- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- tool manufacturer

Results for

Tool manufacturer - Import export

NAIDEKA, UAB

Lithuania

NAIDEKA, UAB is metal processing company, manufacturing stamps, dies, punches, tooling.

Request for a quote

BVS ELECTRONICS GMBH

Germany

HELLER uniPro 90 Machine tools manufactured by HELLER are used around the world in the machining sector. Many of the older processing centres are using the "uniPro 90" controller for which we offer completely reconditioning repairs across the entire product range. In addition we are selling new, replacement and exchange parts. We are also able to test these HELLER controllers on our internally developed test stand and guarantee full functionality following repair. By using original components for every repair, we can also offer you an 24month warranty* on the complete assembly. The product portfolio for the HELLER uniPro 90 product range currently consists of inputs and outputs, plugin cards from the ACPU90 range, control panels, system cards and power modules.

Request for a quote

HODA, UAB

Lithuania

HODA, UAB has reliable mold manufacturing partners in Europe and Asia.

Request for a quote

HODA, UAB

Lithuania

HODA, UAB has reliable mold manufacturing partners in Europe and Asia. Also our company has all needed equipment to manufacture plastic moulds and plastic mould tools.

Request for a quote

HODA, UAB

Lithuania

HODA, UAB produces plastic products for the electrical industry. Our company provides that services: mould tool manufacturing, plastic injection moulding, insert overmoulding, DC (dual- component) injection moulding, gas assisted injection moulding, thermoset moulding, plastic blow moulding, decoration, tampo printing, screen printing, wet painting, assembly and packaging, local and international delivery.

Request for a quote

HODA, UAB

Lithuania

HODA, UAB offers all plastic molding services including product tooling, molding and manufacturing. We serve a number of challenging markets including automotive, appliances, electrical, medical, business equipment, telecommunications and others. Our company is proud ourselves in providing exactly what the customer needs and developing long-term partnerships.

Request for a quote

HODA, UAB

Lithuania

At the moment HODA, UAB operates 54 injection moulding machines, which gives us flexibility to produce different size and purpose plastic parts from a fraction of gram up to six kilograms of mass. HODA, UAB services: Mould tool manufacturing, Plastic injection moulding, Insert overmoulding, DC (dual- component) injection moulding, Gas assisted injection moulding, Thermoset moulding, Plastic blow moulding, Decoration, Tampo printing, Screen printing, Wet painting, Assembly and packaging, Local and international delivery.

Request for a quote

HEMOGUM

Serbia

we design. manufacture and test new products from the previous*/ determined requirements, from me design phase of virtual models using the most advanced 3D software, through examnng with the end element method, up to the prototype and tools manufacture for mass production. Ccftsidenng our big e»penence in 3D software application, m are able to maximally shorten the devetopment time and expenses due to meiimum usage of capab&ties oi modern software solutions.

Request for a quote

ZANDER GMBH

Germany

Bending forms for heat-set plastic pipes Our services We manufacture tools for the molding of plastic pipes according to datasets, drawings and geometric data for two processes: in a convection oven with water vapor Bending molds are in every respect sophisticated tools that meet the rapidly increasing demands of the automotive industry on your products.

Request for a quote

ZANDER GMBH

Germany

Three-dimensional shapes and tools implemented in steel and aluminum. Our services Moldmaking develops and manufactures tools for your products based on models, datasets and drawings. Manifold mandrels, tools for cooling water, fuel, heating and air hoses and other special applications Vulcanizing molds for air conditioning hoses with high accuracy in steel and aluminum Milling mandrels for hoses in stainless steel and aluminum Punching tools for elastomers Special production in steel, stainless steel and aluminum Turning - CNC machine CTX 420 with driven tools and Y-axis Milling - CNC machine DMU 80, five axes simultaneously

Request for a quote

FRIMO GROUP GMBH

Germany

Composites are engineered materials made from two or more materials with significantly different physical or chemical properties. Their mechanical and physical properties depend on the type and proportion of the base materials and the parameters of the manufacturing process. Due to composites, very light and durable plastic parts can be produced. Composites may be prepared as layers , fibers, particles or penetrating composites , but the actual composite material usually only arises during the shaping process in the tool . FRIMO has extensive technical expertise and many years of experience in developing and manufacturing plants and tools to process composite materials such as CFK, GFK, NFPP, HFPP, LFT, GMT and BMC and supplies for the production processes such as RRIM, SRIM / GMPU, Long Fiber Technologies, NFI, or RTM tailor-made manufacturing equipment.

Request for a quote

FRIMO GROUP GMBH

Germany

Successful for decades and constantly evolving Regardless of the desired kinematics, clamping force or clamping area, FRIMO customized tool/mold carriers can be integrated into single-station or multi-station units, rotary table systems or PURe Track overhead conveyors. FRIMO's more than 1,000 manufactured and delivered tool/mold carriers serve as proof of superior quality and reliability. Special Types: FRIMO is your specialist when it comes to optimal tooling concepts based on customer demands. Our product portfolio covers a broad spectrum of possible special designs, such as window frames, damping units, cast skins, skis, acoustic components, boilers, glass roofs, steering wheels, seat cushions and head rests.

Request for a quote

SCHOCK GROUP

Germany

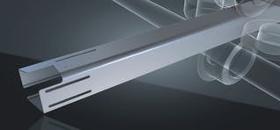

SCHOCK is your specialist in the production of cold-rolled profiles tailored to individual customer requirements. With a wide range of different technologies, we manufacture special profiles as customized functional elements up to complete assemblies. SCHOCK's roll forming technology operates economically and material-efficiently, offering significant advantages in product design: Unlimited range of shapes Highly precise functional dimensions Economical material utilization Energy-efficient manufacturing process SCHOCK special profiles are characterized by the highest precision and top-notch workmanship. With SCHOCK's roll forming technology, we produce profiles with extremely tight tolerances and excellent product properties. Thanks to creative tool solutions, we manufacture virtually burr-free profiles and process different materials with a tensile strength of up to 1000 MPa.

Request for a quote

SCHOCK GROUP

Germany

Precision in toolmaking is crucial for the quality of your products. Our experienced mold-making team manufactures your tools professionally and functionally. Your project is in the best hands at SCHOCK. Our experienced engineers plan all resources with the most modern methods and guarantee on-time production. Furthermore, we provide full lifecycle support for your tools. In mold and toolmaking, we utilize high-quality milling machines, wire and sinker EDM machines, as well as modern CNC-controlled grinding machines. Our service offerings in the field of injection mold tooling include, among others: Injection molds Multi-component molds (rotary tables, index plates, core-back, transfer technology) Insert technology Gas internal pressure (GID) Foil overmolding (IMD) Thermoset molds Prototype and small-series molds Injection molds: up to 1,000 x 800 mm and 2.5 tons Multi-component molds: rotary tables, index plates, core-back, transfer technology

Request for a quote

STRECKFUSS SYSTEMS GMBH & CO. KG

Germany

TYP C 043 Cutting, stamping and bending device for axial components Description The Streckfuss machine Type C 043 is designed, to cut stamp and bend axial leaded components for both horizontal and vertical mounting. To make the insertion of components with short leads into p. c. boards possible, the leads have to be cut to suitable length, bend to the required pitch and - if necessary- stamped. Both, suitable length and required pitch can be adjusted by adjusting screws. After this set- up the components can be processed. Option: the adjustments can be checked by a digital display. The stamping result for the leads depends on the used tool. These tools can be manufactured to meet customer requirements. The machine can be re- set for the different tools. The taped components can be processed automatically. The processing- speed is continuously variable. The tool change for different bending dimensions takes about 2 minutes. Components

Request for a quote

STRECKFUSS SYSTEMS GMBH & CO. KG

Germany

TYP C 043/ES Cutting, stamping and bending device for axial components Description To make the insertion of components with short leads into p. c. boards possible, the leads have to be cut to suitable length, bend to the required pitch and - if necessary- stamped. Both, suitable length and required pitch can be adjusted by adjusting screws. After this set- up the components can be processed. Cutting length and pitch are fully adjustable. The stamping result for the leads depends on the used tool. Leadforming ist tool specific and can be manufactured to meet customer requirements. The difference to the types C 043 and C 043 E is the integrated Pneumatic which makes the rearrangement of the Bending- and Formingtools possible. This means, that the tools can be approached to the components. Espacially bendings with Flush- Mount- bead can be done. The taped components can be processed automatically. The processing- speed is continuously variable. The tool change for different bending dimensions takes about 5 minutes. Components

Request for a quote

STRECKFUSS SYSTEMS GMBH & CO. KG

Germany

TYP C 043/E Cutting, stamping and bending device for axial components Description The Streckfuss machine Type C 043/E is designed, to cut stamp and bend axial leaded components for both horizontal and vertical mounting. To make the insertion of components with short leads into p. c. boards possible, the leads have to be cut to suitable length, bend to the required pitch and - if necessary- stamped. Both, suitable length and required pitch can be adjusted by adjusting screws. After this set- up the components can be processed. Option: the adjustments can be checked by a digital display. The stamping result for the leads depends on the used tool. These tools can be manufactured to meet customer requirements. The machine can be re- set for the different tools. The taped components can be processed automatically. The processing- speed is continuously variable. The tool change for different bending dimensions takes about 2 minutes. Components

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

Results for

Tool manufacturer - Import exportNumber of results

17 ProductsCountries

Company type