- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- position controller

Results for

Position controller - Import export

NORELEM FRANCE

France

2-phase high-torque stepper motor in NEMA 17, NEMA 23 and NEMA 34 sizes with flat-milled shaft (D-shaft). 1.8ׄ° increment angle (full increment) with integrated positioning control. Note: Stepper motor with integrated positioning control. It forms a convenient unit consisting of stepper motor and intelligent controller. Reference travel is possible on a block with reduced electric current without proximity switch. Integrated rotational monitoring. Smooth running through dynamic switching of increment trip. Actuation via single I/O interface, 31 position configurations and call-ups. Control unit can be parametrised quickly and conveniently with the software. The software and manual for programming the positioning control are available as free download. When selecting a suitable motor, using just the retaining torque is not enough, as the motor’s torque decreases with the speed. It is therefore essential to select the correct motor according to the torque curve.

Request for a quote

IGUS® GMBH

Germany

dryve motor control - Connect, select, control... Precise positioning, endless movements, continuous end-to-end movements - simply defined with the new control for drylin® E linear systems from igus®. - No software or app installation necessary - Quick commissioning - Compatible with numerous industrial controls (e.g. Siemens S7 / Beckhoff) - For stepper motors - Cost-effective

Request for a quote

IGUS® GMBH

Germany

dryve motor control - Connect, select, control... Precise positioning, endless movements, continuous end-to-end movements - simply defined with the new control for drylin® E linear systems from igus®. - No software or app installation necessary - Quick commissioning - Compatible with numerous industrial controls (e.g. Siemens S7 / Beckhoff) - For stepper motors - Cost-effective

Request for a quote

IGUS® GMBH

Germany

dryve motor control system - select, click, control... Travel distances, positions, speeds, operating times - easily defined with the new igus® web-based control system for drylin® E linear systems. - No software or app installation necessary, fast commissioning - Control possible via smartphone (browser), tablet or laptop - Simple and intuitive user interface, control system set up in just a few minutes - Compatible with numerous industrial controllers (e.g. Siemens S7/Beckhoff) - For DC, EC and stepper motors - Cost-effective

Request for a quote

NORELEM FRANCE

France

Bearing block and carriage aluminium alloy. Guide column and threaded spindle stainless steel. Plain bearing for guide columns and spindle nut highquality special plastic. Claw coupling aluminium with polyurethane coupling spider. Version Aluminium alloy anodised. Stainless steel hardened and ground. Threaded spindle with ball bearing. Note for ordering The unit is supplied with the position of cable outlet or control unit as shown in the drawing. Note Positioning stages for motorised adjustment and positioning tasks. The plain bearings and spindle nuts are suitable for dry running, however lubrication with a grease for plastic plain bearings is recommended. The suitable programming software and interface cable for the stepper motor with positioning control are available as accessories (2500015).

Request for a quote

NORELEM FRANCE

France

Base and rotary table aluminium alloy. Hollow shaft stainless steel. Preloaded worm gear steel. Claw coupling aluminium with polyurethane coupling spider. Version Aluminium alloy anodised. Note for ordering The unit is supplied with the position of cable outlet or control unit as shown in the drawing. Note Rotary positioning stages for motorised adjustment and positioning tasks. The preloaded worm gear runs virtually playfree. The bearing of the worm shaft offers maximum radial rotational accuracy. Cables can be routed through the large bore in the hollow shaft. The adjustable positioning ring is used to determine the rotational reference point to the position of the assembled part. Proximity switches can be mounted with the optionally available sensor holder (21094). The suitable programming software and interface cable for the stepper motor with positioning control are available as accessories (2500015).

Request for a quote

CIC - KLAUS CZERWONKA

Germany

Pneumatic cylinders according to the norm, standard or special design, completely configured ready for installation and pre-assembled with add-on parts, bearing elements, compressed air connections, position sensors or control valves according to customer specifications.

Request for a quote

NORELEM FRANCE

France

Pneumatic clamps have the following advantages compared to hand clamps: The operator is relieved of frequent clamping. Several clamps can be activated at the same time and can be closed in a specific sequence. Single or multiple clamps can be activated from varying positions by machine control or hand control. Because of the toggle system: the clamp remains closed if the air supply fails. the air consumption is low due to the large end ratio. pivoting the clamping arm achieves a large opening travel. optimum force and movement ratios are achieved. VL = air consumption per complete cycle in dm³ at 6 bar. Selection criteria: To select the correct size of pneumatic clamps, the possible clamping force at 6 bar (any compressed media are permissible, maximum pressure 10 bar) is specified besides the retaining force. F3 is the possible clamping force that the clamp exerts on the end of the clamping arm, F4 the force it exerts on the fulcrum side.

Request for a quote

AUTOMATION & ROBOTICS (A&R)

Belgium

The Focovision by Transmission SPV-3 is used in prescription laboratories. It is connected to your computer network, from which it receives the nominal values of the prescription lens. Its main advantages are repeatability, accuracy, easy calibration, and especially its visualization system of the semivisible marks or the upper segment line corner of the addition. This system permits an accurate positioning on the different control points without any lens marking. It measures the lens optical power by using a light beam perpendicular to the concave lens surface at a certain wavelength (546 nm or 587 nm) and by measuring in all directions (360 degrees). In addition, it has a user friendly interface permitting an operator to learn how to perform the complete lens control (far view, prism reference point, near view, thickness, shape, etc.) with little training required. Minimal training required Very high measurement speed Flexibility (configurable procedures, easy to adapt, any toleran

Request for a quote

MAXON MOTOR AG

Switzerland

The EPOS2 Module 36/2 is an OEM positioning controller plug-in module for brushed DC motors with encoder or brushless EC motors with Hall sensors and encoder up to 72 watts.

Request for a quote

MAXON MOTOR AG

Switzerland

The EPOS2 50/5 is a modular digital positioning controller. Matched with brushed DC motors with encoder or brushless EC motors with Hall sensors and encoder, from 5 to 250 watts.

Request for a quote

MAXON MOTOR AG

Switzerland

The EPOS2 24/2 DC/EC is a modular digital positioning controller. Matched with brushed DC motors with encoder or brushless EC motors with Hall sensors and encoder up to 48 watts.

Request for a quote

MAXON MOTOR AG

Switzerland

The EPOS2 24/2 EC is a modular digital positioning controller. Matched with brushless EC motors with Hall sensors and encoder up to 48 watts.

Request for a quote

MAXON MOTOR AG

Switzerland

The EPOS2 P 24/5 is a freely programmable positioning controller according IEC 61131-3. Matched with brushed DC motors with encoder or brushless EC motors with Hall sensors and encoder, from 5 to 120 watts.

Request for a quote

MAXON MOTOR AG

Switzerland

The EPOS2 70/10 is a modular digital positioning controller. Matched with brushed DC motors with encoder or brushless EC motors with Hall sensors and encoder, from 80 to 700 watts.

Request for a quote

MAXON MOTOR AG

Switzerland

The EPOS2 24/5 is a modular digital positioning controller. Matched with brushed DC motors with encoder or brushless EC motors with Hall sensors and encoder, from 5 to 120 watts.

Request for a quote

MAXON MOTOR AG

Switzerland

Staying in control has never been easier. Intelligent dc motor control electronics. All current, speed and position controllers are specially designed for brushed DC and brushless DC motors up to 700 W. CANopen or EtherCAT allow for easy integration of your network. The ESCON 4-Q servo controllers provide power and highly precise speed control for maxon brushed DC and brushless DC (maxon EC) motors , in a compact design. For simple speed control applications of brushless DC motors, we offer 1-Q servo amplifiers with a modular design available. All amplifiers feature a variety of useful additional functions. When more than just speed and torque control is required and recurring positioning processes with complex trajectories have to be executed use maxon positioning controllers. With the EPOS2 and EPOS3 (Easy Positioning System) controllers, a modular product line is available for DC brushed and brushless motors. The newest addition to the high-performance range of positioning controllers are the MAXPOS controllers. Current and speed controllers: DEC Module: 1-quadrant brushless DC (maxon EC) motor amplifier for speed control ESCON: 4-quadrant servo controller for current and speed control Positioning controllers: EPOS2: Easy Positioning System with CANopen interface and Interpolated Position Mode EPOS2 P: The programmable positioning controller with CANopen interface EPOS3: Easy Positioning System with EtherCAT interface and CoE (CAN application layer over EtherCAT) MAXPOS: High-performance positioning controller with EtherCAT interface and CoE (CAN application layer over EtherCAT)Cost-effective, Easy speed-control with Hall sensors up to 250 W.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

MAXON MOTOR AG

Switzerland

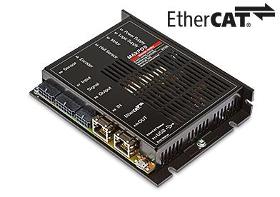

MAXPOS The high-performance positioning motor controller by maxon motor. MAXPOS 50/5 receives movement and I/O commands from a superior EtherCAT master, which carries out the process control. The extremely fast controllers and the diverse feedback options available provide the ideal conditions for the operation of permanent-magnet activated brushed and brushless DC motors in high-performance applications. Raising the bar for precision and synchronisation. MAXPOS 50/5 supports CoE (CAN application layer over EtherCAT). MAXPOS features The Feature Chart provides a quick overview of the most important features: MAXPOS integration MAXPOS Communication Guide provides hints for integration of MAXPOS into several EtherCAT master systems and further application support topics: MAXPOS 50/5 Part number 447293 For brushed DC motors with encoders and brushless DC (maxon EC) motors with Hall sensors and encoders up to 250 W. MAXPOS Setup (complete version) Installation includes: MAXPOS Studio 1.3 (graphical user interface) MAXPOS firmware 0x0121 Documentation (MAXPOS Feature Chart, MAXPOS Setup «Release Notes», Firmware Version of «Readme», Hardware Reference, MAXPOS Application Notes Collection, Firmware Specification, and Application Notes)EtherCAT interface, fast controllers, and diverse feedback options for the operation of brushed DC or brushless DC (maxon EC) motors.

Request for a quote

MECANUMERIC

France

Discover MECAJET the new range of Water Jet equipments conceived by MECANUMERIC, machining and cutting by VHP soft materials, and, with addition of abrasive, hard materials. Refer to the exemples of applications : Precision engineering technical parts Electric vehicles parts Parts for subways Parts for trams Bus parts Trolleys Household appliances Lights Furniture Weather vanes Discover the new range of very high pressure Waterjet equipment MECAJET designed and manufactured by MECANUMERIC, for cutting of several materials: * Soft materials: - rubber - plastics - leathers... * And, with addition of abrasive, hard materials: - metal - ceramic - glass - stone - composite materials... The MECAJET integrate the last novelties: driving system on POWER AUTOMATION numerical control (CN7100 ISO), new long-lasting pneumatic cutting heads, axes positioning control, 3 or 5 axes head, clearance control, etc... The cutting table is equipped with a steel welded one-block frame with...

Request for a quote

GLOBAL INDUSTRIAL SEWING MACHINES

Netherlands

3200 HFD 2000 (only delivered completely mounted and installed) – Semi automatic lockstitch curtain hook attaching machine with fully automatic curtain hook feeding device. • Versatile Global semi automatic high speed curtain hook attaching machine, for hook-sizes of 55 mm, 75 mm, 95 mm. • Quick load hook container, stores up to 100 hooks. • Fully automatic curtain hook feeding device with automatic adjustment of the hook-height between 5 and 50 mm in steps of 5 mm. • Sensor controlled positioning of the hook exactly under the needle. • Special tack program for fixation of the pleats ( separate operation). • Capacity up to 1500 hooks a day. 3200 HFD 2000 (only delivered completely mounted and installed) – Semi automatic lockstitch curtain hook attaching machine with fully automatic curtain hook feeding device. • Versatile Global semi automatic high speed curtain hook attaching machine, for hook-sizes of 55 mm, 75 mm, 95 mm. • Quick load hook container, stores up to 100 hooks. •...

Request for a quote

TQ SYSTEMS GMBH - PRODUKTBEREICHE

Germany

Flexible drive solutions through motors with RoboDrive technology Key functionalities High torque with compact design High power density through maximum copper fill factor Reduced power loss through optimized stator and rotor design Use as direct drive with reduced motor speed Highly precise controllability, positioning accuracy and dynamics High efficiency with compact design Modeled drive, tool-based optimization over the entire drive train Hollow shaft design

Request for a quote

TQ SYSTEMS GMBH - PRODUKTBEREICHE

Germany

SDB-40-100 Key functionalities: 100 kHz PWM rate Position-, speed- and torque control or mircro stepping mode Reference Specified values via fieldbus, parameter interface or analog control voltage Motor feedback via various encoder interfaces Acurate control of motion sequences with highest dynamics and precision Access to all relevant motor and control parameters Extended control and filtering capabilities in all control loops Extensive memory for real time logging Modulation of high electrical frequencies Availability: December 2015

Request for a quote

COMITRONIC BTI

France

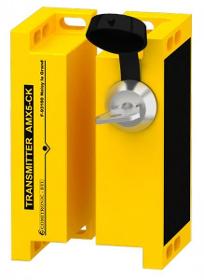

RFID sensor with 16 million codes Suitable for metallic environments Programmable code through auto-learning (no software or PC) Level of performance with AWAX controller: up to PL = e Safety category: up to 4 (EN 954-1) with AWAX controller Time to dangerous failure: MTTFd = 40 years Max activation distance: up to 24 mm Security contact/diagnostics: 2 x redundant NO 50mA/30V and 1 x 50mA auxiliary PNP Detection encoding: inviolable multicode Indicator: LED indicates code recognition Reset: automatic Attachment: 4 tamper-proof M4 screws (in base option: BH4) Mounting position: 2 (double wall brackets) Material: PA6 Electrical Connection: 50cm PUR cable with M12 connector Sealing: IP 67 Standing room temperature: -30 °C to +50 °C. Storage temperature: -40 °C to +85 °C Marking: pad printing + serial number for traceability Certificate: E2 10R-04 14053 (UTAC) ISO 7637-2 (Pulse 1, 2a, 2b, 3a, 3b, 4)

Request for a quote

COMITRONIC BTI

France

40N integrated stainless steel magnetic door holding Contactless coded electronic sensor Total safety management with an AWAX controller Level of performance with AWAX controller: up to PL = e Safety category: up to 4 with an AWAX controller Time before dangerous failure: MTTFd = 360 years Max. activation distance: 3 mm, 2 mm hysteresis Holding Force: transmitter + receiver in contact = 40N Safety contacts/diagnostics: 2 x NO 0.8A max / 48V redundant and 1 x PNP 250mA Detection encoding: mono-code inviolable Reset: automatic Attachment: 4 tamper-proof M4 screws (optional ref: BH4) Mounting position: 1 Material: INOX 316L mirror polished Electrical Connection: 3, 6, 12m cable or 50cm cord PUR M12 (ref. + MKT) Water resistance: IP 67/68 (EPINUS-4K-MKT) and IP 69K (EPINUS-4K/SES) Temperature: -25°C to +70°C. Marking: laser engraving with mechanical punching of the serial number for permanent traceability

Request for a quote

COMITRONIC BTI

France

High temperature, magnetic door holding, integrated 20N Contactless coded electronic sensor Total safety management with an AWAX controller Level of performance with AWAX controller: up to PL = e Safety category: up to 4 with an AWAX controller Time before dangerous failure: MTTFd = 100 years Max. activation distance: 3 mm, 1 mm hysteresis Holding Force: transmitter + receiver in contact = 20N Safety contacts/diagnostics: 2 x NO 0.8A/24V redundant and 1 x PNP 250mA Detection encoding: mono-code inviolable Reset: automatic Attachment: 4 tamper-proof M4 screws (optional ref: BH4) Mounting position: 2 (double wall brackets) Material: INOX 316L mirror polished Electrical connection: 50cm Ultra-soft silicone cord with M12 connector. Water resistance: IP 69K Extreme temperature: -40°C to +125°C Marking: laser engraving with mechanical punching of the serial number for permanent traceability

Request for a quote

COMITRONIC BTI

France

Manages person entry in hazard zones using an electrical locking key Contactless encoded electronic sensor with relay Category 3 total safety management without an external controller Electrical locking key with position contact Level of performance without an external controller: PL = d Level of performance with AWAX controller: up to PL = e Safety category without an external controller: 3 Safety Integrity Level: SIL 2 Cycle before dangerous failure: B10d = 2,000,000 at 2A Max. activation distance: 10 mm, 2 mm hysteresis Safety contacts/diagnostics: 2 x NO 2A/48V redundant / 2xPNP 250mA auxiliary (open/closed door and locking/unlocking of contacts) Detection encoding: mono-code inviolable Note: two-color LED indicates the key locking position; white LED indicates code recognition Reset: automatic Attachment: 4 tamper-proof M4 screws (optional ref: BH4) Mounting position: 2 (double wall brackets) Material: Polycarbonate Electrical connection: M12 metal base Water resistance: IP 65 Temperature: -15°C to +60°C Marking: screen printed + serial no. for traceability

Request for a quote

COMITRONIC BTI

France

Contactless encoded electronic sensor with relay Up to 8 zone differentiation codes Safety contacts 2A / 250V • Level of performance without an external controller: PL = c • Level of performance with AWAX controller: up to PL = e • Safety category without an external controller: 1 • Cycle before dangerous failure: B10d = 2,000,000 at 2A • Max. activation distance 3SSR24V/5SSR24BX/5SSR24BX-US: 8 mm, 2 mm hysteresis • Max. activation distance 2SSR24V/2SSR24BX: 4 mm, 2 mm hysteresis • Safety contacts/diagnostics 3SSR24V: 1 x NO 2A/250V / 1 x NF 2A/250V auxiliary • Security contacts/diagnostics 5SSR24BX and 5SSR24BX-US: 2 x NO 2A/250V / 1 x PNP NF 250mA auxiliary (24V) • Security contacts 2SSR24V: 2 x NO 2A/250V • Security contacts 2SSR24BX: 1 x NO 2A/250V and 1 x NF 2A/250V • Detection encoding 3SSR24V, 5SSR24BX/5SSR24BX-US: single inviolable code • Detection encoding 2SSR24V and 2SSR24BX: 8 inviolable codes • Indicators 2SSR24V, 2SSR24BX, 3SSR24V and 5SSR24BX: Red LED indicating code absence (not transmitter) • Indicator 5SSR24BX-US: Two-color red/green LED • Reset: automatic • Attachment: 4 tamper-proof M4 screws (optional ref: BH4) • Mounting position: 2 (double wall brackets) • Matierial PA6: 2SSR24V, 2SSR24BX, 3SSR24V, 5SSR24BX, 5SSR24BX-MKT and 5SSR24BX-US • Material INOX 316L mirror polished: 5SSR24BX-OX and 5SSR24BX-OX-MKT • Electrical Connection: 3, 6, 12m cable or 50cm cord with M12 connector (UL20549 PUR) for5SSR24BX-OX and 5SSR24BX-OX-MKT • Water resistance: IP 67/68 (PA6) or IP 69Kwith stainless steel - new generation • Temperature: -25°C to +60°C • Marking: PA6 pad printing + serial number, INOX316L laser engraving with mechanically punched serial number for permanent traceability

Request for a quote

COMITRONIC BTI

France

Contactless coded electronic sensor Total safety management with an AWAX controller High temperature Level of performance with AWAX controller: up to PL = e Safety category: up to 4 with an AWAX controller Time before dangerous failure: MTTFd = 100 years Max. activation distance: 10 mm, 2 mm hysteresis Safety contacts/diagnostics: 2 x NO 1A/24V redundant and 1 x 250mA PNP contact Detection encoding: mono-code inviolable Reset: automatic Attachment: 4 tamper-proof M4 screws (optional ref: BH4) Mounting position: 2 (double wall brackets) Material: INOX 316L mirror polished Electrical connection: 50cm Ultra-soft silicone cord with M12 connector. Water resistance: IP 69K Extreme temperature: -40°C to +125°C Protective cover 316L stainless steel mirror polished "ref. + C" option Marking: laser engraving with mechanical punching of the serial number for permanent traceability

Request for a quote

COMITRONIC BTI

France

Contactless coded electronic sensor Connectors / Wiring compatible with most hardware Suitable for grooved profiles Level of performance with AWAX controller: up to PL = e Safety category: up to 4 with an AWAX controller Time before dangerous failure: MTTFd = 100 years Max. activation distance: 8 mm, 2 mm hysteresis Safety contacts/diagnostics: 2 x NO 0.8A/24V redundant and 1 x 250mA PNP contact Detection encoding: mono-code inviolable Indicator: 1 LED indicating code recognition and 1 LED indicating code absence Reset: automatic Attachment: 4 tamper-proof M4 screws (optional ref: BH4). Suitable for grooved profiles. Screw caps provided. Mounting position: 1 Material: INOX 316L mirror polished Electrical connection: 2 x 50cm cords with M12 connector Water resistance: IP 69K Temperature: -30°C to +70°C. Marking: laser engraving with mechanical punching of the serial number for permanent traceability

Request for a quoteResults for

Position controller - Import exportNumber of results

48 ProductsCompany type