- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- oil separator

Results for

Oil separator - Import export

HORST WALBERG TROCKENFRUCHT IMPORT GMBH

Germany

Productinformation Spicy cashews, crisp and gently roasted peanuts and almonds with a fine roasted flavor are paired with sweet raisins, exotic coconut cubes and sweet roasted almonds. The result: an extremely tasty mix—our Sweet & Salty Mix. Try these perfectly matched tastes and flavors. Ingredients Almonds, raisins, cashews, peanuts, sugar, coconut and separating agent: vegetable oils, salt, chili powder, peanut oil, glucose, coloring: E150, preservative: E220, carrier: E414 Origin This is where the most exquisite ingredients from different parts of the world come together. Almonds are mainly from the USA, Spain, Italy, Australia, Chile, Portugal, Greece and Morocco. Cashew nuts are primarily grown in India, Brazil and Africa. The main producers of wine grapes are Chile, USA, South Africa and Turkey. The main areas for growing coconut include the Philippines, Indonesia, Sri Lanka and Thailand. Peanuts are cultivated worldwide in warm areas, but mainly in China and South America.

Request for a quote

OSMO MEMBRANE SYSTEMS GMBH

Germany

Oil-water-separation / degreasing bath treatment Treatment of oil-water-emulsions for surface treatment (e.g. pre-treatment of metal parts for ed-paint), recovery companies (e.g. for the treatment of alkaline emulsions for part washing), and so on. Separation of emulgated oil particles and recycling of the cleaned liquid into the degreasing bath Concentration of oil-water-emulsions for disposal Cleaning of the oil-water-mixture for indirect lead-in Principle of this process: Aqueous degreasing baths content a tenside combination, alkalines like soda, caustic soda, phosphate, silicate and further complex molecules. The degreasing bath is loosing its efficiency, when to oil content reaches some g / litre. External pollutions also degrease the degreasing efficiency. By ultrafiltration, the oil content can be separated from the degreasing bath and the oil will be collected in the concentrate. The degreasing bath will be dumped into a buffer tank and then pumped in the working tank of the

Request for a quote

OSMO MEMBRANE SYSTEMS GMBH

Germany

Disposal of oil emulsions by ultrafiltration Increasing disposal costs and laws about oil disposal make a treatment of oily emulsions right necessary right where they come up. The main target of this treatment is the reduction of waste volume as much as possible. Ultrafiltration is one possibility to separate even stabile emulsions. Like chemical methods and flotation, ultrafiltration can not be used as stand-alone solution. Only by an effective pre-treatment and a pre-treatment of the oily concentrate, an optimized and economical emulsion disposal can be guaranteed. By the pre-treatment, coarse particles and free oil is separated; the pre-separation dewaters and concenctrates the flow, which comes as concentrate from the ultrafiltration. So, a maximum of dewatering and concentration of the oil can be reached. The emulsion is pumped through the membrane modules of the plant. On the membrane surface, oil is separated from the waste water. Waste water will pass the membrane and is colle

Request for a quote

OSMO MEMBRANE SYSTEMS GMBH

Germany

Degreasing bath treatment Ultrafiltration is established for a long time for applications like treatment of emulsions, degreasing baths or craft detection oils. With ultrafiltration, oil and dirt particles are separated. So, the particle-free filtrate can be used for degreasing again. According to the recommendations of suppliers for degreasing chemicals tensides are added to the degreasing bath. So, lifetimes up to 3 to 6 months can be reached for degreasing baths. Osmo Membrane Systems GmbH offers an upgrade for your degreasing plant in replacing the polymer pipe modules by ceramic modules. Ceramic modules are more temperature resistant, chemical resistant and changing pH-values. On the one hand, the separation efficiency will be increased and on the other hand, the lifetime of the degreasing plant will be increased significantly, because polymer modules have to be changed much more, depending on the application. The costs for the upgrade are equal to the costs for working with poly

Request for a quote

NASH - ZWEIGNIEDERLASSUNG DER GARDNER DENVER DEUTSCHLAND GMBH

Germany

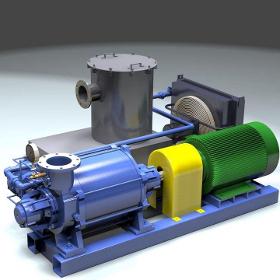

0-29 in HgV (to 33 mbar abs) If you thought you couldn't afford the water costs associated with operating a liquid ring pump…think again. One of the wonderful features of the liquid ring pump is that it can be operated with a multitude of different fluids. A self-contained oil sealed system has a number of benefits over a traditional water sealed system: It eliminates water usage and disposal costs; it allows you to install it in remote locations where water may not be available; it allows you to attain higher vacuum levels than with water; it can prevent the condensing or dissolving of a process gas; it permits anhydrous processing with a liquid ring pump. Self contained system complete with off of the components for your basic operating needs. Standard components include: pump, TEFC motor, coupling or v-belt drive, drive guard, separator with oil mist eliminator, air cooled heat exchanger, recirculated seal line controls and high temperature alarm switch. Options include: inlet isolation valve, inlet check valve, vacuum relief valve, inlet filter, control panel and system skid plate. An oil sealed liquid ring system is more tolerant of carryover and wear, and it provides quiet operation. The oil is not required for lubrication which means it can operate at extremely long intervals between oil changes, easily going more than 10,000 hours with no down time. Aside from a periodic oil and filter change, the system can run for years with no scheduled maintenance. If your process requires very deep vacuum, Gardner Denver Nash has the solution. Using a two-stage liquid ring pump in an oil sealed system, vacuum levels lower than 10 Torr (29.6" HgV) can be attained.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

Results for

Oil separator - Import exportNumber of results

5 ProductsCountries

Company type

Category