for a quote

COMPANY TOR

Russia

The VIKING TIG 315 AC / DC PRO argon-arc welding machine is a one-piece structure, designed for power supply from a three-phase 380 V network and produces 315 A at a load of 60%. Special software functions significantly increase the performance factor of the device: HOT-START, ARC-FORCE, ANTI-STICK functions. Specifications: Voltage: V380 Max power: kW5.5 Max current: A315 Operating mode: DC/AC Product class: Professional Burner operating mode: 2-stroke / 4-stroke Pulse mode: yes Availability of the button for saving the selected parameters “MEMORY”, allows you to program 10 parameters for each welding mode (AC/DC). PULSE welding mode is a pulsed consumable-electrode welding (Possibility to use both direct current (DC) and alternative (AC). Waveform selection function (available in AC mode). Dot welding mode 2T and 4T. Adjusting of smooth drop of the terminating current. Adjustable inductance.

Request for a quote

W&K METALLVERARBEITUNG GMBH

Germany

• TIG welding: The letters TIG stand for tungsten inert gas welding and generally belong to the inert gas welding process. In this welding process, an arc burns between a tungsten electrode (non-consumable) and the workpiece. The electrode, the arc and the molten bath are protected from the atmosphere by an inert gas. • MIG / MAG welding: The letters MIG stand for metal inert gas, the letters MAG for metal active gas. This welding process is also part of the group of metal inert gas welding processes. In this welding process, a consumable wire electrode is fed continuously. The arc burns between the supplied wire and the workpiece. Throughout the welding process, the arc and the weld pool are protected by either an active gas (MAG process) or an inert gas (MIG process). This welding process can be used for a variety of materials and is also available for a large number of welding consumables.

Request for a quoteResults for

Welding consumables - Import exportNumber of results

15 ProductsCountries

Company type