- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- rotary tables

Results for

Rotary tables - Import export

NORELEM FRANCE

France

Body and rotary table Al alloy, anodised. Spindle steel, casehardened. Spindle bearing maintenancefree. Position indicator plastic. Version Radial play of rotation axis < 0.015 mm. Axial play of rotation axis < 0.02 mm. Repeat accuracy < 0.05°. Spindle selflocking. Note 360° adjustment with no end stop. The position indicator displays in 0.1° increments clockwise. The angle of rotation is indicated directly on the large LCD display. The rotary stage rotates anticlockwise. Reset, chain dimension and offset settings can be made via the keypad. 2 years battery life. The battery is quick and easy to replace. The mounting position of the position indicator is set in 4 positions using one screw. Transmission ratio 211611008 = 501 211611012 = 551 211611025 = 501 The modular design enables the rotary stage to be easily combined with other items of the same size. Drawing reference Assembly position of position indicator a) top (standard) b) right c) bottom

Request for a quote

IGUS® GMBH

Germany

Universal glide elements – customise your own plain bearing supported rotary table systems Using the versatile iglidur® PRT universal glide elements, large slewing ring systems can be modeled tailored to the type 01. Depending on the number of elements, rotary table systems can be implemented with inner diameters ranging from approx. 0.5 to 5m. – we will gladly support you with the design and detailed layout. Universal gliding element, made from the proven iglidur® J Customize your own slewing ring tables starting at 500 mm diameters and larger Lubricant free Maintenance-free wear-resistant Rugged Resistant to corrosion Typical applications:Solar industry, assembly equipment, fixture making 1. Glide element made of iglidur® J Part number: JRS-500S/45S Material table General features Density 1,49 g/cm 3 Colour yellow Max. moisture absorption at 23 °C and 50 %r.h. 0,3 Wt.-% Max. water absorption 1,3 Wt.-% Mechanical properties Max. permissible static surface pressure (+20 °C) 35 MPa Shore D hardness 74 Physical and thermal properties Max. long term application temperature 90°C Max. short term application temperature 120°C Lower application temperature –50° Electrical properties Surface resistance >10 12 Ω loads up tp 10 tons

Request for a quote

NORELEM FRANCE

France

Body and rotary table Al alloy, anodised. Spindle steel, casehardened. Spindle bearing maintenancefree. Version Radial play of rotation axis < 0.015 mm. Axial play of rotation axis < 0.02 mm. Repeat accuracy < 0.05°. Spindle selflocking. Note 360° adjustment, no end stop. Scale graduation is 10 increments. Transmission ratio 2116008 = 501 2116012 = 551 2116025 = 501 The rotary stage can be easily combined with other modules of the same size. Drawing reference All counterbores to DIN 74Bm (D6)

Request for a quote

NORELEM FRANCE

France

Base and rotary table aluminium alloy. Hollow shaft stainless steel. Preloaded worm gear steel. Claw coupling aluminium with polyurethane coupling spider. Version Aluminium alloy anodised. Note for ordering The unit is supplied with the position of cable outlet or control unit as shown in the drawing. Note Rotary positioning stages for motorised adjustment and positioning tasks. The preloaded worm gear runs virtually playfree. The bearing of the worm shaft offers maximum radial rotational accuracy. Cables can be routed through the large bore in the hollow shaft. The adjustable positioning ring is used to determine the rotational reference point to the position of the assembled part. Proximity switches can be mounted with the optionally available sensor holder (21094). The suitable programming software and interface cable for the stepper motor with positioning control are available as accessories (2500015).

Request for a quote

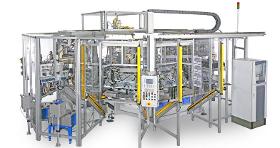

FRIMO GROUP GMBH

Germany

A concept for higher productivity FRIMO VarioForm inline and rotary table thermoforming machines are primarily used in the automotive industry and are ideally suited for forming a wide range of films and sheet materials.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

FRIMO GROUP GMBH

Germany

Good ergonomics and optimal component accessibility Milling can be used to not only create highly complex component geometries, but also to achieve precise cutting depths. It is often used in combination with punching operations to produce component variations or small quantities, such as of instrument panels, center consoles or door panels. FRIMO FlexTrim milling machines have been specially developed to process complex 3-D plastic components. The newest generation of FlexTrim milling machines offers an attractive price/performance ratio. The new rotary table and product fixture concept ensures excellent ergonomic conditions for the operator and optimal component access for the milling robots. The use of multiple product fixtures per station reduces the number of necessary changes, thereby increasing productivity. Through the use of new milling technology with optimized chips, an effectiveness ratio of up to 95 % is possible with appropriate material combinations.

Request for a quote

FRIMO GROUP GMBH

Germany

Successful for decades and constantly evolving Regardless of the desired kinematics, clamping force or clamping area, FRIMO customized tool/mold carriers can be integrated into single-station or multi-station units, rotary table systems or PURe Track overhead conveyors. FRIMO's more than 1,000 manufactured and delivered tool/mold carriers serve as proof of superior quality and reliability. Special Types: FRIMO is your specialist when it comes to optimal tooling concepts based on customer demands. Our product portfolio covers a broad spectrum of possible special designs, such as window frames, damping units, cast skins, skis, acoustic components, boilers, glass roofs, steering wheels, seat cushions and head rests.

Request for a quoteHERRMANN ULTRASCHALLTECHNIK GMBH & CO. KG

Germany

Rotary table machines are used for applications that involve production of large counts in cycle time-optimized manner. The machine design allows for dividing the application into several process steps. The number of operating stations depends on the respective task. The individual operating steps are performed in the different stations within the work space simultaneously with loading in the loading area. Indexed tool change is optionally possible.

Request for a quote

SCHOCK GROUP

Germany

Precision in toolmaking is crucial for the quality of your products. Our experienced mold-making team manufactures your tools professionally and functionally. Your project is in the best hands at SCHOCK. Our experienced engineers plan all resources with the most modern methods and guarantee on-time production. Furthermore, we provide full lifecycle support for your tools. In mold and toolmaking, we utilize high-quality milling machines, wire and sinker EDM machines, as well as modern CNC-controlled grinding machines. Our service offerings in the field of injection mold tooling include, among others: Injection molds Multi-component molds (rotary tables, index plates, core-back, transfer technology) Insert technology Gas internal pressure (GID) Foil overmolding (IMD) Thermoset molds Prototype and small-series molds Injection molds: up to 1,000 x 800 mm and 2.5 tons Multi-component molds: rotary tables, index plates, core-back, transfer technology

Request for a quote

HOCHRAINER GMBH

Germany

Rotary indexing assembly table for power window mechanism including testing station .

Request for a quoteResults for

Rotary tables - Import exportNumber of results

11 ProductsCountries

Company type