- europages

- >

- COMPANIES - SUPPLIERS - SERVICE PROVIDERS

- >

- large weld

Results for

Large weld - Import export

MAGAGER, UNIPESSOAL, LDA

Portugal

SMART, COMPACT MULTI-PROCESS Lincoln Electric's Weld Pak 2000 is a complete multi-process continuous voltage arc welding machine ideal for welding thin sheets and repair and maintenance work. This machine is a perfect tool for light steel applications and is mobile, meaning the operator can easily move this MIG welding machine to any location in the workshop. Weld Pak 2000 is recommended for MIG/MAG applications, for arc welding with Innershield gas-free flux-cored core and applications with Rutile and Basic electrodes. This machine is designed to feed wire from 0.6 mm to 1.1 mm (steel, stainless steel and flux cored) on B300 and S200 coils. High quality welding performance that depends on a quality wire drive system. Lincoln Electric has equipped the Weld PAK with a professional feeder with large rollers. The Weld Pak 2000 is designed to meet Lincoln performance and reliability standards. : Compact design with a standard

Request for a quote

MARXAM PROJECT

Poland

All required protective coatings are made in certified external companies. The basic condition for cooperation is meeting all environmental requirements. Our capabilities include the following metal protective coatings: - aluminum anodizing (soft and hard); - cataphoresis (electrophoretic painting); - electropolishing; - galvanic zinc; - hot-dip galvanized (galvanizing metal); - powder coating. As a production company, we offer: - metal sandblasting of crude steel; - removing paint coatings by sandblasting and soda blasting (without heating and damaging the surface); - glass blasting of stainless steel and aluminum; - unifying the surface after machining and welding; - large-area painting with a hydrodynamic, airless unit.

Request for a quote

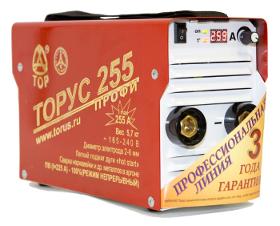

COMPANY TOR

Russia

TORUS-255 has the widest possible range of arc welding currents (from 20 to 255 A), which makes it possible to use it both for welding very thin metals, including in the TIG mode (welding with non-consumable electrode), and for continuous welding of large metal structures using an electrode up to 6 mm in diameter. The operating margin in the ТОРУС-255 device is such that it can be effectively used not only for the MMA and TIG modes, but also in the surfacing and cutting modes. At the same time, the weight of the device itself is traditionally not big – only 5.7 kg. Like all devices of the ТОРУС line, ТОРУС-255 has increased reliability with all its maximum parameters. A 3-year manufacturer’s warranty is a guarantee of its high performance in the most severe operating conditions.

Request for a quoteHERRMANN ULTRASCHALLTECHNIK GMBH & CO. KG

Germany

The ultrasonic actuators of the TWINLINE product line are used for solving weld tasks with a Herrmann Ultrasonic 20 kHz twin sonotrode. The finely tuned twin-stack is mounted on a carriage. The construction and design principle allows for large weld forces and high precision. This product line also provides a number of variants.

Request for a quoteHERRMANN ULTRASCHALLTECHNIK GMBH & CO. KG

Germany

Optimal machine design for 20 kHz applications for which the joining process must be precisely performed by several sonotrodes in a single weld process. The rigid sonotrode support is realized by means of individual alignment modules and allows for accurate positioning even at large weld forces. Contrary to conventional designs, the weld stroke is performed by the anvil. During this stage, the plastic parts to be welded are moved against the stationary sonotrodes. Thus, it is possible to obtain machine cycle times of less than 10 seconds.

Request for a quote

W&K METALLVERARBEITUNG GMBH

Germany

• TIG welding: The letters TIG stand for tungsten inert gas welding and generally belong to the inert gas welding process. In this welding process, an arc burns between a tungsten electrode (non-consumable) and the workpiece. The electrode, the arc and the molten bath are protected from the atmosphere by an inert gas. • MIG / MAG welding: The letters MIG stand for metal inert gas, the letters MAG for metal active gas. This welding process is also part of the group of metal inert gas welding processes. In this welding process, a consumable wire electrode is fed continuously. The arc burns between the supplied wire and the workpiece. Throughout the welding process, the arc and the weld pool are protected by either an active gas (MAG process) or an inert gas (MIG process). This welding process can be used for a variety of materials and is also available for a large number of welding consumables.

Request for a quoteDo you sell or make similar products?

Sign up to europages and have your products listed

Results for

Large weld - Import exportNumber of results

6 ProductsCountries

Company type